Why It’s Time to Embrace the Cloud in Design and Engineering

Why It’s Time to Embrace the Cloud in Design and Engineering

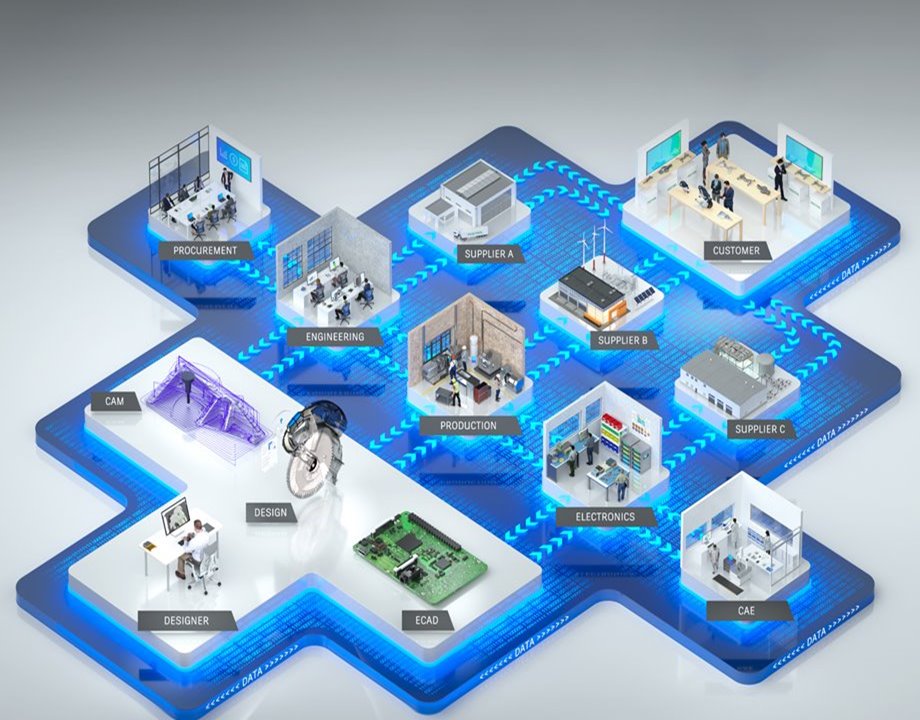

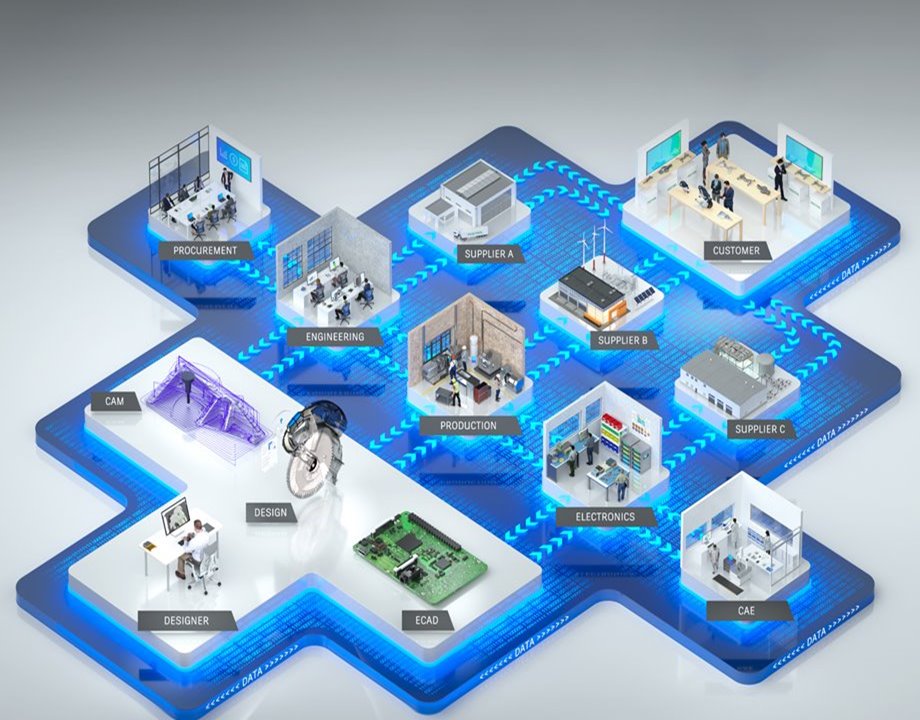

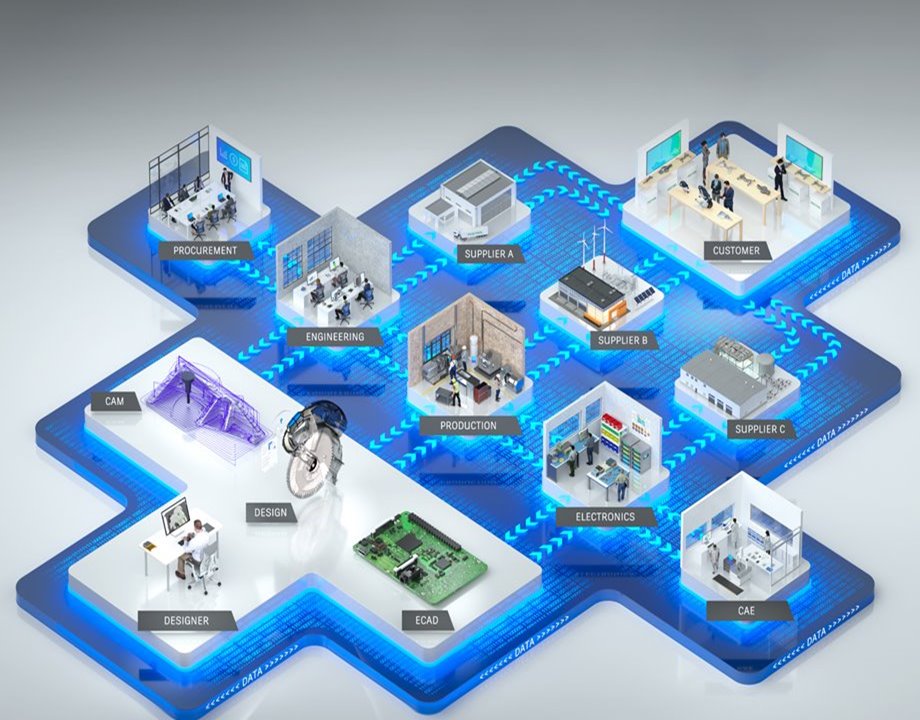

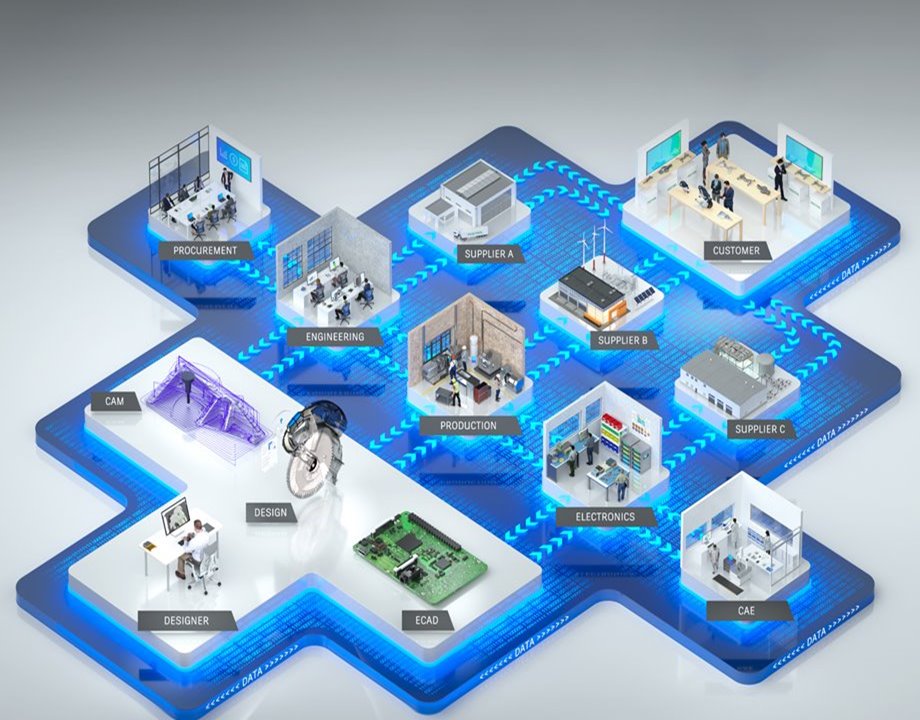

Fusion 360’s integrated platform connects data across your entire product development and manufacturing ecosystem with a cloud-based model.

The pace of change, competitive threats, and supply chain volatility present challenges now, more than ever before. But there are growth opportunities all around us, especially those in the cloud design and engineering space. Today, there are opportunities to address emerging trends such as smart devices, increase efficiency and reduce costs, and ensure flexibility and agility in the supply chain—all with cloud-based engineering.

A full 30 percent of an engineer’s time is wasted on tedious tasks like chasing down the right version of a file during the product development process. It’s messy, complicated, and limits the ability to make changes quickly in order to survive. We need a new way. Imagine a single designer or engineer in an R&D department or small business. Engineers like this wear numerous hats. That has historically meant they’d use numerous design and engineering tools.

Cloud-based engineering platforms such as Fusion 360 are revolutionizing how engineering teams imagine, collaborate, and create. These platforms give engineers the agility and connectivity to meet growing demands, the freedom to spend more time innovating rather than iterating, and the ability to improve their business and shape a thriving future.

The global pandemic has accelerated the trend for digital transformation, enabling companies to react faster and achieve even more value from product innovation. Designers and engineers need to collaborate more easily. They need to work together within their teams, across teams within a company, and across companies in their supply chain.

A cloud-based platform for design and engineering makes collaboration easy. Teams can access data from anywhere and collaborate on projects, an increasingly valuable benefit when half the business and supply chain is working remotely.

Listen to Our Podcast: The Expanding Role of Digital Engineering in Manufacturing

GoWesty, an aftermarket VW supplier based in California, has a design and engineering team that develops hundreds of new products annually. GoWesty utilized Fusion 360 as its cloud-based platform to bring design and manufacturing closer together.

By eliminating the need for multiple solutions and translating from one file format to another across the product development process, it was possible to go directly from design to manufacture. The platform can also exchange data and work seamlessly with other tools and solutions across an organization or supply chain when cross-platform compatibility is required.

“It’s really handy to be able to work on dozens and dozens of projects independently on the cloud and not have to worry as much about file organization,” said Oren Klein, a mechanical engineer at GoWesty.

Somni Solutions, a Fusion 360 user in the Netherlands, worked more quickly and efficiently on the cloud when the company needed to meet the accelerated timeline of the new Genova San Giorgio Bridge.

“One of the downsides of other modeling software is that integration onto the cloud is a very slow process, and professional licenses are extremely expensive. Fusion 360 is a whole different ballgame. The pricing is much more competitive, it’s much easier to add or get rid of an extra account, and you have the whole package, including cloud simulation, available at your command,” said Rik Knoppers, chief operating officer at Somni Solutions.

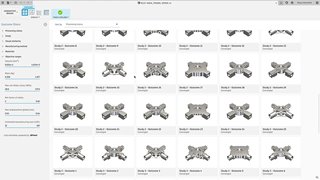

Smart decision making in today’s world of fast product development requires connecting design and manufacturing. The cloud helps from a file management standpoint–but its value does not end there. Generative design—the ability to receive design suggestions from the computer and fast-forward to identifying solutions a designer will explore more deeply—is one of the added benefits of working on a cloud-enabled platform such as Fusion 360.

Recommended for You: Digital Engineering During COVID-19

By using artificial intelligence to leverage cloud-computing power, generative design enables manufacturers to explore multiple designs in less time than they could deliver a single concept using traditional processes. This ultimately results in creating better outcomes and products.

The generative design process is completely different than the traditional process. A designer specifies the functional requirements of a product and the constraints of the manufacturing process at their disposal in order to receive generative design suggestions from the power of cloud computing that have been pre-validated for functional performance, manufacturability, and manufacturing cost.

This process dramatically reduces the need to pass designs back and forth, yielding a much shorter time to market, reduced costs, and a greater range of innovative solutions.

“Generative design really allows us to tackle complex problems that would take somebody a lot more time than they have to go through different analyses,” said John Suh, vice president of the Hyundai Motor Group. “It’s a mind multiplier, I like to call it, where a single designer or engineer can go through perhaps dozens or even hundreds of different design iterations–designs they may never have considered otherwise–in the time it would ordinarily take to create and assess two or three more familiar designs. It enables us to see new possibilities.”

Read Our Robotics Blog: Digital Twins for Robot Installations

Ultimately, generative design gives human experts the time to focus on assessing which design options best meet their requirements for all phases of product design and manufacturing, as well as aesthetics and creativity. You can get to more high-performing, cost-effective, and sustainable designs that you couldn’t have reached on your own—faster.

To find out more about how Fusion 360 can help your team achieve the new possible, visit Autodesk.

A full 30 percent of an engineer’s time is wasted on tedious tasks like chasing down the right version of a file during the product development process. It’s messy, complicated, and limits the ability to make changes quickly in order to survive. We need a new way. Imagine a single designer or engineer in an R&D department or small business. Engineers like this wear numerous hats. That has historically meant they’d use numerous design and engineering tools.

Cloud-based engineering platforms such as Fusion 360 are revolutionizing how engineering teams imagine, collaborate, and create. These platforms give engineers the agility and connectivity to meet growing demands, the freedom to spend more time innovating rather than iterating, and the ability to improve their business and shape a thriving future.

Driving Digital Transformation

The global pandemic has accelerated the trend for digital transformation, enabling companies to react faster and achieve even more value from product innovation. Designers and engineers need to collaborate more easily. They need to work together within their teams, across teams within a company, and across companies in their supply chain.

A cloud-based platform for design and engineering makes collaboration easy. Teams can access data from anywhere and collaborate on projects, an increasingly valuable benefit when half the business and supply chain is working remotely.

Listen to Our Podcast: The Expanding Role of Digital Engineering in Manufacturing

GoWesty, an aftermarket VW supplier based in California, has a design and engineering team that develops hundreds of new products annually. GoWesty utilized Fusion 360 as its cloud-based platform to bring design and manufacturing closer together.

By eliminating the need for multiple solutions and translating from one file format to another across the product development process, it was possible to go directly from design to manufacture. The platform can also exchange data and work seamlessly with other tools and solutions across an organization or supply chain when cross-platform compatibility is required.

“It’s really handy to be able to work on dozens and dozens of projects independently on the cloud and not have to worry as much about file organization,” said Oren Klein, a mechanical engineer at GoWesty.

Somni Solutions, a Fusion 360 user in the Netherlands, worked more quickly and efficiently on the cloud when the company needed to meet the accelerated timeline of the new Genova San Giorgio Bridge.

“One of the downsides of other modeling software is that integration onto the cloud is a very slow process, and professional licenses are extremely expensive. Fusion 360 is a whole different ballgame. The pricing is much more competitive, it’s much easier to add or get rid of an extra account, and you have the whole package, including cloud simulation, available at your command,” said Rik Knoppers, chief operating officer at Somni Solutions.

Intelligently Power Your Decision-Making

Smart decision making in today’s world of fast product development requires connecting design and manufacturing. The cloud helps from a file management standpoint–but its value does not end there. Generative design—the ability to receive design suggestions from the computer and fast-forward to identifying solutions a designer will explore more deeply—is one of the added benefits of working on a cloud-enabled platform such as Fusion 360.

Recommended for You: Digital Engineering During COVID-19

By using artificial intelligence to leverage cloud-computing power, generative design enables manufacturers to explore multiple designs in less time than they could deliver a single concept using traditional processes. This ultimately results in creating better outcomes and products.

The generative design process is completely different than the traditional process. A designer specifies the functional requirements of a product and the constraints of the manufacturing process at their disposal in order to receive generative design suggestions from the power of cloud computing that have been pre-validated for functional performance, manufacturability, and manufacturing cost.

This process dramatically reduces the need to pass designs back and forth, yielding a much shorter time to market, reduced costs, and a greater range of innovative solutions.

“Generative design really allows us to tackle complex problems that would take somebody a lot more time than they have to go through different analyses,” said John Suh, vice president of the Hyundai Motor Group. “It’s a mind multiplier, I like to call it, where a single designer or engineer can go through perhaps dozens or even hundreds of different design iterations–designs they may never have considered otherwise–in the time it would ordinarily take to create and assess two or three more familiar designs. It enables us to see new possibilities.”

Read Our Robotics Blog: Digital Twins for Robot Installations

Ultimately, generative design gives human experts the time to focus on assessing which design options best meet their requirements for all phases of product design and manufacturing, as well as aesthetics and creativity. You can get to more high-performing, cost-effective, and sustainable designs that you couldn’t have reached on your own—faster.

To find out more about how Fusion 360 can help your team achieve the new possible, visit Autodesk.

.png?width=854&height=480&ext=.png)