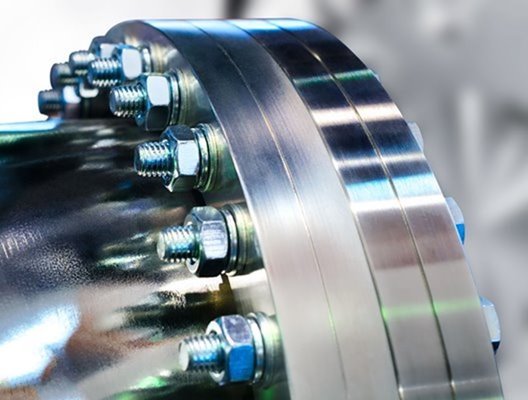

The bolted joint is an important element of many products, systems, and structures. Learn the fundamentals of threaded fasteners with a focus on bolts, bolted joints, bolted flange joints, including their strength, behavior, design approaches and failure prevention. Bolted joints with and without gaskets are presented to provide a broad understanding of the various loads and stresses bolted joints experience.

In this guided study course, students will use illustrative case histories and calculation examples to design and apply safe and reliable bolted joints. Bolt tightening pre-load calculations presented will consider the many variables that affect a bolted joint for the student to diagnose and solve bolted joint problems and specify appropriate assembly practices.

Beginning with an introduction to the basic mechanics, thread standards and materials for the bolted connection and its components, the student gains an appreciation of the challenges presented to the designer and user to apply and maintain a safe and appropriate clamping load for various applications. The behavior of bolted joints is examined during assembly and in-service. Failure mechanisms are reviewed, and avoidance guidelines given including self-loosening, fatigue and corrosion. Clamping force reduction mechanisms are presented including embedment, elastic interaction, thermal and mechanical effects. Proper assembly of bolted joints are presented using manual, torque, turn of the nut, stretch and direct tension methods. The course prepares the student for optimizing the bolted joint design with bolt torque and stretch calculations along with selecting the assembly method most applicable for bolts, screws and stud bolts with a threaded nut or blind tapped hole.

You will learn to:

- Recognize various thread profiles, classes, tolerances and allowances for threaded fasteners.

- Calculate the optimum assembly bolt preload using torque and bolt stretch calculation methods

- Assess the mechanical stress and strain of a bolted joint and the challenges for specifying an optimum bolt load, given the external loads

- Explain how to increase the functional life of a bolted joint with an understanding of failure mechanisms such as pre-load loss, fatigue and self-loosening

- Explain the merits of torque, turn of the nut, stretch and direct tension methods for assembling bolted joints

- Recognize the importance of assembly procedures using proven bolting patterns

Recommended Reading

It is recommended that you obtain either one of the following:

- Bickford, John, H. (1997). An Introduction to Design and Behavior of Bolted Joints, 3rd Edition. New York: CRC Press; or

- Bickford, John, H. & Payne, James, R. (2007). Introduction to the Design and Behavior of Bolted Joints: Non-Gasketed Joints, 4th Edition, Volume 1. New York: CRC Press.

Who Should Attend

Engineers, engineering managers/supervisors and technical staff involved in the design, specification, procurement, application, inspection, maintenance, assembling and project management of products and equipment utilizing bolts and bolted joints.

Participants are recommended to have at least 2 years of engineering experience, as the learning content involves solving equations. While a technical background is helpful, enough general information is included in the course to be beneficial for those wanting to expand their knowledge with no engineering experience.

A Certificate of Completion will be issued to registrants who successfully complete this course.

To take this course you should have a personal computer, Web browser, Internet connection, and software to display PDF files (such as Adobe Reader®).