3D-Printed Lattices Optimize Strength-to-Weight Ratios

3D-Printed Lattices Optimize Strength-to-Weight Ratios

Design benefits include reduced material use, lightweighting, increased surface area, energy absorption, customizable designs, material choices, and aesthetic appeal.

A fundamental design element in nature is the lattice—for example, the internal structure of dragonfly wings, bones, and mineral structures. Lattices enable high strength-to-weight ratios and have inspired engineering design for centuries. These structures can be visually stunning themselves because of the open space and transparency they create within the larger design—for example, the Eiffel Tower, essentially a lattice framework with repeating elements, is one of the most attractive structures in the world.

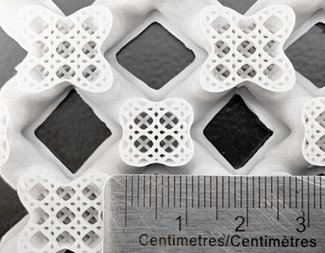

Lattices—networks of crosshatch sections consisting of cells, nodes, struts, and beams—are essential to engineering design. When linked together, lattices can form a “lattice geometry” that consists of a single geometric lattice pattern that repeats in order to occupy space within the design. Lattices can enhance various areas of performance—and use less material—without weakening the object.

Additive manufacturing/3D printing (AM/3DP) techniques have enabled the creation of very intricate lattice designs, especially at the micro scale, that would be impossible to create with standard machining methods, thereby expanding design opportunities for reinforcing and optimizing micro architectures. Because lattices typically have very small and complex features, AM/3DP is often the best manufacturing approach.

3D-printed lattice structures are a powerful design tool. Lattices provide unique design advantages that are very difficult to provide using conventional manufacturing methods. A sound understanding of the advantages of incorporating lattice structures into engineering design will result in more innovative and robust products that impart greater functionality and durability, especially for prototypes and production parts.

Design advantages of 3D-printed lattice structures include:

Reduced material use. Lattices can greatly reduce the amount of material that is used in making a product by removing most of the material from non-critical areas, creating open space. This speeds up production and reduces costs.

Lightweighting. Reducing the material used results in significant weight reduction while still retaining the structural integrity of the object. Depending on the type of lattice selected, weight savings can be dramatic: For example, the reduced amount of energy consumed by vehicles or the lighter weight of gear carried by soldiers on patrol.

More for You: Using Micro 3D Printing for Short Run Production

Increased surface area. Lattice structures allow engineers to increase overall surface area in the most effective way possible, which is especially helpful for applications that involve heat exchange or chemical catalysis. Because lattice structures create more open space, heat is dissipated more evenly and at higher rates.

Material choices. 3D printing can be accomplished using a great variety of materials, including metals, thermoplastics, and ceramics. Selecting the correct lattice material with the best combination of physical and chemical properties is critical for a successful project. For example, elastomers can reduce weight without impacting resistance and flexibility.

Energy absorption. Lattice structures have many properties that are advantageous for absorbing energy. By varying the density and cell type in different areas, a product can be made to absorb energy more effectively in multiple directions.

Customizable. 3D-printed lattices can be customized to meet the specific performance needs of new products. By adjusting the size, thickness, and locations of lattice structures, engineers can control characteristics such as heat dissolution, flexibility, vibration, impact resistance, and noise reduction.

Editor's Pick: New 3D-Printable Ink for Energy Recovery

As products continue to get smaller and more complex, so must their components, including lattices. AM/3DP is increasingly becoming the preferred technology for making these parts at the micro-scale (100 microns or less in size). It is also becoming easier to produce and customize 3D-printed lattice structures, as well as make them aesthetically pleasing to the eye) by using advanced lattice-generating software products developed by a number of firms.

AM/3DP technologies and materials will continue to advance at a rapid pace, providing a wider range of design possibilities for making more robust, durable, and lightweight products with increasingly complex lattice structures at smaller scales, creating new trends in functional design.

Mark Crawford is an engineering and technology writer in Corrales, N.M.

Lattices—networks of crosshatch sections consisting of cells, nodes, struts, and beams—are essential to engineering design. When linked together, lattices can form a “lattice geometry” that consists of a single geometric lattice pattern that repeats in order to occupy space within the design. Lattices can enhance various areas of performance—and use less material—without weakening the object.

Additive manufacturing/3D printing (AM/3DP) techniques have enabled the creation of very intricate lattice designs, especially at the micro scale, that would be impossible to create with standard machining methods, thereby expanding design opportunities for reinforcing and optimizing micro architectures. Because lattices typically have very small and complex features, AM/3DP is often the best manufacturing approach.

3D-printed lattice structures are a powerful design tool. Lattices provide unique design advantages that are very difficult to provide using conventional manufacturing methods. A sound understanding of the advantages of incorporating lattice structures into engineering design will result in more innovative and robust products that impart greater functionality and durability, especially for prototypes and production parts.

Design advantages of 3D-printed lattice structures include:

Reduced material use. Lattices can greatly reduce the amount of material that is used in making a product by removing most of the material from non-critical areas, creating open space. This speeds up production and reduces costs.

Lightweighting. Reducing the material used results in significant weight reduction while still retaining the structural integrity of the object. Depending on the type of lattice selected, weight savings can be dramatic: For example, the reduced amount of energy consumed by vehicles or the lighter weight of gear carried by soldiers on patrol.

More for You: Using Micro 3D Printing for Short Run Production

Increased surface area. Lattice structures allow engineers to increase overall surface area in the most effective way possible, which is especially helpful for applications that involve heat exchange or chemical catalysis. Because lattice structures create more open space, heat is dissipated more evenly and at higher rates.

Material choices. 3D printing can be accomplished using a great variety of materials, including metals, thermoplastics, and ceramics. Selecting the correct lattice material with the best combination of physical and chemical properties is critical for a successful project. For example, elastomers can reduce weight without impacting resistance and flexibility.

Energy absorption. Lattice structures have many properties that are advantageous for absorbing energy. By varying the density and cell type in different areas, a product can be made to absorb energy more effectively in multiple directions.

Customizable. 3D-printed lattices can be customized to meet the specific performance needs of new products. By adjusting the size, thickness, and locations of lattice structures, engineers can control characteristics such as heat dissolution, flexibility, vibration, impact resistance, and noise reduction.

Editor's Pick: New 3D-Printable Ink for Energy Recovery

As products continue to get smaller and more complex, so must their components, including lattices. AM/3DP is increasingly becoming the preferred technology for making these parts at the micro-scale (100 microns or less in size). It is also becoming easier to produce and customize 3D-printed lattice structures, as well as make them aesthetically pleasing to the eye) by using advanced lattice-generating software products developed by a number of firms.

AM/3DP technologies and materials will continue to advance at a rapid pace, providing a wider range of design possibilities for making more robust, durable, and lightweight products with increasingly complex lattice structures at smaller scales, creating new trends in functional design.

Mark Crawford is an engineering and technology writer in Corrales, N.M.

.png?width=854&height=480&ext=.png)