Carbon Structures Enhance Sodium-Ion Battery Performance

Carbon Structures Enhance Sodium-Ion Battery Performance

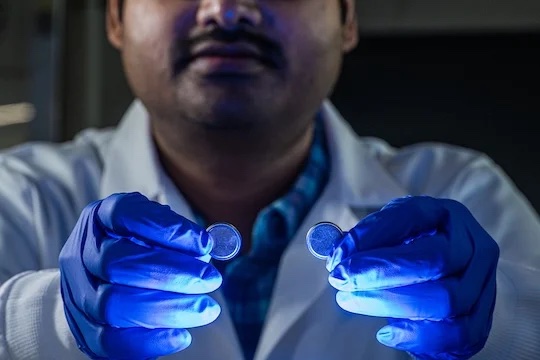

Using a graphite anode comprised of micro-sized disc and cone shapes can dramatically improve the flow of sodium ions in sodium-ion batteries.

To meet the growing demand for electric vehicles (EVs) and renewable energy storage, mechanical engineers are developing more affordable and sustainable battery technologies. Lithium-ion batteries remain the front runner; however, the rising cost and uneven global distribution of lithium have highlighted the urgent need for alternative battery technologies.

One of these technologies is the sodium-ion battery, in part because sodium is less expensive and more widely available than lithium. However, the graphite anodes used in lithium-ion batteries do not work well with sodium (Na) transport due to the limited diffusion and intercalation of Na ions into the graphite lattice. Thus, the challenge continues to be finding carbon-based anode materials that can efficiently store these larger ions.

Intent on finding a viable graphite material that can host larger alkali ions, researchers from Rice University, Baylor University, and the Indian Institute of Science Education and Research Thiruvananthapuram experimented with the shape of the electrodes, rather than their chemistry, to develop a promising battery system that dramatically improves the flow of sodium ions. This possible breakthrough could lead to the commercialization of Na-ion batteries.

“This realization opened a new direction: Exploring pure graphitic morphologies as scalable and efficient anode alternatives to conventional hard carbons for beyond-lithium batteries,” said postdoctoral associate Atin Pramanik, a member of the research team and professor Pulickel Ajayan's Ajayan Research Group at Rice University.

One of the biggest challenges in developing graphite cone/disc anodes for sodium batteries was overcoming the long-standing limitation of poor Na-ion intercalation in conventional graphite, due to size mismatch and structural incompatibility. Traditional graphite anodes are electrochemically inactive for sodium because Na ions are too large to fit into the tightly packed graphite layers.

You Might Also Enjoy: New Model Could Support Better Battery Design

To address this, the researchers engineered a graphitic structure that could accommodate larger ions without requiring heteroatom doping or introducing porosity, which often compromises structural integrity. Another significant challenge was proving and characterizing the ion intercalation mechanism in these novel morphologies. This required extensive and technically demanding testing to confirm the reversible intercalation of Na and K ions, distinguish between intercalation and surface adsorption, and evaluate potential lattice expansion without structural degradation.

“Developing a scalable, heteroatom-free, structurally optimized graphitic material and then rigorously validating its performance and mechanism posed substantial experimental and analytical hurdles,” Pramanik said.

“Furthermore, we thoroughly investigated the sodium storage mechanism within this cone/disc graphitic carbon, revealing how its structure supports efficient sodium-ion storage,” Pramanik said. “Our findings highlight one of the most promising performances of graphitic carbon anodes for sodium-ion batteries to date.”

Discover the Benefits of ASME Membership

In the absence of heteroatoms, these graphitic carbon structures exhibit excellent Na-ion intercalation, displaying a reversible capacity of approximately 230 mAh g−1 at a current rate of 20 mA g−1 and demonstrating excellent rate performance. The electrode also exhibited outstanding performance in K-ion intercalation. Ex situ transmission electron microscopy analysis and solid-state nuclear magnetic resonance spectroscopy proved the intercalation of sodium and potassium, revealing the charge storage mechanism.

Mechanically, the robust graphitic framework exhibits minimal volume expansion, even over 2,000 cycles at high current density (10 A g⁻¹), showcasing exceptional cycling stability, which is “critical from an engineering durability standpoint,” Pramanik said. “This integration of industrial scalability, electrochemical performance, and structural stability highlights a mechanically resilient and electrochemically efficient design, pushing the frontier of graphitic materials in beyond-lithium energy storage.”

“Scaling up electrode fabrication for practical full-cell configurations, possibly with alternative cathode materials and electrolytes, will be crucial for commercial viability,” Pramanik said.

In addition, exploring electrolyte-electrode interfacial chemistry, particularly the evolution and stability of the solid electrolyte interphase during long-term cycling, will be crucial.

“This work also opens up potential for similar graphitic structures in other beyond-lithium battery systems,” Pramanik said. “Moreover, their ability to be produced from industrial waste through an environmentally benign process adds value in sustainability-driven applications across energy, environmental remediation, and even electromagnetic shielding technologies.”

Mark Crawford is a technology writer in Corrales, N.M.

One of these technologies is the sodium-ion battery, in part because sodium is less expensive and more widely available than lithium. However, the graphite anodes used in lithium-ion batteries do not work well with sodium (Na) transport due to the limited diffusion and intercalation of Na ions into the graphite lattice. Thus, the challenge continues to be finding carbon-based anode materials that can efficiently store these larger ions.

Intent on finding a viable graphite material that can host larger alkali ions, researchers from Rice University, Baylor University, and the Indian Institute of Science Education and Research Thiruvananthapuram experimented with the shape of the electrodes, rather than their chemistry, to develop a promising battery system that dramatically improves the flow of sodium ions. This possible breakthrough could lead to the commercialization of Na-ion batteries.

Eureka

The “aha” moment came when the team encountered tiny, uniquely structured graphitic carbon cones and discs with a pure graphitic structure—an oil-and-gas industry byproduct derived from hydrocarbon pyrolysis. This material showed a surprising ability to reversibly intercalate these larger ions without requiring heteroatom doping or structural modification.“This realization opened a new direction: Exploring pure graphitic morphologies as scalable and efficient anode alternatives to conventional hard carbons for beyond-lithium batteries,” said postdoctoral associate Atin Pramanik, a member of the research team and professor Pulickel Ajayan's Ajayan Research Group at Rice University.

One of the biggest challenges in developing graphite cone/disc anodes for sodium batteries was overcoming the long-standing limitation of poor Na-ion intercalation in conventional graphite, due to size mismatch and structural incompatibility. Traditional graphite anodes are electrochemically inactive for sodium because Na ions are too large to fit into the tightly packed graphite layers.

You Might Also Enjoy: New Model Could Support Better Battery Design

To address this, the researchers engineered a graphitic structure that could accommodate larger ions without requiring heteroatom doping or introducing porosity, which often compromises structural integrity. Another significant challenge was proving and characterizing the ion intercalation mechanism in these novel morphologies. This required extensive and technically demanding testing to confirm the reversible intercalation of Na and K ions, distinguish between intercalation and surface adsorption, and evaluate potential lattice expansion without structural degradation.

“Developing a scalable, heteroatom-free, structurally optimized graphitic material and then rigorously validating its performance and mechanism posed substantial experimental and analytical hurdles,” Pramanik said.

Carbon cones and discs

Graphitic carbon is widely used as an anode material in lithium-ion batteries due to its excellent performance. However, it is unsuitable for sodium-ion batteries because of the larger size of sodium ions, which limits their ability to intercalate into the graphite structure. The team developed a novel graphitic carbon with a unique cone- or disc-shaped morphology. This specially engineered structure demonstrates remarkable performance when used as an anode in sodium-ion batteries, offering high charge storage capacity and exceptional long-term cycling stability.“Furthermore, we thoroughly investigated the sodium storage mechanism within this cone/disc graphitic carbon, revealing how its structure supports efficient sodium-ion storage,” Pramanik said. “Our findings highlight one of the most promising performances of graphitic carbon anodes for sodium-ion batteries to date.”

Discover the Benefits of ASME Membership

In the absence of heteroatoms, these graphitic carbon structures exhibit excellent Na-ion intercalation, displaying a reversible capacity of approximately 230 mAh g−1 at a current rate of 20 mA g−1 and demonstrating excellent rate performance. The electrode also exhibited outstanding performance in K-ion intercalation. Ex situ transmission electron microscopy analysis and solid-state nuclear magnetic resonance spectroscopy proved the intercalation of sodium and potassium, revealing the charge storage mechanism.

Mechanically, the robust graphitic framework exhibits minimal volume expansion, even over 2,000 cycles at high current density (10 A g⁻¹), showcasing exceptional cycling stability, which is “critical from an engineering durability standpoint,” Pramanik said. “This integration of industrial scalability, electrochemical performance, and structural stability highlights a mechanically resilient and electrochemically efficient design, pushing the frontier of graphitic materials in beyond-lithium energy storage.”

Future steps

The research team is poised to expand in several promising directions. One key next step involves further optimization of the carbon cone/disc morphology to enhance sodium and potassium ion storage performance, particularly at high current densities. In-depth mechanistic studies using advanced characterization techniques have laid the groundwork for understanding ion intercalation behavior, which can be refined further to tailor electrochemical properties.“Scaling up electrode fabrication for practical full-cell configurations, possibly with alternative cathode materials and electrolytes, will be crucial for commercial viability,” Pramanik said.

In addition, exploring electrolyte-electrode interfacial chemistry, particularly the evolution and stability of the solid electrolyte interphase during long-term cycling, will be crucial.

“This work also opens up potential for similar graphitic structures in other beyond-lithium battery systems,” Pramanik said. “Moreover, their ability to be produced from industrial waste through an environmentally benign process adds value in sustainability-driven applications across energy, environmental remediation, and even electromagnetic shielding technologies.”

Mark Crawford is a technology writer in Corrales, N.M.