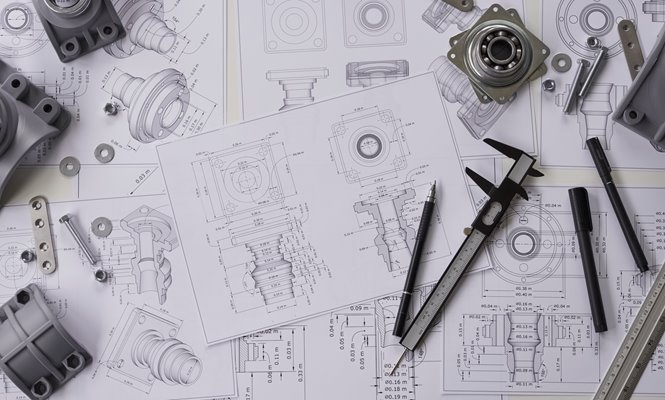

Learn how to take the guesswork out of the manufacturing process, to improve quality and avoid costly mistakes.

After taking the introductory GD&T course, students will grasp the fundamentals of GD&T, such as datums, position with Maximum Material Condition (MMC) and Regardless of Feature Size (RFS) modifiers, parallelism, profile etc. However, they may still lack the intimate knowledge of how to apply geometric tolerancing expertly and perform tolerance stacks to define and optimize their product design.

This Applications and Tolerance Stacks course teaches one how to take GD&T skills to the next level and apply and perform tolerance stacks using a series of case study problems including sheet metal, machinings, plastic parts, castings etc. Being able to identify a tolerance on a part can influence the product’s cost and performance. Learning the skills in this course will help the learner balance functionality with manufacturing capabilities.

The case studies in this course require students to establish datum reference frames and apply geometric tolerancing based on defined functional requirements. Afterwards, they must perform tolerance stacks to ensure design requirements are met. This process links the concept that the proper selection of the datums, as well as position and profile values on individual parts, have a great effect on the accumulation in the overall assembly. The exercises are interactive and discussed in student groups and as a class to support an engaging class environment.

By participating in this course, you will learn how to successfully:

- Employ the proper application of geometric tolerancing on parts and assemblies.

- Perform linear and axial tolerance stacks.

- Reallocate tolerances to meet manufacturing capabilities.

Special Requirements:

Students should bring calculators to class. Participants may bring drawings to class for discussion.

Who Should Attend?

Engineers, designers and drafters, as well as quality, tooling and manufacturing personnel. As a prerequisite, it is recommended the students attend the Geometric Tolerancing Fundamentals class or have a strong understanding in geometric tolerancing fundamentals.

Course Materials (included in the purchase of the course)

- All participants receive a copy of GeoTol Applications and Tolerance Stacks (Please note that the books are shipped and we cannot guarantee that they will arrive in time for the start of class for late registrants. If your shipping address is outside of the U.S. or Canada, we can only provide digital access to the books).

- Downloadable job aid: Tolerance Stack Spreadsheet.

These items will serve as valuable resources long after the training is complete.

Topics covered in this course include:

- Fixed and Floating Fastener Formulas: Calculating Position Tolerances

- Linear Stacks, Vector Method with Plus Minus Tolerances

- Linear Stacks, Vector Method with Profile Tolerances

- Practical Problem: Grommet Assembly

- Practical Problem: Powder Case Assembly

- Practical Problem: Step Bracket Assembly (sheet metal)

- Detail Axial Boundary Stacks

- Assembly Axial Boundary Stacks

- Practical Problem: Optic Connector with complex alignment requirements

This ASME Virtual Classroom course is held live with an instructor on our online learning platform. Certificate of completion will be issued to registrants who successfully attend and complete the course.