NASA Plans to Retrace Apollo’s Footsteps

NASA Plans to Retrace Apollo’s Footsteps

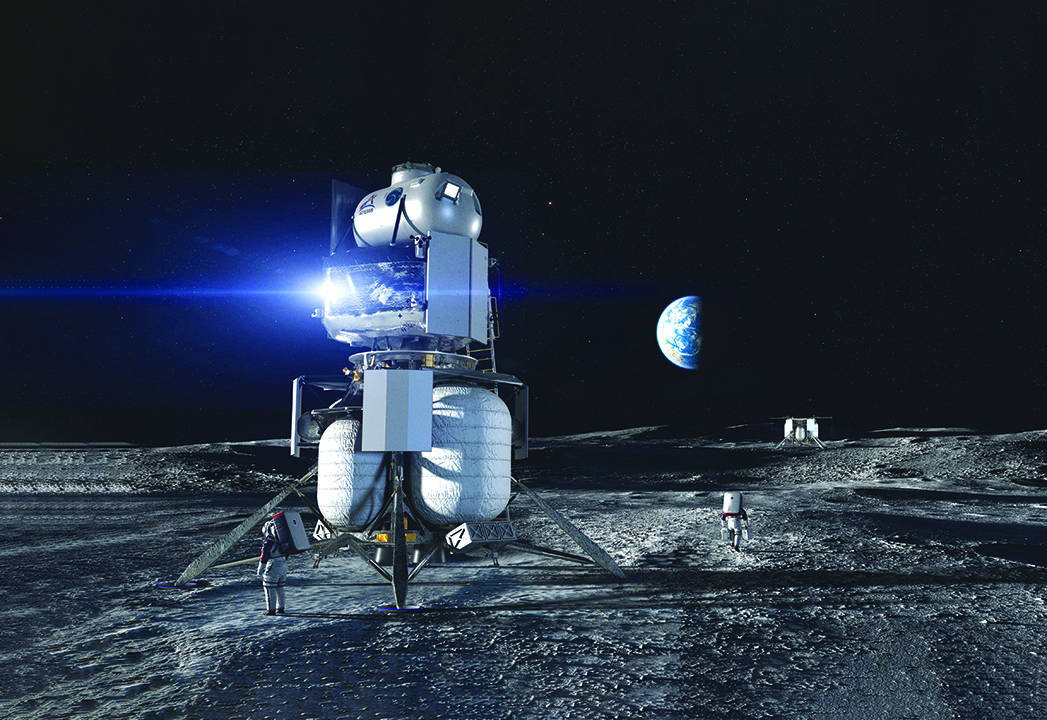

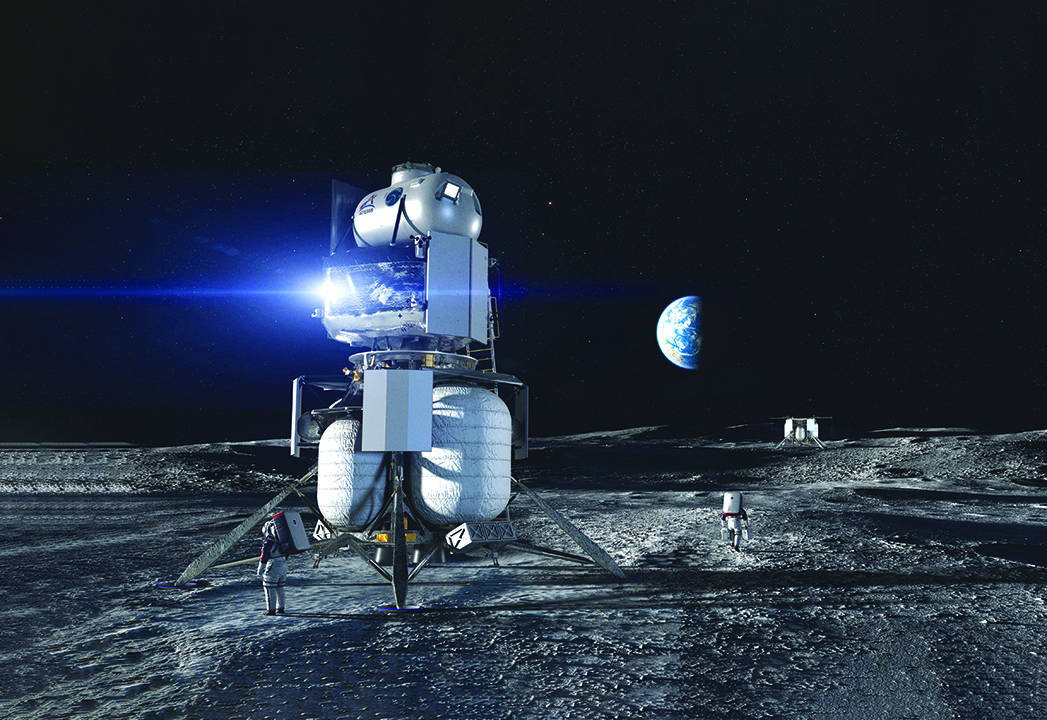

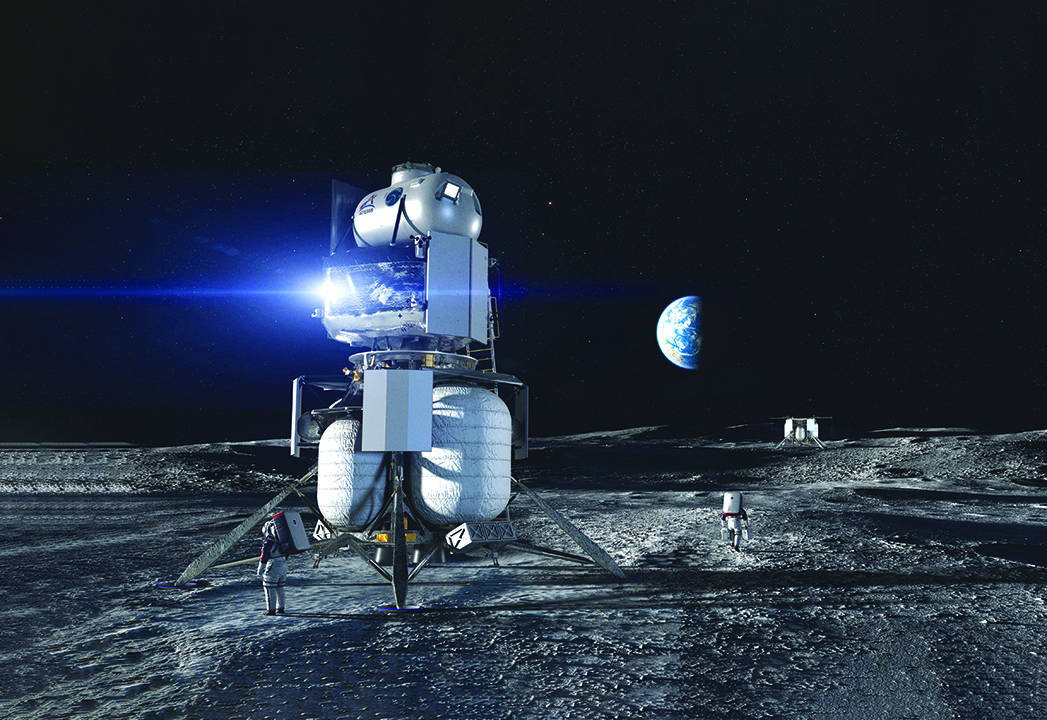

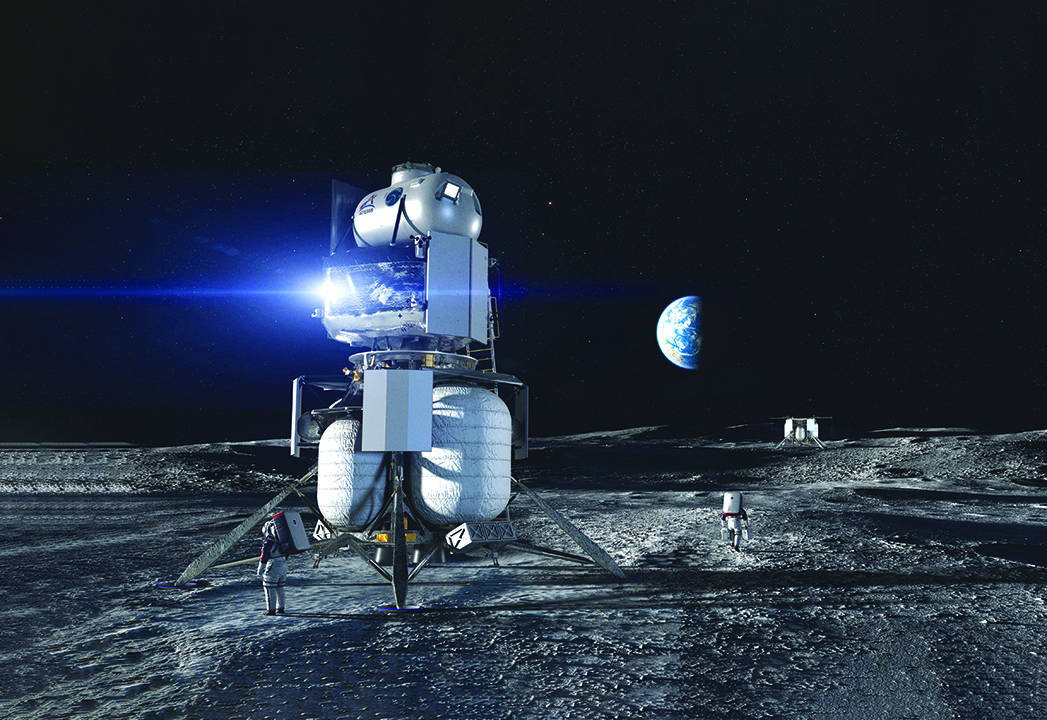

The Moon landings were a watershed moment for humanity. NASA’s new Artemis program to return astronauts to the lunar surface could well be a steppingstone to the cosmos. Image: Blue Origin

The plaque left on the Sea of Tranquility by Neil Armstrong and Buzz Aldrin bore a simple message: “We came in peace for all Mankind.” But the Moon Race was part of a contest between nations and ideological systems and commanded military-scale budgets from both the United States and the Soviet Union.

Today, more than 50 years after the Apollo 11 Moon landing (and nearly 30 since the end of the USSR), NASA is engaged in a new program to send astronauts back to the lunar surface. It ought to be a cinch, as our computers, design tools, and materials are radically more advanced than they were for the first trips to the Moon. But the demands of space travel haven’t changed at all—it is still a difficult and dangerous business—and dictate the shape of space exploration more than our high-tech gadgetry. Indeed, some elements of the new program, called Artemis, will seem like carbon copies of the 1960s roadmap to the Moon.

The first step—which could happen as early as this November—will be to launch an unmanned crew capsule to lunar orbit, dipping to within 62 miles of the surface before returning to Earth and splashing down in the Pacific. Step two is the same as the first, but with the capsule carrying four astronauts; much like the famed Apollo 8 mission on Christmas 1968, the astronauts will get a closeup view of the lunar surface but won’t set foot on it.

The third step was intended to be different from anything that has been tried before. Unlike the Apollo missions which launched every piece of equipment all at once, the plan was for the Artemis crew to dock with and an orbiting waystation. The astronauts would hang out for a few orbits and then descend to the surface via a lander that had been prepositioned at the station. NASA has described the Lunar Gateway station as a means to make Moon missions more sustainable, since equipment that shuttled between orbit and the surface could be reused multiple times. It could even serve as a base camp for missions to Mars or near-Earth asteroids.

More Like This: How Engineers Put Astronauts on the Moon

That plan was revised last year: To meet a stepped-up deadline of reaching the Moon by 2024, the first landing leapfrogged the building of the Lunar Gateway and will send everything to the surface in one fell swoop.

One other, major difference between Apollo and Artemis highlights the difference between the Cold War and today. In the 1960s, many of NASA’s main contractors, such as Grumman and North American Rockwell, built military aircraft. For Artemis, NASA is working with space-only companies such as Blue Origin and SpaceX. The new race to the Moon may be more leisurely than the first, but if all goes well, it will not plant the American flag on the lunar surface but modern American capitalism.

In Greek mythology, Artemis was the twin sister of Apollo. It is fitting, then, that elements of the Artemis program share some DNA with its predecessor. Take the new crew capsule, called Orion.

“The spacecraft looks similar from the outside,” said Carlos Garcia-Galan, Orion’s technical manager at NASA, “but from an engineering perspective, it has many elements that are drastically different.”

By adopting the same gumdrop shape, the engineering team could borrow from the voluminous knowledge that NASA had gleaned from previous lunar visits while adding today’s analytical and modelling tools. “The Apollo pod people were pretty smart folks and they had solved a lot of problems,” said Larry Price, Lockheed Martin’s deputy program manager for Orion.

But for all the button-downed competence we now associate with the Apollo program, Price said that his team discovered some design decisions flirted with disaster. “We learned things were a little closer to the edge than we thought before.”

ASME Video: Engineering Apollo 11: The Lunar Program

One of those edges was the heat shield. To protect the spacecraft on re-entry, a fiberglass honeycomb was bonded to its skin. Apollo technicians filled each honeycomb cell with epoxy phenol formaldehyde resin called AVCOAT and let it sit. The material didn’t always cure the way it was supposed to. “You couldn’t get temperature constancy through the cure process,” Price said. Workers would have to drill out faulty sections and refill them. Evidence of that work is on display at the Smithsonian Air and Space Museum where the heat shield on the Apollo 11 Command Module is pocked with one-inch diameter circles.

To get more a more predictable result, Orion engineers switched to smaller blocks of AVCOAT-impregnated honeycombs, which also have the advantage of being cheaper to produce. In July 2020, NASA technicians finished gluing 180 such blocks of to the capsule’s concave surface.

“Like every engineering solution, when you solve one problem you create another,” Price said. Gaps between blocks also had to be filled. But then the behavior and performance of the gap filler had to be tested and understood. “When it erodes it changes the surface, the surface changes the local aerodynamics, the local aerodynamics changes the heating, which then changes the erosion,” Price continued. “While we tried to solve the problem that Apollo had in manufacturing, we created a challenge in engineering to show what the tolerance was.”

Re-entry isn’t the only high-energy event Orion engineers have to plan for. While the Apollo missions managed to carry its living cargo through the Van Allen belts and back with minimal radiation exposure, that success was largely a matter of luck—no solar event sent a mission-spoiling dose their way.

“We have to account for solar storms,” Garcia-Galan said. “We took a survey of solar storms over the last 50 years, took the worst radiation levels from the worst storm and said ‘We need to be able to sustain an event like that.’ ” The Orion capsule has storage compartments that can be emptied and used as a temporary refuge in the case a radiation event.

Engineering of the Apollo Program: The Greatest Engineering Adventure Ever Taken

Needless to say, Orion’s engineers have scoured the vehicle looking for ways to minimize weight. That means using the lightest materials, schemes to keep wiring as short as possible, and jettisoning anything remotely superfluous. “I’m an engineer: I want the Cadillac version in everything we do,” Garcia-Galan said, “but we have to fight that urge, or you end up working it to a point where it can never fly.”

For all that effort, Orion will in no way be lighter than its predecessor. The Apollo command module weighed 12,251 pounds, while the crew module for Artemis comes in at 21,900. Still, that is quite an achievement for a four-person spacecraft designed to be robust enough to be reused. The plan is to send up a crew once a year with one of four Orion capsules while engineers and technicians refurbish the other three.

When the Lunar Modules touched down on the Moon’s surface, they were met by a dusty emptiness. The plan for the Artemis astronauts to have resources waiting for them—kind of like FedExing your luggage to a hotel before you get on the plane. But to absolutely, positively get the equipment to the Moon, the logistics company of choice may well be Astrobotic. The Pittsburgh-based space robotics company is scheduled to deliver 28 payloads (including a microprint edition of Wikipedia) to the flat Lacus Mortis via its Peregrine lander later this year. The company also has a contract to land a NASA rover in 2023.

“We are building a lunar delivery service,” said CEO John Thornton.

Much of Astrobotic’s design for the Peregrine—foil-sided chassis and spidery legs—recalls the Apollo-era Lunar Modules. Even the testing regime was identical: When Astrobotic engineers wanted to learn how to test a lander’s ability to stay upright on landing, they looked to 1960s NASA procedures. “They tilted the lander on its side, built a cart, and pushed it into a wall to see if it tips over,” said Pete Frye, Astrobotic’s mechanical systems manager. Frye and his team followed suit.

If the design isn’t particularly innovative, the business plan is. Instead of building to NASA’s order, the company sees its landing system as a service for hire. “For something like the Moon, where the goal is to go regularly—that’s the tipping point for commercial,” Thornton said. “Flying again and again, you get affordability, reliability and frequency up, so it drives a different outcome. Instead of maximizing performance or science, you create something that is more commercial.”

More on this Topic: Engineering the Apollo 11 Lunar Module

Astrobotic sees itself not as a delivery company, but as a logistics provider for organizations looking to send payloads to the Moon. The company will offer power, communications relays, visual verification of payloads deploying, rovers—even wi-fi on the surface. “The launch vehicle helps push us into the right trajectory and then we separate pretty close to Earth and take over from there,” said Daniel Gillies, a mission director at the company.

Commercialization is a two-way flight path. Rather than having to build a unique rocket for a specific mission, Astrobotic has a choice of rockets from different companies that it can pick and choose from. There was no such market for Apollo’s mission planners. But for Artemis, NASA went shopping for the best deals. Just as Astrobotic will be delivering cargo to the lunar surface and Lockheed Martin will be building Orion, Colorado’s Maxar Technologies will be responsible for the power and propulsion element on the Lunar Gateway, and Blue Origin is leading the development of the lander. Even old-school aerospace contractor Northrup Grumman is part of the program, assembling the Habitation and Logistics Outpost portion of the Gateway.

“When I started at NASA there was no commercial concept at the time,” said William “Rod” Jones, manager of the Gateway Vehicle Systems Integration Office for NASA. “Now we are doing everything we can to leverage existing commercial product lines in order to buy down the cost of exploration.”

Editor's Choice: Commercial Crew: The Return of Manned Missions

Whether Artemis ends up being a steppingstone to Mars remains to be seen. But it is almost inevitable that it will be the catalyst for a new era of space commercialization—private prospecting missions, “moon-tested” products, maybe even lunar advertising. If Apollo was “a small step for a man,” Artemis may well be a giant leap for extraterrestrial capitalism.

The Apollo Moon landings were virtually touch-and-go missions lasting as little as one day on the surface. The Lunar Gateway is designed to serve as a base camp for longer expeditions. “The individuals who did things like go to mount Everest, or go to the North or South Poles—they went there very lean and very quickly,” said William “Rod” Jones, manager of the Gateway Vehicle Systems Integration Office for NASA. “They didn’t have an infrastructure to support them along the way. Now we have base camps and stations.”

The Lunar Gateway borrows much of its architecture from the International Space Station but pared down and simplified. Instead of ISS’s ungainly agglomeration of modules, the Gateway is essentially two cans: The Habitation and Logistics Outpost, where astronauts will spend their time, and a 60-kilowatt Power and Propulsion Element.

The Gateway’s loopy, seven-day orbit will range out as far as 70,000 km above the lunar south pole power swooping in to within 3,000 km as it passes over the lunar north pole. “We could go lower,” Jones said, “but we picked that as a really good altitude for nominal operations. When you get close to a large body like the moon, your vehicle starts to have different heating and cooling characteristics.”

Initially dreamt up when NASA’s eyes were for Mars only, the Gateway can still serve as a staging area for manned voyages farther out in the solar system. “Gateway is an aggregation point in cislunar space,” Jones said. “It’s away from the Earth’s gravity, far enough away that we can get to it and then operate from there more freely and assemble larger vehicles.”

Michael Abrams is a freelance science and technology writer based in Westfield, N.J.

Today, more than 50 years after the Apollo 11 Moon landing (and nearly 30 since the end of the USSR), NASA is engaged in a new program to send astronauts back to the lunar surface. It ought to be a cinch, as our computers, design tools, and materials are radically more advanced than they were for the first trips to the Moon. But the demands of space travel haven’t changed at all—it is still a difficult and dangerous business—and dictate the shape of space exploration more than our high-tech gadgetry. Indeed, some elements of the new program, called Artemis, will seem like carbon copies of the 1960s roadmap to the Moon.

The first step—which could happen as early as this November—will be to launch an unmanned crew capsule to lunar orbit, dipping to within 62 miles of the surface before returning to Earth and splashing down in the Pacific. Step two is the same as the first, but with the capsule carrying four astronauts; much like the famed Apollo 8 mission on Christmas 1968, the astronauts will get a closeup view of the lunar surface but won’t set foot on it.

The third step was intended to be different from anything that has been tried before. Unlike the Apollo missions which launched every piece of equipment all at once, the plan was for the Artemis crew to dock with and an orbiting waystation. The astronauts would hang out for a few orbits and then descend to the surface via a lander that had been prepositioned at the station. NASA has described the Lunar Gateway station as a means to make Moon missions more sustainable, since equipment that shuttled between orbit and the surface could be reused multiple times. It could even serve as a base camp for missions to Mars or near-Earth asteroids.

More Like This: How Engineers Put Astronauts on the Moon

That plan was revised last year: To meet a stepped-up deadline of reaching the Moon by 2024, the first landing leapfrogged the building of the Lunar Gateway and will send everything to the surface in one fell swoop.

One other, major difference between Apollo and Artemis highlights the difference between the Cold War and today. In the 1960s, many of NASA’s main contractors, such as Grumman and North American Rockwell, built military aircraft. For Artemis, NASA is working with space-only companies such as Blue Origin and SpaceX. The new race to the Moon may be more leisurely than the first, but if all goes well, it will not plant the American flag on the lunar surface but modern American capitalism.

Re-Engineering Re-Entry

In Greek mythology, Artemis was the twin sister of Apollo. It is fitting, then, that elements of the Artemis program share some DNA with its predecessor. Take the new crew capsule, called Orion.

“The spacecraft looks similar from the outside,” said Carlos Garcia-Galan, Orion’s technical manager at NASA, “but from an engineering perspective, it has many elements that are drastically different.”

By adopting the same gumdrop shape, the engineering team could borrow from the voluminous knowledge that NASA had gleaned from previous lunar visits while adding today’s analytical and modelling tools. “The Apollo pod people were pretty smart folks and they had solved a lot of problems,” said Larry Price, Lockheed Martin’s deputy program manager for Orion.

But for all the button-downed competence we now associate with the Apollo program, Price said that his team discovered some design decisions flirted with disaster. “We learned things were a little closer to the edge than we thought before.”

ASME Video: Engineering Apollo 11: The Lunar Program

One of those edges was the heat shield. To protect the spacecraft on re-entry, a fiberglass honeycomb was bonded to its skin. Apollo technicians filled each honeycomb cell with epoxy phenol formaldehyde resin called AVCOAT and let it sit. The material didn’t always cure the way it was supposed to. “You couldn’t get temperature constancy through the cure process,” Price said. Workers would have to drill out faulty sections and refill them. Evidence of that work is on display at the Smithsonian Air and Space Museum where the heat shield on the Apollo 11 Command Module is pocked with one-inch diameter circles.

To get more a more predictable result, Orion engineers switched to smaller blocks of AVCOAT-impregnated honeycombs, which also have the advantage of being cheaper to produce. In July 2020, NASA technicians finished gluing 180 such blocks of to the capsule’s concave surface.

“Like every engineering solution, when you solve one problem you create another,” Price said. Gaps between blocks also had to be filled. But then the behavior and performance of the gap filler had to be tested and understood. “When it erodes it changes the surface, the surface changes the local aerodynamics, the local aerodynamics changes the heating, which then changes the erosion,” Price continued. “While we tried to solve the problem that Apollo had in manufacturing, we created a challenge in engineering to show what the tolerance was.”

Re-entry isn’t the only high-energy event Orion engineers have to plan for. While the Apollo missions managed to carry its living cargo through the Van Allen belts and back with minimal radiation exposure, that success was largely a matter of luck—no solar event sent a mission-spoiling dose their way.

“We have to account for solar storms,” Garcia-Galan said. “We took a survey of solar storms over the last 50 years, took the worst radiation levels from the worst storm and said ‘We need to be able to sustain an event like that.’ ” The Orion capsule has storage compartments that can be emptied and used as a temporary refuge in the case a radiation event.

Engineering of the Apollo Program: The Greatest Engineering Adventure Ever Taken

Needless to say, Orion’s engineers have scoured the vehicle looking for ways to minimize weight. That means using the lightest materials, schemes to keep wiring as short as possible, and jettisoning anything remotely superfluous. “I’m an engineer: I want the Cadillac version in everything we do,” Garcia-Galan said, “but we have to fight that urge, or you end up working it to a point where it can never fly.”

For all that effort, Orion will in no way be lighter than its predecessor. The Apollo command module weighed 12,251 pounds, while the crew module for Artemis comes in at 21,900. Still, that is quite an achievement for a four-person spacecraft designed to be robust enough to be reused. The plan is to send up a crew once a year with one of four Orion capsules while engineers and technicians refurbish the other three.

Lunar Logistics

When the Lunar Modules touched down on the Moon’s surface, they were met by a dusty emptiness. The plan for the Artemis astronauts to have resources waiting for them—kind of like FedExing your luggage to a hotel before you get on the plane. But to absolutely, positively get the equipment to the Moon, the logistics company of choice may well be Astrobotic. The Pittsburgh-based space robotics company is scheduled to deliver 28 payloads (including a microprint edition of Wikipedia) to the flat Lacus Mortis via its Peregrine lander later this year. The company also has a contract to land a NASA rover in 2023.

“We are building a lunar delivery service,” said CEO John Thornton.

Much of Astrobotic’s design for the Peregrine—foil-sided chassis and spidery legs—recalls the Apollo-era Lunar Modules. Even the testing regime was identical: When Astrobotic engineers wanted to learn how to test a lander’s ability to stay upright on landing, they looked to 1960s NASA procedures. “They tilted the lander on its side, built a cart, and pushed it into a wall to see if it tips over,” said Pete Frye, Astrobotic’s mechanical systems manager. Frye and his team followed suit.

If the design isn’t particularly innovative, the business plan is. Instead of building to NASA’s order, the company sees its landing system as a service for hire. “For something like the Moon, where the goal is to go regularly—that’s the tipping point for commercial,” Thornton said. “Flying again and again, you get affordability, reliability and frequency up, so it drives a different outcome. Instead of maximizing performance or science, you create something that is more commercial.”

More on this Topic: Engineering the Apollo 11 Lunar Module

Astrobotic sees itself not as a delivery company, but as a logistics provider for organizations looking to send payloads to the Moon. The company will offer power, communications relays, visual verification of payloads deploying, rovers—even wi-fi on the surface. “The launch vehicle helps push us into the right trajectory and then we separate pretty close to Earth and take over from there,” said Daniel Gillies, a mission director at the company.

Commercialization is a two-way flight path. Rather than having to build a unique rocket for a specific mission, Astrobotic has a choice of rockets from different companies that it can pick and choose from. There was no such market for Apollo’s mission planners. But for Artemis, NASA went shopping for the best deals. Just as Astrobotic will be delivering cargo to the lunar surface and Lockheed Martin will be building Orion, Colorado’s Maxar Technologies will be responsible for the power and propulsion element on the Lunar Gateway, and Blue Origin is leading the development of the lander. Even old-school aerospace contractor Northrup Grumman is part of the program, assembling the Habitation and Logistics Outpost portion of the Gateway.

“When I started at NASA there was no commercial concept at the time,” said William “Rod” Jones, manager of the Gateway Vehicle Systems Integration Office for NASA. “Now we are doing everything we can to leverage existing commercial product lines in order to buy down the cost of exploration.”

Editor's Choice: Commercial Crew: The Return of Manned Missions

Whether Artemis ends up being a steppingstone to Mars remains to be seen. But it is almost inevitable that it will be the catalyst for a new era of space commercialization—private prospecting missions, “moon-tested” products, maybe even lunar advertising. If Apollo was “a small step for a man,” Artemis may well be a giant leap for extraterrestrial capitalism.

Base Camp in Lunar Orbit

The Apollo Moon landings were virtually touch-and-go missions lasting as little as one day on the surface. The Lunar Gateway is designed to serve as a base camp for longer expeditions. “The individuals who did things like go to mount Everest, or go to the North or South Poles—they went there very lean and very quickly,” said William “Rod” Jones, manager of the Gateway Vehicle Systems Integration Office for NASA. “They didn’t have an infrastructure to support them along the way. Now we have base camps and stations.”

The Lunar Gateway borrows much of its architecture from the International Space Station but pared down and simplified. Instead of ISS’s ungainly agglomeration of modules, the Gateway is essentially two cans: The Habitation and Logistics Outpost, where astronauts will spend their time, and a 60-kilowatt Power and Propulsion Element.

The Gateway’s loopy, seven-day orbit will range out as far as 70,000 km above the lunar south pole power swooping in to within 3,000 km as it passes over the lunar north pole. “We could go lower,” Jones said, “but we picked that as a really good altitude for nominal operations. When you get close to a large body like the moon, your vehicle starts to have different heating and cooling characteristics.”

Initially dreamt up when NASA’s eyes were for Mars only, the Gateway can still serve as a staging area for manned voyages farther out in the solar system. “Gateway is an aggregation point in cislunar space,” Jones said. “It’s away from the Earth’s gravity, far enough away that we can get to it and then operate from there more freely and assemble larger vehicles.”

Michael Abrams is a freelance science and technology writer based in Westfield, N.J.