Already completed AM210?

Apply what you have learned to three common AM case studies: Replication, Adaptation, and Optimization. This series of courses includes 3 project-based courses. In these Project-based courses an instructor will grade assignments and provide feedback within 2-3 business days.

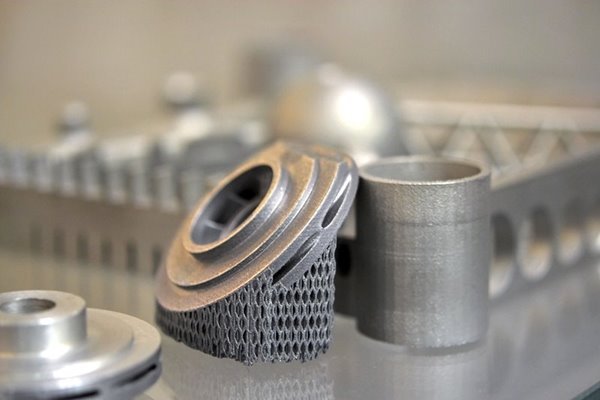

This series of courses provides the key foundational knowledge to properly evaluate Additive Manufacturing (AM) as a potentially viable technology solution coupled with the in-depth technical knowledge necessary to efficiently shepherd AM parts from design, through post-processing and eventually into the market through three case studies: replication, adaptation, and optimization.

Each case study allows the learner to dive deeper into each use case and give the learner the opportunity to apply what they have learned by completing a variety of assessments and assignments.

- Replicate covers a just-in-time solution, e.g., when you're in need of an exact copy or a legacy part that no longer is in production or not readily available.

- Adapt covers a situation in which you need to adapt an existing design, e.g., to reduce costs, enhance performance, and/or excessive post-processing of your part.

- Optimize provides freedom to change part geometry e.g., to ensure significant performance improvements; parts that print quickly, cost-effectively and use material most efficiently.

By completing this learning path, you will learn how to successfully:

- Leverage Replicate Adapt Optimize™ Framework

- Ensure quality of a print through the use of industry best practices

- Identify and leverage the additive manufacturing design techniques that are specific to the Replicate, Adapt, and Optimize use cases.

Who should attend?

- Engineering teams at design and manufacturing firms, as well as individuals

- Early to mid-career engineers, including design engineers, materials engineers, manufacturing engineers, and others with an interest in design for additive manufacturing with metals

- Business Managers including directors of program management, directors of strategy/supply chain, financial analysts, or controllers

Course participants are expected to:

- Have already successfully completed AM210: Design for Additive Manufacturing with Metals Course

- Have access to CAD and know how to use it

- Maintain a basic understanding of analysis tools (i.e., FEA, CFD, and GD&T methods)

- Be familiar with traditional manufacturing processes (i.e., machining/milling, casting, and forging)

- Possess basic knowledge of engineering and intellectual property ethics, such as the ASME Code of Ethics of Engineers

- Ideally, have some experience with 3D printing and plastics/polymers (not required)

A Certificate of Completion will be issued to registrants who successfully complete each course in this Design for Additive Manufacturing with Metals Case Studies Package.