3D-Printed Cement Improves Crack Resistance

3D-Printed Cement Improves Crack Resistance

Additive manufacturing of cement-based materials, such as concrete and mortar, is a top research objective in the construction industry, with several start-up’s having already shown its feasibility. However, concerns exist about the durability and resilience of such printed structures, in part because the inherent weakness that exists along the interfaces created by the layer-by-layer AM methods, where brittle failure can occur.

Current efforts to solve this problem are focused on strengthening the interfaces through technical improvements to the 3D-printing process. Researchers at Purdue University, however, have taken a different approach. Inspired by novel structures found in the exoskeletons of arthropods such as lobsters and beetles, the team has successfully 3D-printed hardened cement paste (HCP) that actually controls cracking underload, just like arthropod shells do.

For You: Is This the Most Wear-Resistant Material in the World?

These naturally occurring structural patterns or architectures, generate unique damage-control mechanisms such as interfacial microcracking and crack twisting. That “allows inherently brittle HCP materials to attain flaw tolerant properties and novel performance characteristics,” said Mohamadreza Moini, a research team member. “These mechanisms lead to damage delocalization in brittle 3D-printed architectured HCP, resulting in quasi-brittle behavior, enhanced fracture and damage tolerance, and unique load displacement response, all without sacrificing strength.”

The team’s goal was to 3D-print elements made from cement-based materials that take advantage of unique structures found in arthropod shells to minimize the damage that can spread between printed layers of a material.

“The layered structures produced during layer-by-layer printing can result in weak interfaces between those layers,” Moini said. “In turn, these interfaces provide predefined paths for cracks to follow during the loading of the structure. Depending on the architecture and geometry of these interfaces, the growing crack eventually runs into an interface and initiates the growth of other cracks, thus spreading the distribution of damage and delaying damage localization, which ultimately leads to catastrophic failure of the material.”

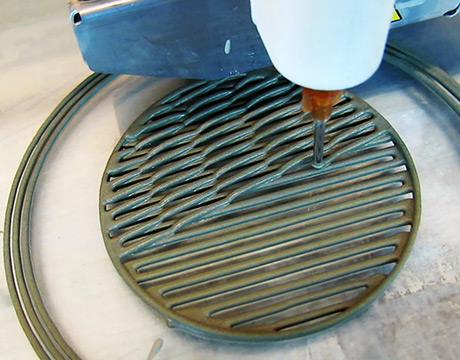

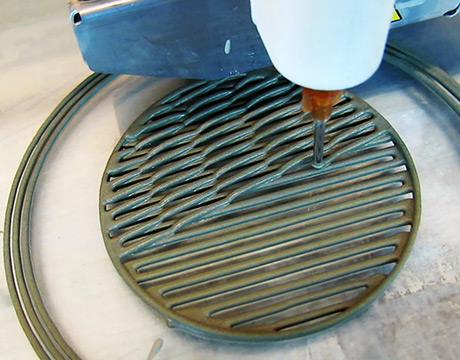

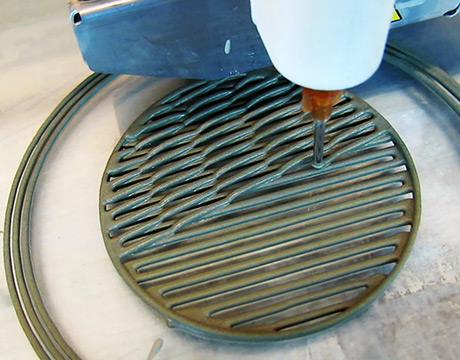

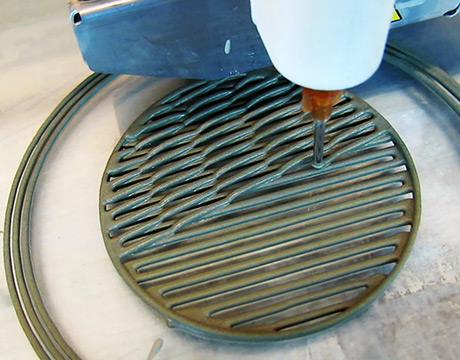

The most promising architectures fabricated with cement-paste materials include honeycomb, compliant, and Bouligand (helicoidal) structures. Using a 3D-printer and cement-paste materials, HCP elements can be printed to include these fundamental structural patterns. Each architecture results in new behaviors in a 3D-printed element. For example, the Bouligand architecture takes advantage of weak interfaces to make a material more crack-resistant; whereas the compliant architecture makes cement-based elements act like a spring, even though they are made of brittle material.

Micro-computed tomography examined the microstructure and the architectural patterns of the deposited materials to provide a deeper understanding of weak zones in the structure, such as pore regions found at the interfaces between the printed layers, which promote cracking.

Although the team expected that 3D-printing of particular structures would result in performance characteristics that are unattainable in cast counterparts, “We did not expect to see the observed level of increase in toughness of brittle, cement-based materials as a result of controlling their architecture,” Moini said. “For example, Bouligand architectures enhance inelastic deflection of the HCP elements by over 50 percent, when compared to traditionally cast elements from the same materials.”

Future Possibilities

3D printing can create architectures that allow brittle cement-based materials to achieve flaw-tolerant properties at larger structural scales or to bend without breaking. In the future, such architectures may be incorporated in structures undergoing vibrations to generate energy when coupled with a piezoelectric device. Helicoidal architectures can be incorporated in the design of structural elements, such as beams and columns of the building or concrete pavements and provide additional toughness and increased longevity.

The team plans to explore other types of materials-processing techniques and architectures that may improve performance of cement-based materials at larger scale.

“Understanding materials properties in a fresh state in order to suitably control the shape-holding capacity of the printing materials is also something we will focus on in future,” Moini said. “Another area of future research is the combination of cementitious materials with other materials to improve mechanical properties and add functionality. Self-healing and thermal adaptation will be some of the future topics given current technology and research in the general area of multifunctional materials.”

Mark Crawford is an independent writer.

For You: 4D Printing Advances Additive Manufacturing Unique Gas Turbine Engine Powers Quieter, More Reliable Drones The Upswing of Innovation

3D printing can create architectures that allow brittle cement-based materials to achieve flaw-tolerant properties at larger structural scales, or to bend without breaking. Mohamadreza Moini, Purdue University