Rise and Fall of Rethink Robotics

Rise and Fall of Rethink Robotics

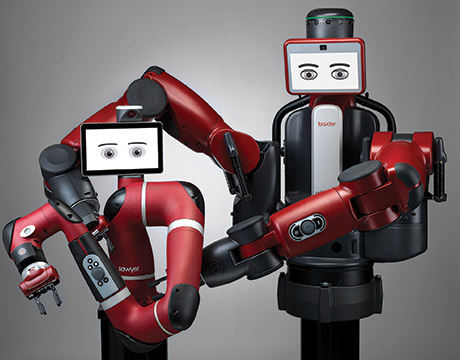

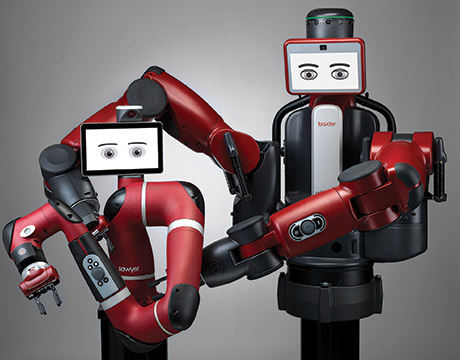

Two-armed Baxter and more precise one-armed Sawyer industrial robots. Image: Rethink Robotics

Ten years ago, Universal Robots and Rethink Robotics burst onto the scene with seemingly similar breakthrough products—small, light-weight, easy-to-program industrial robots that were safe enough to work next to people on the factory floor.

Both companies made collaborative robots, or cobots. Both based their designs on conventional robotic arms, but their products were smaller, slower, and less powerful than industrial robots. Unlike their industrial cousins, which were kept behind cages to prevent injuries to workers, they were outfit with sensors and could stop on a dime if the cobots sensed an impact with an object or person.

But the similarities between Rethink and Universal stopped there.

Boston-based Rethink Robotics shut its doors in October, 2018, and sold its patents, technology, and intellectual property to a former distributor.

Denmark’s Universal, with revenues approaching $250 million, has become the clear cobot leader, and recently scooped up more than 20 former Rethink employees.

Why did one company succeed while the other crashed and failed? Robotics experts, investors, and customers tell a complicated story of how Rethink’s designs failed to meet the needs of its target market, small- and medium-sized manufacturers.

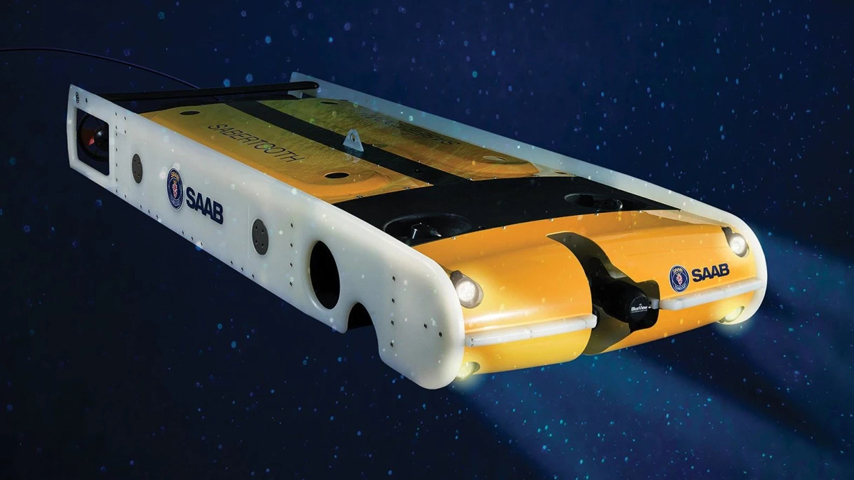

Join ASME and Leading Industry Experts for Offshore Wind Turbine Webinar series

Further, its pioneering technology made it difficult to fix problems in its two-armed Baxter and one-armed Sawyer robots. They suffered because Rethink prioritized safety and cost over speed and precision and baked those decisions into the hardware itself. Those design choices limited the type of applications where the robots could be used as well as the company’s ability to reengineer the robots to improve their performance.

Universal succeeded because its robots were accurate and repeatable, yet safe enough to work next to people.

“And because they did that, they took over the market,” said Gary McMurray, an associate director of Georgia Institute of Technology’s Institute for Robotics and Intelligent Machines and a board member of the Robotic Industries Association.

Read ASME’s Top Story: Air Taxi Aces Test Flight

In 2015, Universal sold the company to Teradyne Inc. of North Reading, Mass., a much larger test and industrial automation company. That proved a game-changer, accelerating Universal’s already rapid growth.

“A lot of people realized, ‘Yeah, this game’s over,’ ” McMurray said. “Teradyne didn’t jump into Rethink. They jumped into Universal because they did their due diligence and saw who was succeeding and who could scale and who couldn’t.”

;custompagebreak;ELASTIC ACTUATORS

Rodney Brooks was already a robot rock star when he cofounded Rethink Robotics with Ann Whittaker in 2008. He headed MIT’s Computer Science and Artificial Intelligence Lab, and had cofounded iRobot, best known for its quirky Roomba autonomous vacuum robot, with two MIT grads in 1990.

Brooks drew a team of engineers and researchers from MIT to Rethink, including electrical engineer Matthew Williamson, who became director of technology development. At MIT, Williamson had earned a Ph.D. developing series elastic actuators. They consisted of a motor and gearbox linked to an elastic actuator, which behaved like a spring.

Elastic actuators were a sharp break from the past. Universal’s articulated arm robots, for example, used powerful motors, precision gearboxes, and external sensors to position the robot accurately. It also mounted dual sensors in each arm joint to measure the slightest impact. If it felt a bump, its robust drive system could stop the arm in milliseconds. Series elastic actuators worked differently. Because they used elastic rather than rigid actuators, they absorbed shocks if they hit someone, giving the robot additional time to apply the brakes.

Read ASME Long-form Story on Robots: Robots to the Rescue

The actuators doubled as force sensors. By measuring the elastic’s deformation, the robot could measure the amount of force at the end of the arm. It could use force sensing to feel its way in when aligning a circuit board on a testing device or signal a stop if it hit someone. Baking the force actuators into the hardware made Rethink’s robots inherently safer around people, Williamson argued.

Best of all, series elastic actuators promised lower costs. They used lighter motors than rigid actuators and their springiness made up for the mechanical irregularities of cheaper gearboxes.

It seemed like a good idea to Paul Maeder, a mechanical engineer who founded Highland Capital Partners in Cambridge, Mass. He invested early in Rethink Robotics in 2010 and sat on its board.

“The notion was that rather than using very expensive high-precision motors, you could use cheap motors and use force sensing to determine your [exact] position,” Maeder said. “Then you could make a much less expensive robot.”

Rethink’s Sawyer sold for around $26,000 with accessories, according to Maeder. Universal’s robots start closer to $50,000, according to the company.

There were, of course, tradeoffs. Series elastic actuators and force sensing were not as accurate as conventional positioning systems.

“In the end, the series elastic actuators were probably not the best idea in the world,” Maeder said. “What customers really want is a low-cost, simple, fast, repeatable robot. They want to put something in this exact location again, and again and again. In the end, that was a lot more complicated for us to achieve than for some of our competitors because they weren’t trying to do force sensing.”

While the hardware was less expensive, the software required to compensate for the elastic actuators was more expensive, he added. And because the actuators were baked into the design, it was impossible to modify the robot without starting from scratch, Maeder said.

Instead, Rethink started looking for markets where or in which precision did not matter as much. That eliminated packaging and most assembly, but still left machine tending. Yet even that was a challenge.

Rapid-Line, a metal fabricator in Grand Rapids, Mich., bought two Baxter robots in 2015, said Ben Robbert, an account manager and sales representative with the company. Their job was to load and unload CNC machines. While the robots could work alongside people, they were not precise enough and would miss their marks, Robbert said.

Listen to the latest episode of ASME TechCast: Breakthrough Could Bring New Cancer Treatment

“We didn’t always feel like we were getting the best return because we spent a lot of time troubleshooting,” Robbert said.

When orders dropped for the light part the Baxters tended, Rapid-Line sold the robots. Yet employees remained intrigued by the benefits of collaborative robots.

“We haven’t written them off,” Robbert said. “We understand they will progress and evolve.”

;custompagebreak;TOO MUCH FLEXIBILITY

Another selling point for Rethink’s robots was their adaptability. In a 2012 YouTube video presentation before an audience of engineers, Brooks admitted that Baxter’s reliance on force sensing made it a poor choice for precision tasks. Still, he argued, users could teach Baxter new tasks faster and more safely than other robots on the market—without a dedicated programmer.

“Whether we can convince people that these are important metrics is an unknown question, because they are a different set of metrics.” Brooks added.

It turns out that Rethink over-valued flexibility. Manufacturers, Maeder explained, do not move their manufacturing lines often and cared little about the speed at which they could retrain their robot.

Nor did customers know what to do with Baxter’s two-armed design. They preferred a traditional single-arm robot. “In the end,” Maeder said, “the things that Rethink spent a lot of money to develop, the customers didn’t care that much about.”

Others pointed to missteps in accessories. Baxter and Sawyer came with several end effectors and an embedded vision system. While they were useable out of the box, their closed architecture made them difficult to customize with third-party options.

Cox Container, for example, bought a Sawyer. Yet it had to go to a local machine shop to make a custom end effector to pick up empty half-gallon plastic containers and pack them in a bin in its Troy, Ala., plant.

Plant Manager Gary Fox said Rethink couldn’t help him buy or develop what Sawyer needed. Then, Sawyer’s software upgrade downloaded improperly and Rethink again was unable to help.

While that was “frustrating,” Fox was happy with Sawyer’s performance and let Rethink make a video of the robot in action. But his next robots will likely come from Universal, since Cox’s new owner uses them. They are “significantly faster and the movements are smoother and not as jerky.”

Of four customers interviewed for this story, only Cox still uses its Rethink robots. One never put it into use because the application it was bought for went away, while the other reconfigured its operation.

Read another Long-form Story on Energy Disruptors: Startup Suns

Despite raising $150 million from such major investors as Goldman Sachs, Wellington Management, and GE Ventures, Rethink was hemorrhaging cash. Rather than sinking more cash into the business, the board went shopping for a firm to acquire Rethink.

Rethink’s preferred acquirer, a Chinese company, backed out fearing possible disapproval by the Committee on Foreign Investment in the United States, Maeder said. A Treasury Department agency, CFIUS investigates whether foreign investments in U.S. companies might pose national security risks. This little-known agency often focuses on Chinese company deals.

Instead, Rethink shut its doors in early October. By the end of the month, the board had sold its Sawyer robots, intellectual property, patents, and licenses to Germany’s Hahn Group, an industrial automation firm that distributed Sawyer robots.

;custompagebreak;RISING COMPETITION

Universal Robots had a different trajectory. Founded in 2005, the Danish company created the cobot market when it launched its first UR robot in 2008, three years before Rethink.

UR’s design was not a radical break from the past. It resembled conventional robotic arms, just smaller, slower, and less dangerous. Yet it shared their precision and repeatability.

Like Rethink, Universal focused on small- to medium-sized manufacturers. Unlike Rethink, sales grew 700 percent annually in the early years, said Universal cofounder and chief technology officer Esben Hallundbæk Østergaard.

“Bottom line, we were first on the market and had a good product,” Østergaard said. “That’s hard to compete with. You need to have a better product or be first on the market.”

Universal’s business model differed from Rethink’s. Rather than provide an integrated system, it sold only robotic arms and embraced an open architecture that made it easy to add third-party sensors, cameras, grippers, and other accessories. This enabled users and integrators to customize robots for specific tasks.

That proved critical to Universal’s rapid growth. “We make one product, make it universal, and just ship a lot of that one product,” Østergaard said.

Read about Robotic Engineer’s Career Path: The Rise from BattleBot to Corporate Robot

Universal reached $38 million in 2014 and the company was profitable. Yet the company reached out to find an acquisition partner that could lift sales to the next level. While the firm was winning against Rethink, it saw competition coming from cobots under development by established industrial robot makers like ABB, Fanuc, Kuka Robotics, and Yaskawa Electric.

In 2015, Universal accepted a merger proposal from Teradyne. Teradyne paid $284 million in cash plus up to $65 million more if Universal met certain performance targets through 2018.

Teradyne chose Universal when looking for a complementary business to supplement its strong but relatively slow-growing electrical test business, said Andrew Blanchard, vice president of corporate relations.

Universal “had the best hardware, software, and operating model along with a strong technical and business leadership team,” he said.

The deal seems to have worked out. Sales neared $250 million in 2018, up roughly 50 percent for the year, said Stu Shepherd, regional sales director for the Americas for Universal USA.

At the time of the acquisition, Teradyne was a well-managed company with revenues of $1.6 billion and global reach. It immediately began re-engineering Universal’s supply chain. It tapped existing suppliers to negotiate lower prices, signed multiple vendors to guard against shortages, and improved warehousing strategy. On the manufacturing side—Universal built its own robots, unlike Rethink—it simplified assembly and improved quality. Today, typical delivery time is two to six weeks, Shepherd said.

;custompagebreak;THE COBOT MARKET

Two years ago, Universal created an online marketplace that makes it easier for customers to tap into its growing ecosystem of accessory providers.

These efforts have been “absolutely critical” to the company’s growth, Shepherd added. Meanwhile, industrial robot manufacturers are taking aim at the cobot space.

Japan’s Fanuc is one of them. A subsidiary of Fujitsu, it is a major robot supplier to automakers. It proved a simple pivot to provide collaborative robots that do not sacrifice speed and precision for safety, said Claude Dinsmoor, general manager of Fanuc’s general industry and automotive segment.

“We took a different approach,” he explained. Universal and Rethink limited robot speed and payload to reduce the force of any impact. Fanuc, on the other hand, started with standard industrial robots and added safety sensors to sense and avoid collisions. The final device was deemed safe by TÜV SÜD, a German inspection and product certification business.

The result is a faster, more powerful robot that can lift 35 kilograms—more than twice as much as Universal’s largest UR robot—yet is safe enough to work outside a cage.

It solves a real need faced by manufacturers, Dinsmoor said: “I’ve got to be able to work at a speed I need to make money, to reach the work piece, and pick up the payload. And I’ve got to be able to do it precisely enough to add value.”

Listen to ASME TechCast: How a High School Senior Helped a Wounded Marine

Fanuc also makes smaller cobots, which are used to flip burgers in a restaurant and fry chicken tenders at Dodger Stadium in Los Angeles, he added.

Dinsmoor, like Universal’s Shepherd, declined to speculate on why Rethink Robotics was not a success. “It takes a lot of work to succeed in this industry,” he said. “There are winners and losers all the time.”

Competition is likely to grow even more intense. Traditional industrial robot players, such as Fanuc, ABB, Epson, Kuka, and Yaskawa, have all launched new cobots. Startups, such as Carbon Robotics, Modbot, Productive Robotics, and TM Techman are also vying for a place on factory floors.

There may be room for all of them, at least in the beginning. There are nearly 300,000 small and medium sized factories in the United States alone. Many will embrace safe, accurate, easy to use cobots if they can boost productivity.

Even so, the marketplace is demanding, and some robots will undoubtedly fail.

Others will rise from disaster. While Rethink the company is dead, its technology will live on. Hahn, which acquired Rethink’s intellectual property, intends to license Rethink’s intuitive Intera robot software to other companies and perhaps build a new Sawyer-type robot arm.

It is less clear if it will use serial elastic actuators.

Carol Lawrence is a technology writer based in Los Angeles, Calif.

Register today for ASME’s Offshore Wind Summit to learn about the latest technologies, opportunities and supply chain strategies from leaders in the oil, gas and wind energy industries.

Read Latest Exclusive Stories from ASME.org: The Engineering Behind Brain Research Engineers Making Waves in Aquaculture Shrinking an Exhaust Resonator for New Automotive Design

In the end, the series elastic actuators were probably not the best idea in the world. What customers really want is a low-cost, simple, fast, repeatable robot.Paul Maeder, Highland Capital Partners