Engineers Create Wikipedia for Hardware Projects

Engineers Create Wikipedia for Hardware Projects

Site hosts free blueprints to make turbines, biodigesters, solar cookers, bicycles, and more.

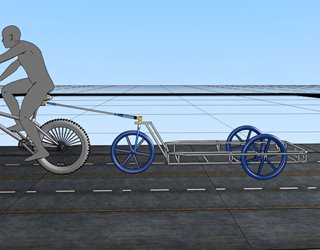

Home chefs rely on cookbooks for inspiration and step-by-step instructions. Now, a group of German engineers has created a website that acts much like a cookbook for hardware-based projects, providing blueprints for turbines, biodigesters, solar cookers, bicycles, and more. The designs are open source, meaning anyone can replicate a design and make a product without paying a license fee.

The Open Hardware Observatory can trace its roots back eight years, when engineers saw a boom in do-it-yourself projects with open-source electronics. OHO is trying to replicate an open-source hardware model in electronic design to the realm of mechanical engineering. The OHO website launched last year as a way to give engineers and non-engineers—especially in countries with limited access to technology—the knowhow to create simple products with off-the-shelf parts, and to fabricate it locally.

The designs, which are available as PDFs or in CAD file format, are “low tech and frugal on cost,” said Robert Mies, who is a chairman of OHO.

“You can make functional wind turbines with a basic set up of a metal workshop,” Mies said. “Mainly, we are just focusing on mechanical design because it’s a difficult thing today to accomplish.”

The obvious inspiration for OHO is the Open Source Hardware Association, a nonprofit that qualifies and certifies electronic designs in which many projects are rooted around computing boards like Arduino and Raspberry Pi.

“If you have an electronics project, there are many well-documented projects,” Mies said. “But if you have a project that has mechanical components, we don’t see many examples of advanced projects in which designs are documented and shared. There is a gap in practice.”

At a grassroots level, the OHO repository also brings visibility to everyday work done by non-engineers like mechanics who may not identify as open-source hardware developers, said Michael Weinberg, executive director at New York University Law’s Engelberg Center on Innovation Law and Policy.

“It includes people who are tinkerers, local craftspeople or tradesmen, who are fixing and building, and all sorts of creative things,” said Weinberg, who is also a lawyer involved with the Open Source Hardware Association.

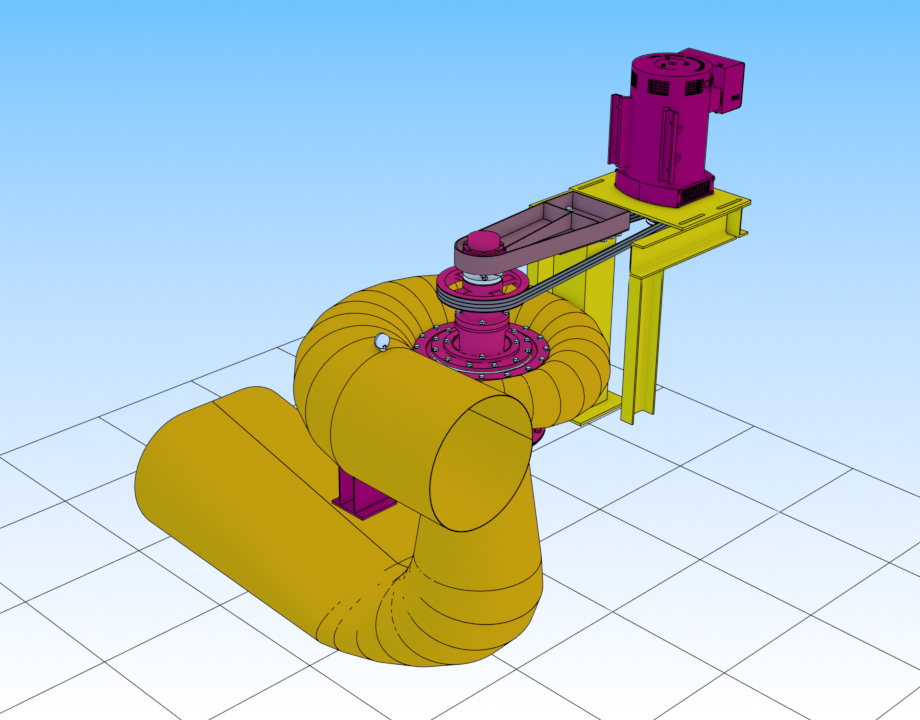

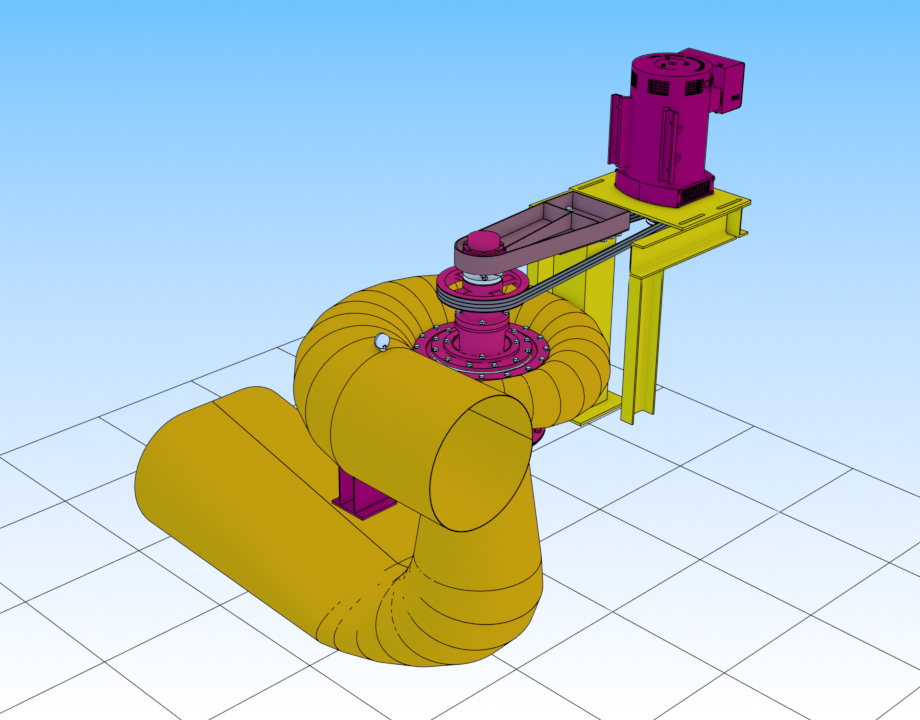

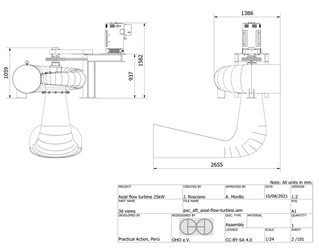

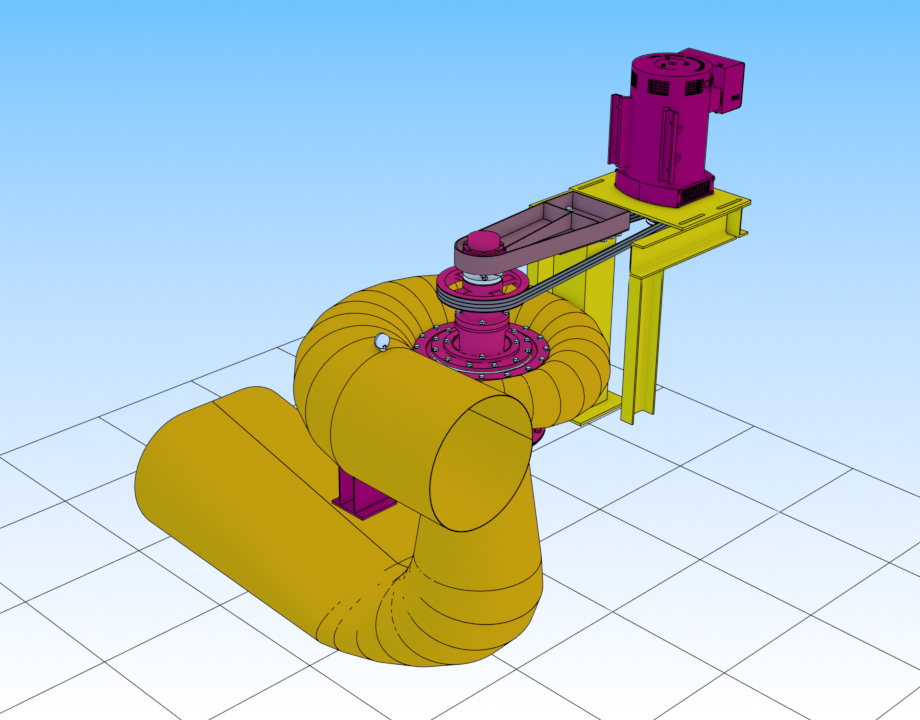

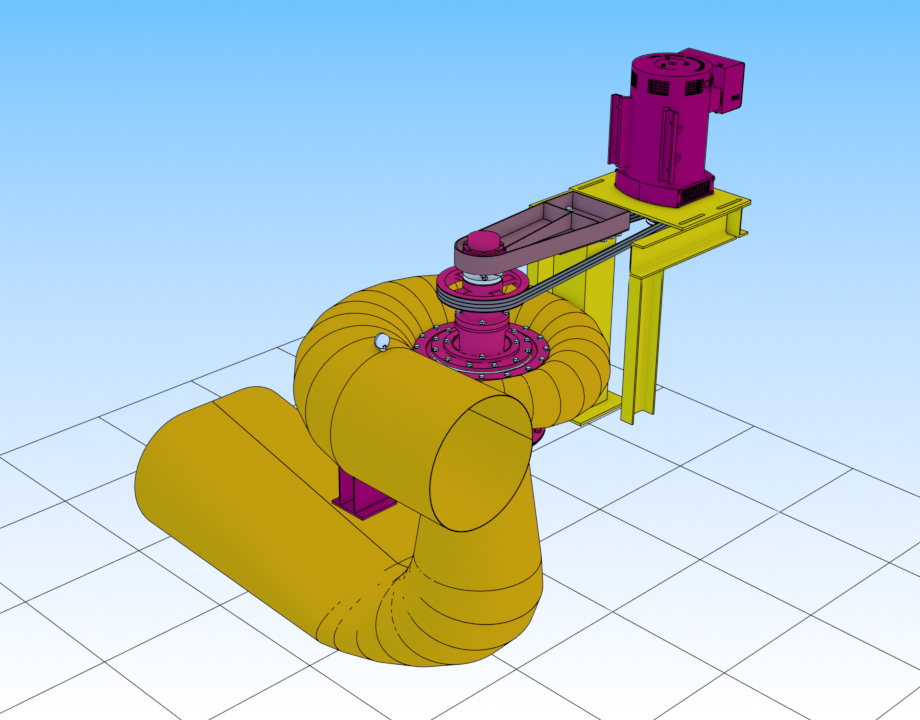

The documents curated on the website include both technical drawings and parts lists. For example, an axial flow turbine design, which was submitted by U.K and Peru-based Practical Action, is a 24-page PDF that includes the list of parts, assembly information, and three-dimensional technical drawings.

More on Open-Source Projects: Open-Source Software Boosts Quadrapedal Robot

In some cases, blueprints are accompanied with YouTube videos to provide guidance on projects. Two reviewers must clear every component and the design, after which the project is approved. The website was created in partnership with Wikimedia Foundation, which runs Wikipedia and other community-driven projects.

The OHO website publishes projects that are certified alongside guidelines established with the DIN-3105 specification established by Deutsches Institut für Normung (DIN), a German standardization body affiliated with ISO (International Organization of Standards).

“The certification is not a product certification where you qualify the project according to existing standards. The certification mainly checks this replicability criterion that DIN-SPEC 3105 asks for,” said Dietrich Jaeger, another chairman at OHO.

OHO has so far acquired and certified design published by non-profit organizations and universities. There is no system in place for OHO to check projects on patents, but the technologies involved are so basic that the organizers believe there is little need to worry about violating intellectual property. Jaeger provided one example for Savonius rotor in turbines, which cannot be patented. “It’s built by thousands of people in thousands of ways. So, nobody has a patent for this equipment,” he said.

As long as OHO is certifying projects that are built on common knowledge, the risk of patent violations is low, Weinberg said. “The question that they’re answering is, does this thing comply with the DIN spec or not? As someone who visits the site, if it’s all compliant within a specification, then that’s a useful piece of information.”

In addition, the OHO founders are trying to be realistic about fabrication of equipment. For instance, the organization is not prioritizing 3D printing—which has emerged in recent years as a way to localize production—as a fabrication technique. In many parts of the world, 3D printing is neither economically viable nor easily accessible, so the focus is on production via readily available facilities like metal or wood workshops.

Editor's Choice: Open Source Engineering Creates Great Ideas for Rural Areas

“We are not talking mainly about 3D printing or CNC milling. If we are looking at underdeveloped and developing countries or even in Germany, 3D printing is a good hobby,” Jaeger said.

Even with the focus on projects for the developing nations, Mies and Jaeger acknowledged challenges ahead. “We participated in conferences with development organizations, Engineers Without Borders, and others. They really don’t know or even heard of the concept of open hardware,” Jaeger said.

Another challenge is engaging more to participate in design peer reviews and building a community to share ideas and improve designs, which is central to the open-source ethos.

More participants will “ensure that certain things in place to be made aware if there are legal issues or safety issues,” Mies said.

Agam Shah is a business and technology writer based in New York City.

The Open Hardware Observatory can trace its roots back eight years, when engineers saw a boom in do-it-yourself projects with open-source electronics. OHO is trying to replicate an open-source hardware model in electronic design to the realm of mechanical engineering. The OHO website launched last year as a way to give engineers and non-engineers—especially in countries with limited access to technology—the knowhow to create simple products with off-the-shelf parts, and to fabricate it locally.

The designs, which are available as PDFs or in CAD file format, are “low tech and frugal on cost,” said Robert Mies, who is a chairman of OHO.

“You can make functional wind turbines with a basic set up of a metal workshop,” Mies said. “Mainly, we are just focusing on mechanical design because it’s a difficult thing today to accomplish.”

The obvious inspiration for OHO is the Open Source Hardware Association, a nonprofit that qualifies and certifies electronic designs in which many projects are rooted around computing boards like Arduino and Raspberry Pi.

“If you have an electronics project, there are many well-documented projects,” Mies said. “But if you have a project that has mechanical components, we don’t see many examples of advanced projects in which designs are documented and shared. There is a gap in practice.”

At a grassroots level, the OHO repository also brings visibility to everyday work done by non-engineers like mechanics who may not identify as open-source hardware developers, said Michael Weinberg, executive director at New York University Law’s Engelberg Center on Innovation Law and Policy.

“It includes people who are tinkerers, local craftspeople or tradesmen, who are fixing and building, and all sorts of creative things,” said Weinberg, who is also a lawyer involved with the Open Source Hardware Association.

The documents curated on the website include both technical drawings and parts lists. For example, an axial flow turbine design, which was submitted by U.K and Peru-based Practical Action, is a 24-page PDF that includes the list of parts, assembly information, and three-dimensional technical drawings.

More on Open-Source Projects: Open-Source Software Boosts Quadrapedal Robot

In some cases, blueprints are accompanied with YouTube videos to provide guidance on projects. Two reviewers must clear every component and the design, after which the project is approved. The website was created in partnership with Wikimedia Foundation, which runs Wikipedia and other community-driven projects.

The OHO website publishes projects that are certified alongside guidelines established with the DIN-3105 specification established by Deutsches Institut für Normung (DIN), a German standardization body affiliated with ISO (International Organization of Standards).

“The certification is not a product certification where you qualify the project according to existing standards. The certification mainly checks this replicability criterion that DIN-SPEC 3105 asks for,” said Dietrich Jaeger, another chairman at OHO.

OHO has so far acquired and certified design published by non-profit organizations and universities. There is no system in place for OHO to check projects on patents, but the technologies involved are so basic that the organizers believe there is little need to worry about violating intellectual property. Jaeger provided one example for Savonius rotor in turbines, which cannot be patented. “It’s built by thousands of people in thousands of ways. So, nobody has a patent for this equipment,” he said.

As long as OHO is certifying projects that are built on common knowledge, the risk of patent violations is low, Weinberg said. “The question that they’re answering is, does this thing comply with the DIN spec or not? As someone who visits the site, if it’s all compliant within a specification, then that’s a useful piece of information.”

In addition, the OHO founders are trying to be realistic about fabrication of equipment. For instance, the organization is not prioritizing 3D printing—which has emerged in recent years as a way to localize production—as a fabrication technique. In many parts of the world, 3D printing is neither economically viable nor easily accessible, so the focus is on production via readily available facilities like metal or wood workshops.

Editor's Choice: Open Source Engineering Creates Great Ideas for Rural Areas

“We are not talking mainly about 3D printing or CNC milling. If we are looking at underdeveloped and developing countries or even in Germany, 3D printing is a good hobby,” Jaeger said.

Even with the focus on projects for the developing nations, Mies and Jaeger acknowledged challenges ahead. “We participated in conferences with development organizations, Engineers Without Borders, and others. They really don’t know or even heard of the concept of open hardware,” Jaeger said.

Another challenge is engaging more to participate in design peer reviews and building a community to share ideas and improve designs, which is central to the open-source ethos.

More participants will “ensure that certain things in place to be made aware if there are legal issues or safety issues,” Mies said.

Agam Shah is a business and technology writer based in New York City.