Bolted Joint Assembly Principles Per ASME PCC-1-2022 (Virtual Classroom)

Course Type:

Course Number:

Credits:

Language:

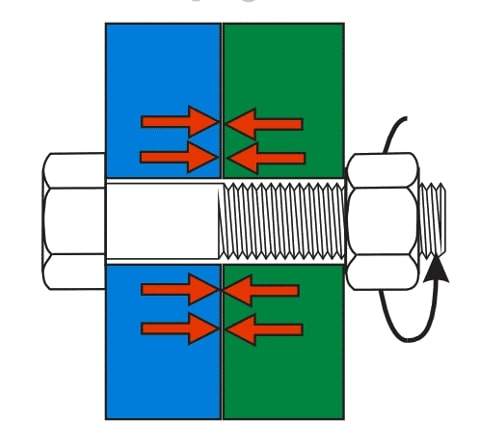

Identify the principles of joint design, assembly, and reliability per ASME PCC-1 2022.

{{activeProduct.Title}}

Digital products are restricted to one per purchase.

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPrice) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPriceSale) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPrice) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPriceSale) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.MemberPrice) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.MemberPriceSale) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

*Excluding Lite Members

Final invoices will include applicable sales and use tax.

Print or Share

Sorry, we only have available spots for this course. Would you like to add those to your cart?