Robotic Dandelion Seed Takes Flight

Robotic Dandelion Seed Takes Flight

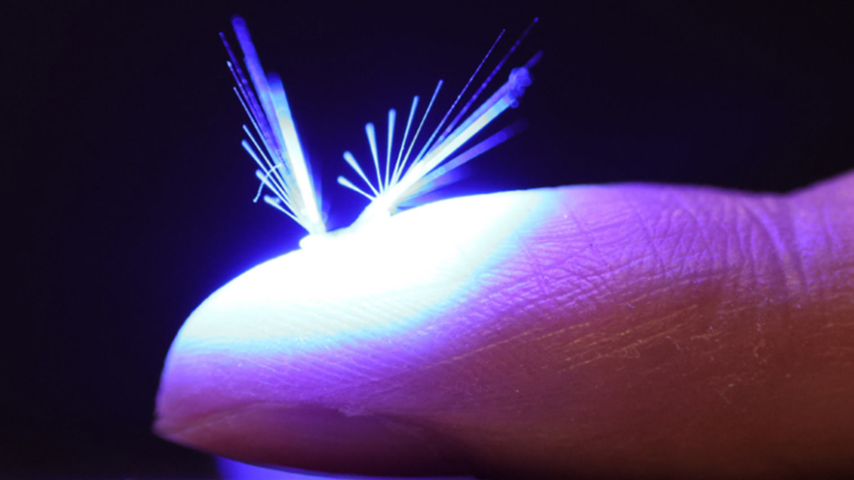

Not content to waft on the wind, the artificial seed flaps when exposed to light.

The dandelion has an effective strategy for propagation. Each seed on the fluffy white ball has a stem topped with radiating bristles called the pappus. Hit by a gust of wind, the pappus acts like a parachute, separating the seed from the rest of the plant and allowing it to travel as far as the breeze will take it. When there’s a thermal updraft, that trip can be as far as half a mile.

However impressive that might be, Taraxacum seeds would do better if they weren’t so passive. Now researchers out of Finland’s Tampere University have made the first steps toward creating robotic dandelion seeds that actively propagate themselves—the prongs of the artificial pappus open on their own, helping it to lift off in a stream of wind. The researchers plan to eventually turn this unfolding into a refolding and unfolding that becomes flapping.

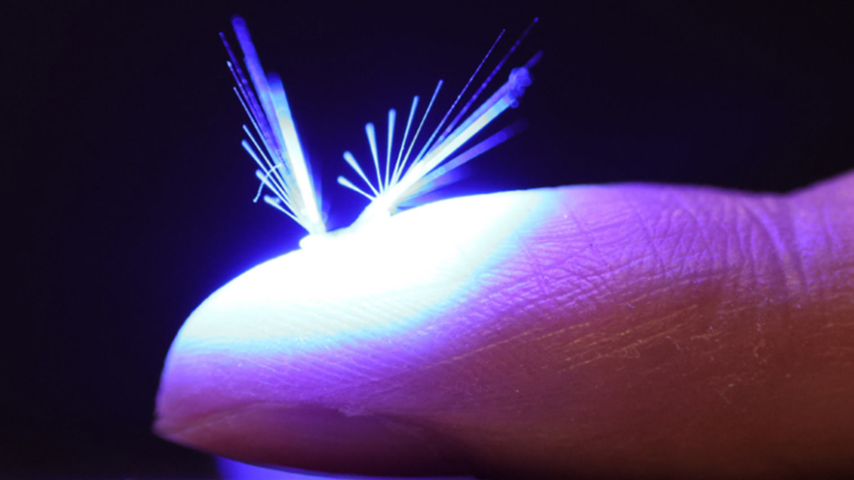

The trick to all this movement is the light-sensitive polymer the researchers used, a liquid crystal elastomer. There are thousands of different types of such elastomers.

“Each of them is a little bit different in its shape-changing sensitivities,” said Hao Zeng, a senior researcher at the university, leader of the Light Robotics group there, and co-author of the paper, “Dandelion-Inspired, Wind-Dispersed Polymer-Assembly Controlled by Light,” which appeared in Advanced Science.

Become an ASME member today

“There are many different kinds of games you can play with the materials,” Zeng said.

Other liquid crystal elastomers have already been shown to change shape when heated. Zeng and his team took things a little further and tweaked their elastomer so that it would deform rapidly when hit by light.

Of course, to flap, a material must go back and forth, not just bend in one direction. A flickering light might work on Zeng’s polymer, but he wants his dandy-bot to be able to self-oscillate and do its flying when under constant illumination. So, he and his colleagues have tweaked the architecture of their seed so it would create its own flicker.

Frontiers of Robotics: Liquifying Robot Points to Shape-Shifting Electronics

“If the light beam is coming from a horizontal direction, it bends into the shadow of itself,” Zeng said. “So then there’s no light absorption and it has to relax back. Then the material comes into the light again, so it keeps oscillating.”

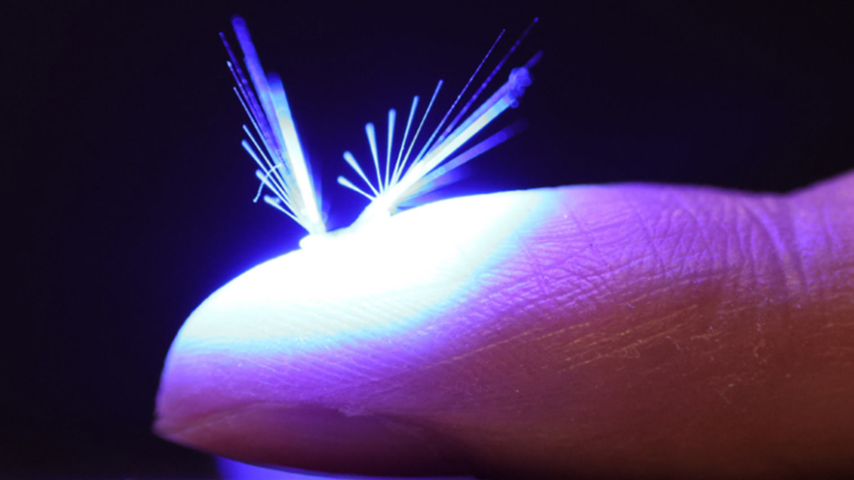

For something the size of a dandelion seed that oscillating has to be pretty fast to take off. Right now, it flaps at something like 80 times per second, faster than the wings of a butterfly (which flap at 10 hertz) and gaining on the dragonfly (which can flap at a maximum of 120 hertz). However, the motion is not sophisticated enough to make it flit about like an insect.

But this is just the beginning of the advent of robotic seeds.

“To increase the frequency is not a big issue from the material point of view,” Zeng said. “We can do some tricks, like increasing the crosslinking density, so the material will be more rigid, more like plastic. Then it’s easier to oscillate at a higher frequency.” The structure of the robot could also be reworked to make it more efficient.

Inspired by Nature: Bioinspired Medical Technologies

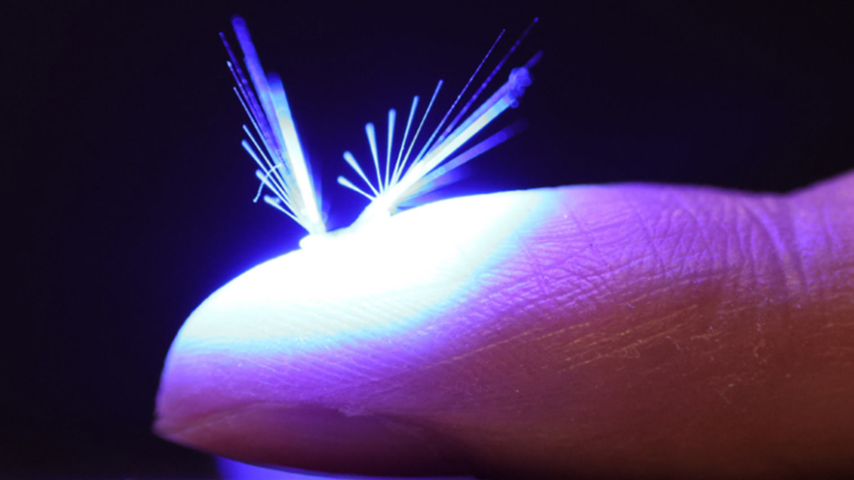

Once those efficiencies are achieved, a carefully aimed laser could introduce an element of control. Then the tiny robots could perhaps fly about helping farmers pollinate crops or environmental researchers collect data. But that doesn’t interest Zeng.

“As a basic scientist, I focus on the lessons we learn from nature,” he said. “I just want to prove the possibility of this concept—that is the most important thing for me.”

Michael Abrams is a science and technology writer in Westfield, N.J.

However impressive that might be, Taraxacum seeds would do better if they weren’t so passive. Now researchers out of Finland’s Tampere University have made the first steps toward creating robotic dandelion seeds that actively propagate themselves—the prongs of the artificial pappus open on their own, helping it to lift off in a stream of wind. The researchers plan to eventually turn this unfolding into a refolding and unfolding that becomes flapping.

The trick to all this movement is the light-sensitive polymer the researchers used, a liquid crystal elastomer. There are thousands of different types of such elastomers.

“Each of them is a little bit different in its shape-changing sensitivities,” said Hao Zeng, a senior researcher at the university, leader of the Light Robotics group there, and co-author of the paper, “Dandelion-Inspired, Wind-Dispersed Polymer-Assembly Controlled by Light,” which appeared in Advanced Science.

Become an ASME member today

“There are many different kinds of games you can play with the materials,” Zeng said.

Other liquid crystal elastomers have already been shown to change shape when heated. Zeng and his team took things a little further and tweaked their elastomer so that it would deform rapidly when hit by light.

Creating its own flicker

Of course, to flap, a material must go back and forth, not just bend in one direction. A flickering light might work on Zeng’s polymer, but he wants his dandy-bot to be able to self-oscillate and do its flying when under constant illumination. So, he and his colleagues have tweaked the architecture of their seed so it would create its own flicker.

Frontiers of Robotics: Liquifying Robot Points to Shape-Shifting Electronics

“If the light beam is coming from a horizontal direction, it bends into the shadow of itself,” Zeng said. “So then there’s no light absorption and it has to relax back. Then the material comes into the light again, so it keeps oscillating.”

For something the size of a dandelion seed that oscillating has to be pretty fast to take off. Right now, it flaps at something like 80 times per second, faster than the wings of a butterfly (which flap at 10 hertz) and gaining on the dragonfly (which can flap at a maximum of 120 hertz). However, the motion is not sophisticated enough to make it flit about like an insect.

But this is just the beginning of the advent of robotic seeds.

“To increase the frequency is not a big issue from the material point of view,” Zeng said. “We can do some tricks, like increasing the crosslinking density, so the material will be more rigid, more like plastic. Then it’s easier to oscillate at a higher frequency.” The structure of the robot could also be reworked to make it more efficient.

Inspired by Nature: Bioinspired Medical Technologies

Once those efficiencies are achieved, a carefully aimed laser could introduce an element of control. Then the tiny robots could perhaps fly about helping farmers pollinate crops or environmental researchers collect data. But that doesn’t interest Zeng.

“As a basic scientist, I focus on the lessons we learn from nature,” he said. “I just want to prove the possibility of this concept—that is the most important thing for me.”

Michael Abrams is a science and technology writer in Westfield, N.J.

.png?width=854&height=480&ext=.png)