Bioengineering Blog: Visualization of Complex Ideas in Medical Devices

Bioengineering Blog: Visualization of Complex Ideas in Medical Devices

Computational modeling coupled with visualization becomes a communication tool.

Computational modeling is first thought of as a design tool for medical device engineers, but when coupled with effective data visualization it becomes a communication tool that enhances the understanding of the effect and workings of new medical devices.

Simulation allows us to visualize things that may be abstract, difficult to understand concepts and present them in dynamic and intuitive ways to target audiences that may be unfamiliar with the device but have a need to be quickly brought up to speed and have an intuitive understanding of how it works. These target audiences cover the entire range of device development, from engineering to regulatory agencies or customers.

During the product development process teams are making design decisions and changes that need to have the justification and background communicated to other, often nontechnical, stakeholders. Simulation-based visualization helps those stakeholders understand abstract concepts like electric fields or heat transfer mechanisms, and how those physical phenomena are affected by design decisions.

Learn More About the: Top 10 Bioengineering Trends of 2020

As an example, electrosurgical devices depend on joule heating in the tissue, but the electrical impedance is changing as the tissue is heated. In turn, this impedance change modifies current distribution, which modifies the tissue heating. This dynamic response can be shown in simulations, and the dynamic change can be communicated with animations that explain how this impacts the device design.

During the regulatory process effective communication of design impacts and device mechanism of action should be clear and as streamlined as possible. In an environment where misunderstandings can translate into significant delays or outright denials it is imperative to communicate the safety and efficacy of a new medical device as clearly as possible. In this pursuit, data visualization of simulation results can help reviewers to clearly understand the medical device’s mechanism of action and how it would safely interact with varying segments of the patient population.

You May Also Like: Tools to Accelerate the Development of Energy-based Medical Devices

Understanding how the performance of a new device will change when used on an obese vs. underweight patient or on a pediatric vs. elderly patient provides confidence in device safety.

A third area where simulation-driven visualization can help medical device development is in communication with customers. Whether doctors or patients, understanding how a device works is an important part of the decision-making process when looking at treatment options.

Simulation-driven visualizations can help explain complex engineering concepts in an intuitive manner and can be presented in a limited amount of time. Taking this one step further is to incorporate an individual patient’s imaging data and then show how the device is expected to perform in that specific patient’s procedure, providing an additional layer of understanding for that doctor and patient.

Editors' Pick: Capturing Blood Cells to Isolate Tumor Cells

Computational modeling and simulation aren’t often thought of as communication tools, but when coupled with effective data visualization can become an effective way to communicate the operation of a medical device to a wide range of audiences, independent of their technical background.

Arlen Ward, PhD, PE is a Modeling and Simulation Principal for System Insight Engineering, a consultancy providing computational modeling and simulation services for medical device companies with a focus on the interaction between energy and tissue.

Opinions expressed are the author’s and do not necessarily reflect the views of ASME.

Simulation allows us to visualize things that may be abstract, difficult to understand concepts and present them in dynamic and intuitive ways to target audiences that may be unfamiliar with the device but have a need to be quickly brought up to speed and have an intuitive understanding of how it works. These target audiences cover the entire range of device development, from engineering to regulatory agencies or customers.

Product Development Communication

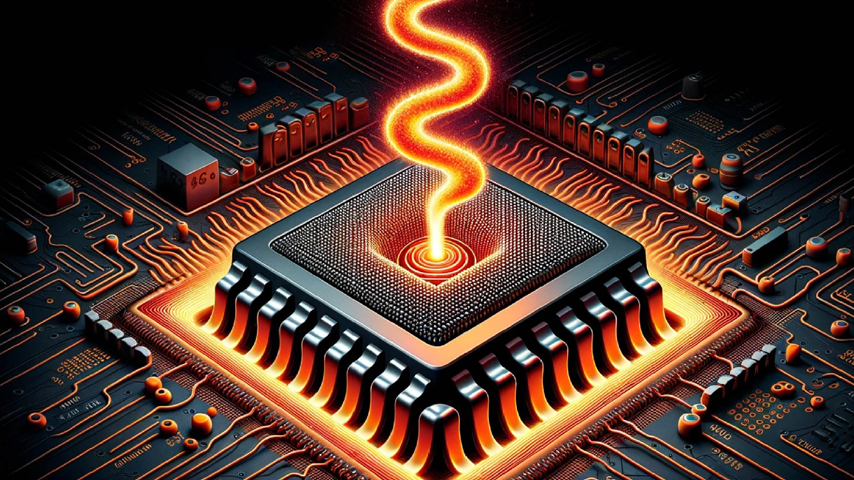

During the product development process teams are making design decisions and changes that need to have the justification and background communicated to other, often nontechnical, stakeholders. Simulation-based visualization helps those stakeholders understand abstract concepts like electric fields or heat transfer mechanisms, and how those physical phenomena are affected by design decisions.

Learn More About the: Top 10 Bioengineering Trends of 2020

As an example, electrosurgical devices depend on joule heating in the tissue, but the electrical impedance is changing as the tissue is heated. In turn, this impedance change modifies current distribution, which modifies the tissue heating. This dynamic response can be shown in simulations, and the dynamic change can be communicated with animations that explain how this impacts the device design.

Communication During Regulatory Process

During the regulatory process effective communication of design impacts and device mechanism of action should be clear and as streamlined as possible. In an environment where misunderstandings can translate into significant delays or outright denials it is imperative to communicate the safety and efficacy of a new medical device as clearly as possible. In this pursuit, data visualization of simulation results can help reviewers to clearly understand the medical device’s mechanism of action and how it would safely interact with varying segments of the patient population.

You May Also Like: Tools to Accelerate the Development of Energy-based Medical Devices

Understanding how the performance of a new device will change when used on an obese vs. underweight patient or on a pediatric vs. elderly patient provides confidence in device safety.

Communication with Customers

A third area where simulation-driven visualization can help medical device development is in communication with customers. Whether doctors or patients, understanding how a device works is an important part of the decision-making process when looking at treatment options.

Simulation-driven visualizations can help explain complex engineering concepts in an intuitive manner and can be presented in a limited amount of time. Taking this one step further is to incorporate an individual patient’s imaging data and then show how the device is expected to perform in that specific patient’s procedure, providing an additional layer of understanding for that doctor and patient.

Editors' Pick: Capturing Blood Cells to Isolate Tumor Cells

Computational modeling and simulation aren’t often thought of as communication tools, but when coupled with effective data visualization can become an effective way to communicate the operation of a medical device to a wide range of audiences, independent of their technical background.

Arlen Ward, PhD, PE is a Modeling and Simulation Principal for System Insight Engineering, a consultancy providing computational modeling and simulation services for medical device companies with a focus on the interaction between energy and tissue.

Opinions expressed are the author’s and do not necessarily reflect the views of ASME.