Mechanics Move into the Visual Space Through Structural Color

Mechanics Move into the Visual Space Through Structural Color

Massachusetts Institute of Technology’s school of mechanical engineering is part of a broader, global group of students, researchers, and engineers exploring the possibilities of structural color.

The interplay of light through structure creates some of the most brilliant colors found in nature. Imagine iridescent butterfly wings, an opal, or the colors reflected when oil meets a water droplet.

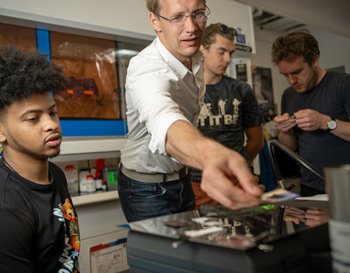

That natural creation of color crafted from the bending of light through nanostructures, rather than pigments or dyes, inspires Associate Professor Mathias Kolle’s work. He and his graduate students within Massachusetts Institute of Technology’s (MIT) School of Mechanical Engineering are part of a broader, global group of students, researchers, and engineers exploring the process and possibilities of structural color.

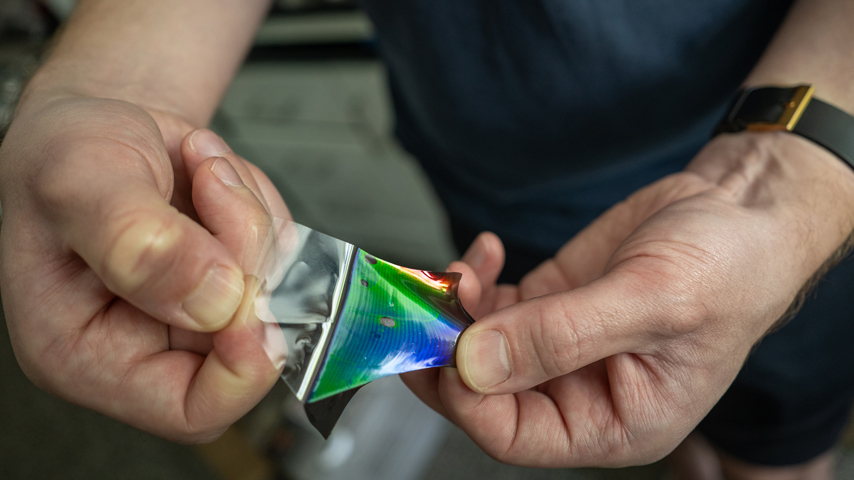

Their research on how light waves reflect through microscopic geometries translates mechanics into optical cues. Though too small to see with the naked eye, nano- or micro-structures can manipulate waves of light for dynamic visual results. The study of structural color presents opportunities to “push the capacity that materials have to change optics,” Kolle said.

“If we can control the color, then we can control the appearance,” he said. “You can translate mechanical cues, shape and form into optical cues.”

Kolle introduced two of his graduate students to show how fundamental principles of optics and structural color can be applied to different systems. Andrew Blair focuses on material applications of structural color and how colors change as a material’s physical properties change. Anna Feldstein pursues the study of structural color within liquid systems.

“In both of these systems, we can change the color that's observed by shifting something mechanically,” Feldstein said. “We have white light and some wavelengths of light, that, depending on the incoming angle or angle of observance, will interfere constructively or destructively, and then you’ll observe a color.”

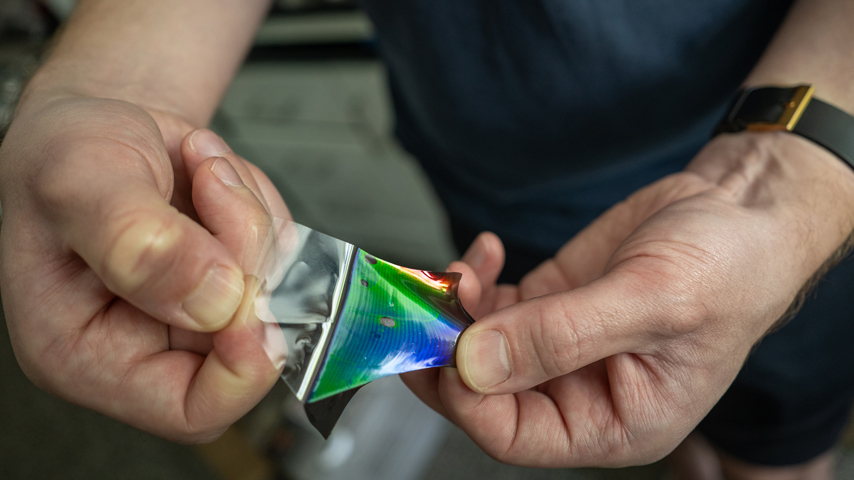

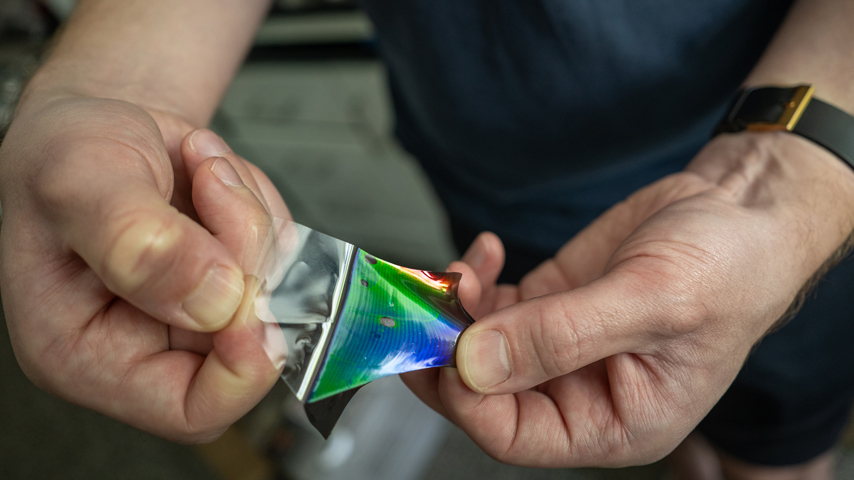

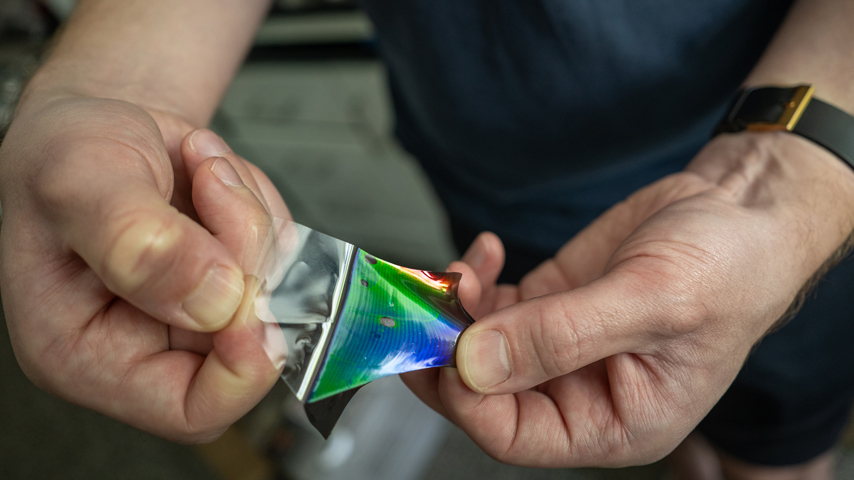

Stretching a polymer with varying layers of refractive index changes the color of the material. Examples from Kolle’s previous work explore the ways the advanced optical function of material structural color could work in commercial applications, such as pressure-monitoring bandages that provide a clear visual indication of appropriate treatment, or knots that demonstrate their strength level through color.

Become a Member: How to Join ASME

“In the liquid droplet system, we can change the structure by playing with the chemistry, and that will also result in a different color that’s observed,” Feldstein said. Kolle noted the application of structural color in liquids offers a greater magnitude of scale and that the size and curvature of droplets and their refractive indices can affect results.

It was the electric blue colors Feldstein saw in the lakes of the Canadian Rockies that often came to mind as she considered the direction her education might take. “[They] contain sediment, but then if you go to scoop up the water, you can see that it's just clear water,” said Feldstein. Childhood fascination, along with an interest in microscale droplets and interfacial tensions intersected to studies in structural color.

Blair’s interest developed after exposure to nanostructure fabrication and lithography techniques during his undergraduate chemistry studies. Advancing his understanding of mechanics and optics at MIT is helping him bring it all together to his near-term goal: Defend his post Ph.D. while wearing a structurally colored shirt woven together by the team. It seems an appropriate step to Blair’s longer-term vision of how structural color can be used to “radically alter the global market of textiles,” said Blair; including fabric’s recyclability and aesthetic properties.

“[Both] are using different structures, but they create the same effect,” said Kolle. “It's always this trick of slowing a bit of light down, advancing some of the light a bit further, and then recombining it.”

Structural color offers an advantage of creating iridescence and other changeable optical effects. With pigments, “You have one color, and everybody sees the same color [from] all directions,” Kolle said. “With these structures, we can create different colors. Upon certain stimuli, and in different directions these colors look can different, and that can define our spaces.”

Said Blair, “It's aesthetic color that you’d have a really hard time producing otherwise.” It also avoids the use of chemicals in pigments and dyes that may not be environmentally friendly or healthy for consumers.

Other potential applications of structural color under exploration range from practical to entertaining.

A responsive optical element could be included in fluids or foods that would tell you the product has spoiled before you opened and smelled it, Kolle said. And, while it may not change the world, one other fun potential use for structural color is to create interactive food experiences. A bartender may someday mix up a drink containing fluid models of structural color, which could change color or appearance when the drink is shaken or if the glass is clinked during a toast, Kolle said.

Kolle, his students, and other colleagues and partners in structural color are bullish on the opportunities for structural color in commercial applications. Some startup funding is available and Kolle and his team are continuing conversations with medical professionals to discover ways structural color may better help meet the needs of patient care. He credits the connections and partnerships between different institutions in helping inform people of the possibilities of the future use of structural color in the open market.

Nancy Kristof is a science writer in Denver.

That natural creation of color crafted from the bending of light through nanostructures, rather than pigments or dyes, inspires Associate Professor Mathias Kolle’s work. He and his graduate students within Massachusetts Institute of Technology’s (MIT) School of Mechanical Engineering are part of a broader, global group of students, researchers, and engineers exploring the process and possibilities of structural color.

Their research on how light waves reflect through microscopic geometries translates mechanics into optical cues. Though too small to see with the naked eye, nano- or micro-structures can manipulate waves of light for dynamic visual results. The study of structural color presents opportunities to “push the capacity that materials have to change optics,” Kolle said.

“If we can control the color, then we can control the appearance,” he said. “You can translate mechanical cues, shape and form into optical cues.”

Controlling color

Kolle introduced two of his graduate students to show how fundamental principles of optics and structural color can be applied to different systems. Andrew Blair focuses on material applications of structural color and how colors change as a material’s physical properties change. Anna Feldstein pursues the study of structural color within liquid systems.

“In both of these systems, we can change the color that's observed by shifting something mechanically,” Feldstein said. “We have white light and some wavelengths of light, that, depending on the incoming angle or angle of observance, will interfere constructively or destructively, and then you’ll observe a color.”

Stretching a polymer with varying layers of refractive index changes the color of the material. Examples from Kolle’s previous work explore the ways the advanced optical function of material structural color could work in commercial applications, such as pressure-monitoring bandages that provide a clear visual indication of appropriate treatment, or knots that demonstrate their strength level through color.

Become a Member: How to Join ASME

“In the liquid droplet system, we can change the structure by playing with the chemistry, and that will also result in a different color that’s observed,” Feldstein said. Kolle noted the application of structural color in liquids offers a greater magnitude of scale and that the size and curvature of droplets and their refractive indices can affect results.

It was the electric blue colors Feldstein saw in the lakes of the Canadian Rockies that often came to mind as she considered the direction her education might take. “[They] contain sediment, but then if you go to scoop up the water, you can see that it's just clear water,” said Feldstein. Childhood fascination, along with an interest in microscale droplets and interfacial tensions intersected to studies in structural color.

Blair’s interest developed after exposure to nanostructure fabrication and lithography techniques during his undergraduate chemistry studies. Advancing his understanding of mechanics and optics at MIT is helping him bring it all together to his near-term goal: Defend his post Ph.D. while wearing a structurally colored shirt woven together by the team. It seems an appropriate step to Blair’s longer-term vision of how structural color can be used to “radically alter the global market of textiles,” said Blair; including fabric’s recyclability and aesthetic properties.

“[Both] are using different structures, but they create the same effect,” said Kolle. “It's always this trick of slowing a bit of light down, advancing some of the light a bit further, and then recombining it.”

Structural color advantages

Structural color offers an advantage of creating iridescence and other changeable optical effects. With pigments, “You have one color, and everybody sees the same color [from] all directions,” Kolle said. “With these structures, we can create different colors. Upon certain stimuli, and in different directions these colors look can different, and that can define our spaces.”

Said Blair, “It's aesthetic color that you’d have a really hard time producing otherwise.” It also avoids the use of chemicals in pigments and dyes that may not be environmentally friendly or healthy for consumers.

Other potential applications of structural color under exploration range from practical to entertaining.

More for You: Image Capturing Devide Mimics the Human Eye

Another of Kolle’s students is exploring how structural color can be used to identify and sort bottles, leading to new ideas of its use to advance recycling. Some of Kolle’s other colleagues are studying how structural color may be used to quickly and clearly indicate characteristics of the foods we consume.A responsive optical element could be included in fluids or foods that would tell you the product has spoiled before you opened and smelled it, Kolle said. And, while it may not change the world, one other fun potential use for structural color is to create interactive food experiences. A bartender may someday mix up a drink containing fluid models of structural color, which could change color or appearance when the drink is shaken or if the glass is clinked during a toast, Kolle said.

Kolle, his students, and other colleagues and partners in structural color are bullish on the opportunities for structural color in commercial applications. Some startup funding is available and Kolle and his team are continuing conversations with medical professionals to discover ways structural color may better help meet the needs of patient care. He credits the connections and partnerships between different institutions in helping inform people of the possibilities of the future use of structural color in the open market.

Nancy Kristof is a science writer in Denver.

Pulse of the Profession: Design for Manufacturing

Supported by real-time data detailing specific plant capabilities and collaborations with factory-floor experts, design teams can digitally prototype parts and products.