Virus Killer

Virus Killer

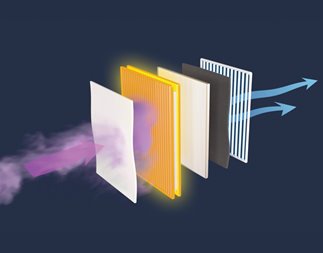

This year’s Emerging Technology Awards celebrates Medistar Corp.’s COVID-19 killing HVAC filter. Illustration: Richard Borge

COVID-19 has produced many more questions than answers. Among the most pertinent are exactly how it is dispersed and how long the virus stays active. A recent study published in the journal Emerging Infectious Diseases showed the virus dispersed through the air remains infectious for up to 16 hours. Such findings emphasize the need for indoor air protection, one that may be met by a novel new indoor air filter.

A new HVAC filter developed through a collaboration of Houston-based medical real estate developer Medistar and researchers at the University of Houston and Texas A&M University uses a heated filter made of nickel foam that traps and kills 99.8 percent of the virus. The results were detailed in Materials Today Physics, from testing conducted at the Texas Center for Superconductivity at the University of Houston and Galveston National Laboratory.

Editor's Pick: Video: 2020 Emerging Technology Awards

Medistar CEO Monzer Hourani, an engineer and inventor, led development of the patent-pending technology, now being sold through Medistar subsidiary Integrated Viral Protection. The filters are already being used in a Texas school district, the Houston Convention Center and the Houston Intercontinental Hotel.

The filter is based on HEPA-filter technology but differs in that it kills the virus, not simply trapping it. That also makes for safer disposal, according to Zhifeng Ren, co-lead investigator and director of the Texas superconductivity center. The filter is encased in a fire-retardant frame, and uses UV-C light to catch and kill spores as small as 100 nanometers and up to 1,000 nanometers. The virus cannot survive temperatures above 70 degrees Centigrade. While the filter is heated to high temperatures, there is not any significant heating of ambient air.

“This novel biodefense indoor air-conditioning technology…offers the first in-line prevention against environmentally mediated transmission of airborne SARS-COV-2 and will be in the forefront of technologies available to combat the current COVID-19 pandemic and future airborne biothreats indoors,” said Dr. Faisal Cheema, associate professor of biomedical and clinical sciences at the University of Houston College of Medicine.

The filter also has shown to destroy anthrax spores at 99.9 percent efficiency and may be capable of the same with Legionnaire’s Disease. Researchers did not test specifically for the bacteria that causes Legionnaire’s Disease, legionella, but believe its 99.9 percent effectiveness against anthrax would likely also destroy the bacteria.

Reader's Choice: Engineers in Action During COVID-19

The filter is a simple plug-and-play installation for residential and commercial buildings, according to the firm. Standalone units of various sizes fit most HVAC systems, and the biodefense filter does not impact air flow or produce ozone. The U.S. Food and Drug Administration has permitted sales.

According to Hourani, “The school unit is capable of powerfully recirculating air ten times an hour at 1,800 cubic feet per minute for a standard-sized classroom (30 ft x 30 ft x 15 ft), exceeding the re-opening guidelines issued by the American Society of Heating, Refrigerating and Air-Conditioning Engineers. Let us engineer our way out off this crisis.”

The filters are being manufactured through a partnership with IVP and three manufacturing companies in the U.S., Canada, and Mexico: Dust Free LP; Engineering CPR, and Instalaciones y Especialidades Metalicas SA de CV.

John Kosowatz is senior editor.

See who the other winners are in Video: 2020 Emerging Technology Awards

A new HVAC filter developed through a collaboration of Houston-based medical real estate developer Medistar and researchers at the University of Houston and Texas A&M University uses a heated filter made of nickel foam that traps and kills 99.8 percent of the virus. The results were detailed in Materials Today Physics, from testing conducted at the Texas Center for Superconductivity at the University of Houston and Galveston National Laboratory.

Editor's Pick: Video: 2020 Emerging Technology Awards

Medistar CEO Monzer Hourani, an engineer and inventor, led development of the patent-pending technology, now being sold through Medistar subsidiary Integrated Viral Protection. The filters are already being used in a Texas school district, the Houston Convention Center and the Houston Intercontinental Hotel.

The filter is based on HEPA-filter technology but differs in that it kills the virus, not simply trapping it. That also makes for safer disposal, according to Zhifeng Ren, co-lead investigator and director of the Texas superconductivity center. The filter is encased in a fire-retardant frame, and uses UV-C light to catch and kill spores as small as 100 nanometers and up to 1,000 nanometers. The virus cannot survive temperatures above 70 degrees Centigrade. While the filter is heated to high temperatures, there is not any significant heating of ambient air.

“This novel biodefense indoor air-conditioning technology…offers the first in-line prevention against environmentally mediated transmission of airborne SARS-COV-2 and will be in the forefront of technologies available to combat the current COVID-19 pandemic and future airborne biothreats indoors,” said Dr. Faisal Cheema, associate professor of biomedical and clinical sciences at the University of Houston College of Medicine.

The filter also has shown to destroy anthrax spores at 99.9 percent efficiency and may be capable of the same with Legionnaire’s Disease. Researchers did not test specifically for the bacteria that causes Legionnaire’s Disease, legionella, but believe its 99.9 percent effectiveness against anthrax would likely also destroy the bacteria.

Reader's Choice: Engineers in Action During COVID-19

The filter is a simple plug-and-play installation for residential and commercial buildings, according to the firm. Standalone units of various sizes fit most HVAC systems, and the biodefense filter does not impact air flow or produce ozone. The U.S. Food and Drug Administration has permitted sales.

According to Hourani, “The school unit is capable of powerfully recirculating air ten times an hour at 1,800 cubic feet per minute for a standard-sized classroom (30 ft x 30 ft x 15 ft), exceeding the re-opening guidelines issued by the American Society of Heating, Refrigerating and Air-Conditioning Engineers. Let us engineer our way out off this crisis.”

The filters are being manufactured through a partnership with IVP and three manufacturing companies in the U.S., Canada, and Mexico: Dust Free LP; Engineering CPR, and Instalaciones y Especialidades Metalicas SA de CV.

John Kosowatz is senior editor.

See who the other winners are in Video: 2020 Emerging Technology Awards

.png?width=854&height=480&ext=.png)