6 Steps in Selecting an Ac-Dc Power Supply

6 Steps in Selecting an Ac-Dc Power Supply

Learn the different design considerations when selecting an ac-dc power supply.

When selecting an ac-dc power supply, the primary consideration in determining the system power requirements. This includes the ac input range and the dc output specifications.

The user should verify the ac input voltage range of the power supply is compatible with their target markets and specified applications. The required input voltage operating range for most low or medium power ac-dc supplies is standardized worldwide to 85~264 Vac. There are specifications for different countries, but they are similar enough that the single specification range can meet the needs of most applications.

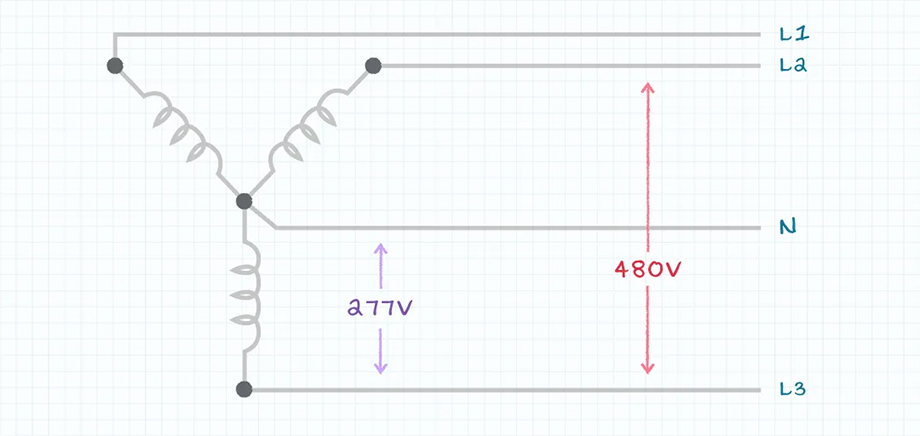

Japan has one of the lowest nominal input voltage requirements (100 Vac), while the UK, Canada, and the US have among the highest nominal input voltage requirements (240 Vac). The minimum standardized range value of 85 Vac is derived from allowing a 15% voltage drop of 100 Vac, while the 264 Vac maximum range value is derived from allowing operation at 10% above 240 Vac. One higher (and less common) voltage specification found in industrial applications is 277 Vac. This voltage is obtained by connecting between the phase and neutral of a 480 Vac Wye configuration. A maximum voltage of 305 Vac for this configuration is calculated by applying the previously discussed 10% tolerance above the 277 Vac rated voltage.

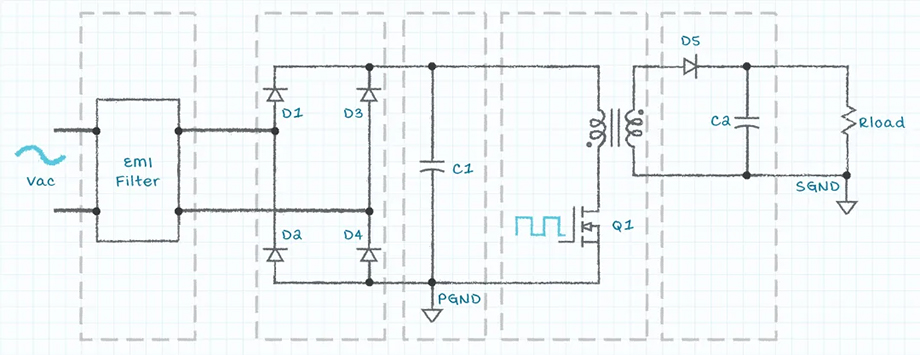

Inside ac-dc power supplies, the ac input voltage is typically immediately rectified to a dc voltage. On many ac inputs supplies, a dc voltage can be applied to the supply’s input, with the rated dc voltage range being calculated as 1.4 times the rated ac voltage range. Users should verify the power supply development team has evaluated the supply for use with a dc input voltage if they plan to use a dc input configuration.

While the input voltage for ac-dc supplies is standardized over a range, the output voltages are most common at the specific values of 5, 12, 24, or 48 Vdc. There are many ac-dc power supplies available with output voltages other than these, but there will be a more extensive selection of standard supplies available if the system loads are designed to use one of the common voltage levels. Suppose the standard output voltages are not proper for the system. In that case, other possible options may include: finding a standard power supply with the required dc output voltage, locating a power supply vendor willing to provide a custom design with the required output voltage, or using a dc-dc converter to create the required dc voltage.

Recommended for You: Three Charts about the Electric Grid

The required output power (or load current) is an important consideration when selecting an ac-dc power supply. The peak power drawn by the load determines the required rating of the power supply. A power supply with a greater rating than the load requires will work fine but maybe larger or more expensive than necessary. A power supply with a smaller power rating than the load requires may shut down or provide an incorrect output voltage due to peak power demands from the load. Some vendors offer ac-dc power supplies designed to provide high peak power for a short duration, minimizing the size and cost of the supply.

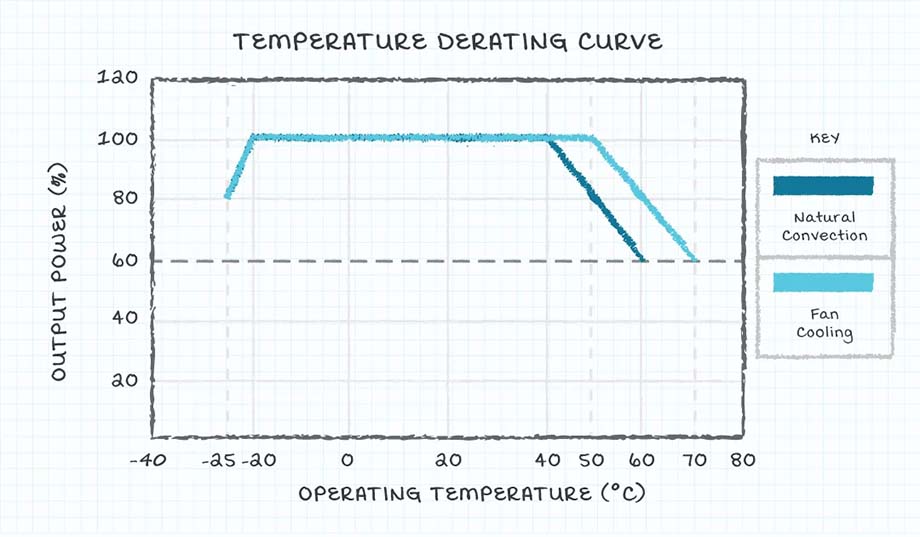

The environment a power supply operates in will affect the selection of an ac-dc power supply. Most power supply operating temperature specifications include derating factors for extreme cold and hot temperatures. Cold temperature power derating is often due to the temperature coefficient of capacitors used in the design of the supplies. Capacitance values typically drop with decreasing operating temperature. This means the specified output load current from the supply will also decrease. At high ambient temperatures, the maximum operating temperature of the components internal to the power supply will limit the load power that can be delivered. The maximum output power rating for many supplies can be increased by blowing air at the supply to assist in cooling the internal components.

In addition to the operating temperature range, there may also be physical characteristics of the operating environment that can influence the required features of the power supply. Power supplies enclosed in a metal case may be required if the electronics need to be physically protected from large foreign objects. While a metal case will not protect the power supply circuit from dust and dirt, a conformal coating can be applied to the internal circuit board to provide the required protection. Preventing objects from accidentally connecting to exposed input and output terminals can be accomplished by the addition of insulating terminal covers.

You May Also Like: How to Connect Power Supplies in Parallel or Series for Increased Output Power

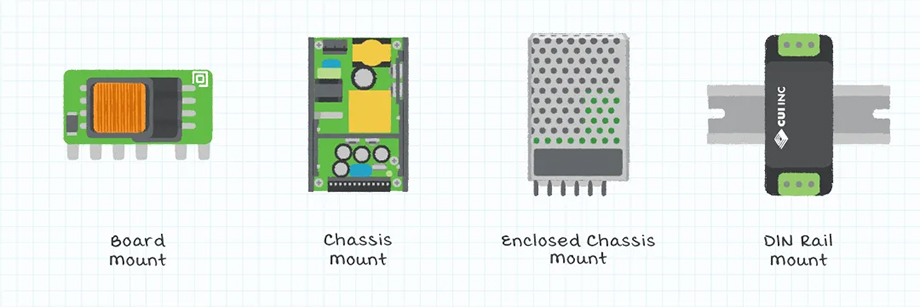

Ac-dc power supplies are available in potted, open frame, U-frame, enclosed frame, and fan-cooled packaging. The choice of packing configuration may be driven by the need to keep objects or contaminants out of the power supply. Users may also have the choice of PCB, chassis, or DIN rail mounting. Often, the same power supply series will be available in multiple mounting styles. The mounting style is usually determined by the mechanical environment in which the power supply will be used.

Many products will require operational and safety regulatory certificates for the ac-dc power supplies used in those products. Some common regulatory requirements include 60601 (medical), 60335 (household appliances), and 62368 (audio, video, and information and communication technologies). The power supply vendor will be able to provide copies of the applicable certificates to either the product development team or the testing facility granting the certificates to the final system. Some common regulatory agencies include UL, TUV, IEC, EN, FCC, and CISPR.

In addition to the ac-dc power supply characteristics discussed previously, some supplies provide additional features which may be beneficial or required in product designs. Some of these include:

Standard internal ac-dc power supplies are available in numerous configurations to meet the needs of most design projects. It may be beneficial for the design engineer to look at the web page or talk with a representative of the power supply vendor to ensure they are selecting the optimum power supply for their product. Power supply companies with experienced teams, such as CUI, are willing to assist in selecting a power supply.

Aaron Yarnell is a senior product manager for CUI Inc. He has nearly 15 years of experience in the electronics industry, covering a wide breadth of product technologies with responsibilities ranging from product design and development to field applications support, manufacturing, technical writing, and more.

The user should verify the ac input voltage range of the power supply is compatible with their target markets and specified applications. The required input voltage operating range for most low or medium power ac-dc supplies is standardized worldwide to 85~264 Vac. There are specifications for different countries, but they are similar enough that the single specification range can meet the needs of most applications.

1) How to Select the Correct Input Voltage?

Japan has one of the lowest nominal input voltage requirements (100 Vac), while the UK, Canada, and the US have among the highest nominal input voltage requirements (240 Vac). The minimum standardized range value of 85 Vac is derived from allowing a 15% voltage drop of 100 Vac, while the 264 Vac maximum range value is derived from allowing operation at 10% above 240 Vac. One higher (and less common) voltage specification found in industrial applications is 277 Vac. This voltage is obtained by connecting between the phase and neutral of a 480 Vac Wye configuration. A maximum voltage of 305 Vac for this configuration is calculated by applying the previously discussed 10% tolerance above the 277 Vac rated voltage.

Inside ac-dc power supplies, the ac input voltage is typically immediately rectified to a dc voltage. On many ac inputs supplies, a dc voltage can be applied to the supply’s input, with the rated dc voltage range being calculated as 1.4 times the rated ac voltage range. Users should verify the power supply development team has evaluated the supply for use with a dc input voltage if they plan to use a dc input configuration.

2) How to Select the Dc Output Voltage?

While the input voltage for ac-dc supplies is standardized over a range, the output voltages are most common at the specific values of 5, 12, 24, or 48 Vdc. There are many ac-dc power supplies available with output voltages other than these, but there will be a more extensive selection of standard supplies available if the system loads are designed to use one of the common voltage levels. Suppose the standard output voltages are not proper for the system. In that case, other possible options may include: finding a standard power supply with the required dc output voltage, locating a power supply vendor willing to provide a custom design with the required output voltage, or using a dc-dc converter to create the required dc voltage.

Recommended for You: Three Charts about the Electric Grid

3) Be Mindful of the Load Current

The required output power (or load current) is an important consideration when selecting an ac-dc power supply. The peak power drawn by the load determines the required rating of the power supply. A power supply with a greater rating than the load requires will work fine but maybe larger or more expensive than necessary. A power supply with a smaller power rating than the load requires may shut down or provide an incorrect output voltage due to peak power demands from the load. Some vendors offer ac-dc power supplies designed to provide high peak power for a short duration, minimizing the size and cost of the supply.

4) Where is the Power Supply Operating?

The environment a power supply operates in will affect the selection of an ac-dc power supply. Most power supply operating temperature specifications include derating factors for extreme cold and hot temperatures. Cold temperature power derating is often due to the temperature coefficient of capacitors used in the design of the supplies. Capacitance values typically drop with decreasing operating temperature. This means the specified output load current from the supply will also decrease. At high ambient temperatures, the maximum operating temperature of the components internal to the power supply will limit the load power that can be delivered. The maximum output power rating for many supplies can be increased by blowing air at the supply to assist in cooling the internal components.

In addition to the operating temperature range, there may also be physical characteristics of the operating environment that can influence the required features of the power supply. Power supplies enclosed in a metal case may be required if the electronics need to be physically protected from large foreign objects. While a metal case will not protect the power supply circuit from dust and dirt, a conformal coating can be applied to the internal circuit board to provide the required protection. Preventing objects from accidentally connecting to exposed input and output terminals can be accomplished by the addition of insulating terminal covers.

You May Also Like: How to Connect Power Supplies in Parallel or Series for Increased Output Power

5) Selecting the Right Fit and Framing

Ac-dc power supplies are available in potted, open frame, U-frame, enclosed frame, and fan-cooled packaging. The choice of packing configuration may be driven by the need to keep objects or contaminants out of the power supply. Users may also have the choice of PCB, chassis, or DIN rail mounting. Often, the same power supply series will be available in multiple mounting styles. The mounting style is usually determined by the mechanical environment in which the power supply will be used.

6) Confirm Operational and Safety Regulations

Many products will require operational and safety regulatory certificates for the ac-dc power supplies used in those products. Some common regulatory requirements include 60601 (medical), 60335 (household appliances), and 62368 (audio, video, and information and communication technologies). The power supply vendor will be able to provide copies of the applicable certificates to either the product development team or the testing facility granting the certificates to the final system. Some common regulatory agencies include UL, TUV, IEC, EN, FCC, and CISPR.

Additional Ac-Dc Power Supply Features

In addition to the ac-dc power supply characteristics discussed previously, some supplies provide additional features which may be beneficial or required in product designs. Some of these include:

- Discrete output voltage levels (available in most supplies).

- Provisions for the user to adjust the output voltage by as much as 10%.

- The output terminals on some supplies can be connected in parallel to increase the maximum current supplied to the load.

- Some high current output supplies have remote output voltage sense terminals to allow for compensation of the voltage drop along output power delivery conductors.

- Input power factor correction is often available for high power supplies.

- A remote on/off terminal will allow the user to switch the output of the supply with an electronic signal, while a power good terminal will provide a signal indicating the output voltage is within the regulation tolerance.

Standard internal ac-dc power supplies are available in numerous configurations to meet the needs of most design projects. It may be beneficial for the design engineer to look at the web page or talk with a representative of the power supply vendor to ensure they are selecting the optimum power supply for their product. Power supply companies with experienced teams, such as CUI, are willing to assist in selecting a power supply.

Aaron Yarnell is a senior product manager for CUI Inc. He has nearly 15 years of experience in the electronics industry, covering a wide breadth of product technologies with responsibilities ranging from product design and development to field applications support, manufacturing, technical writing, and more.

.png?width=854&height=480&ext=.png)