Robot Introduces Technology to Terroir

Robot Introduces Technology to Terroir

Italian Institute of Technology’s Soft Robotics for Human Cooperation and Rehabilitation Laboratory is working on innovative technology to support economic growth and sustainable agriculture.

Every once in a while, as I breathe in the fragrant bouquet of a glass of wine, I imagine one day owning a vineyard. Of course, in my wine-making daydreams, I don’t consider the hard work involved. Before any grape is ever harvested for wine, vintners must plant, prune, irrigate, and nurture each vine—protecting the precious fruit from pests and poor weather.

“Today, in Italy, there is already a shortage of workers with the necessary knowledge to care for grapes,” said Manuel G. Catalano, a researcher at the Italian Institute of Technology (IIT)’s Soft Robotics for Human Cooperation and Rehabilitation Laboratory.

“The problem of labor shortage is common in almost every sector at this moment but particularly in the vineyards,” he said. “That kind of work is not necessarily appealing to the younger generation. But as we talked to vineyard stakeholders, we realized it might be possible to design a robotic assistant who could do the repetitive, everyday work in vineyard production and help.”

To provide such a robotic assistant, Catalano and his team, as part of the JOiiNT LAB initiative (an academic-industry consortium that is working to solve problems together in Italy’s Bergamo region), designed Frasky. The JOiiNT LAB is working to advance innovative new technologies in the region to support economic growth and sustainable agriculture efforts.

The four-wheeled outdoor mobile platform was specifically designed to move about the vineyard. As a result, Frasky can navigate the uneven terrain independently. In addition, it can act as a vintner’s assistant, helping with cumbersome daily tasks such as monitoring grape clusters and applying targeted pest or fertilizer treatments when needed.

“This is very important work in the vineyards, and Frasky can be used to do it across the entire year,” he said. “Instead of having a person monitor the health of the grape, Frasky can localize and do it for every single grape in the vineyard so you can see the overall status of the entire area.”

If Frasky notices an issue, the robot can also do the appropriate treatment using a nozzle on his arm, even to the level of the individual grape, thus providing necessary nutrients or pest control only where it is needed. This capability helps vineyards avoid costly and unnecessary blanket spraying, which can be detrimental to the overall environment.

Designing Frasky was not easy. Catalano said he and his team spent a great deal of time working on Frasky’s ability to navigate the uneven terrain around the grape vines.

“These areas are not flat. And, of course, there is rain which can change the softness of the ground,” he said. “That is why we used platforms that were already developed to work in this kind of environment and then adapted them, moving the sensors where they were needed, so they would work better in this type of terrain.”

The group also had to contend with helping Frasky identify the grapes for monitoring purposes, especially as the foliage around them grows thicker, partially obscuring them.

“For this, we trained big artificial intelligence algorithms with many pictures of different grapes so it can identify the single grape when it needs to,” he said.

Finally, there was a matter of being able to manipulate grapes to help better monitor their health. Agricultural robots have long been plagued by difficulties grasping or moving fruit or vegetables without damaging them. Catalano said his lab’s experience in working with soft robots, including soft hand applications, helped Frasky learn how to apply force while still adapting to the shape of the object in a delicate manner.

Finally, there was a matter of being able to manipulate grapes to help better monitor their health. Agricultural robots have long been plagued by difficulties grasping or moving fruit or vegetables without damaging them. Catalano said his lab’s experience in working with soft robots, including soft hand applications, helped Frasky learn how to apply force while still adapting to the shape of the object in a delicate manner.

After testing Frasky in the laboratory, Catalano and colleagues tested the robotic platform in a real-world vineyard in Grumello del Monte. It was able to successfully navigate the vineyard, map the environment, monitor the grapes, and apply treatments from its nozzle. Catalano deems this first version of the system a success—but plans to continue enhancing its capabilities. As they work to meet the needs of modern vintners, he believes Frasky can help keep more small vineyards in Italy, and beyond, in business even as workforce shortages continue.

“We are starting to add new features to the system. For example, we want to add suction to help Frasky analyze the grapes. We are also continuing to stabilize the platform so it can monitor the grapes year-round in different types of vineyard environments with different slopes,” he said. “And then, eventually, we would also like to move to the cutting phase so Frasky could also help with the harvest. It will take some time.”

Kayt Sukel is a technology writer and author in Houston.

“Today, in Italy, there is already a shortage of workers with the necessary knowledge to care for grapes,” said Manuel G. Catalano, a researcher at the Italian Institute of Technology (IIT)’s Soft Robotics for Human Cooperation and Rehabilitation Laboratory.

“The problem of labor shortage is common in almost every sector at this moment but particularly in the vineyards,” he said. “That kind of work is not necessarily appealing to the younger generation. But as we talked to vineyard stakeholders, we realized it might be possible to design a robotic assistant who could do the repetitive, everyday work in vineyard production and help.”

Robot assistant

To provide such a robotic assistant, Catalano and his team, as part of the JOiiNT LAB initiative (an academic-industry consortium that is working to solve problems together in Italy’s Bergamo region), designed Frasky. The JOiiNT LAB is working to advance innovative new technologies in the region to support economic growth and sustainable agriculture efforts.

The four-wheeled outdoor mobile platform was specifically designed to move about the vineyard. As a result, Frasky can navigate the uneven terrain independently. In addition, it can act as a vintner’s assistant, helping with cumbersome daily tasks such as monitoring grape clusters and applying targeted pest or fertilizer treatments when needed.

“This is very important work in the vineyards, and Frasky can be used to do it across the entire year,” he said. “Instead of having a person monitor the health of the grape, Frasky can localize and do it for every single grape in the vineyard so you can see the overall status of the entire area.”

If Frasky notices an issue, the robot can also do the appropriate treatment using a nozzle on his arm, even to the level of the individual grape, thus providing necessary nutrients or pest control only where it is needed. This capability helps vineyards avoid costly and unnecessary blanket spraying, which can be detrimental to the overall environment.

Difficult design

Designing Frasky was not easy. Catalano said he and his team spent a great deal of time working on Frasky’s ability to navigate the uneven terrain around the grape vines.

“These areas are not flat. And, of course, there is rain which can change the softness of the ground,” he said. “That is why we used platforms that were already developed to work in this kind of environment and then adapted them, moving the sensors where they were needed, so they would work better in this type of terrain.”

The group also had to contend with helping Frasky identify the grapes for monitoring purposes, especially as the foliage around them grows thicker, partially obscuring them.

“For this, we trained big artificial intelligence algorithms with many pictures of different grapes so it can identify the single grape when it needs to,” he said.

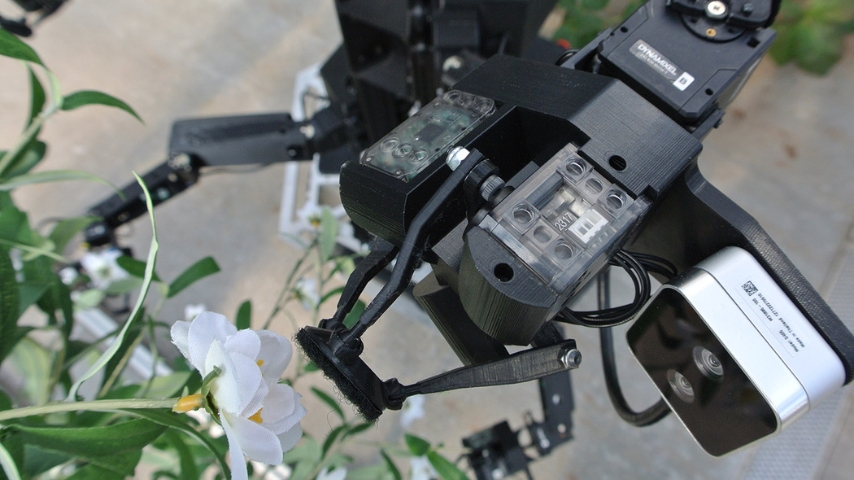

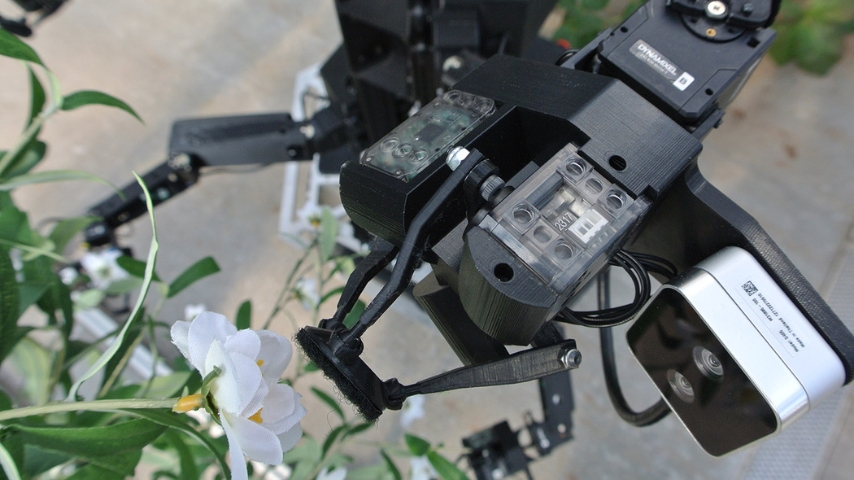

Six-Armed Robot Works as a Precision Pollinator

With six arms, a Kiwi drive, and custom detectors designed for contact-based pollination, the precision Stickbug reaches flowers growing above the greenhouse floor while navigating narrow plant rows.

After testing Frasky in the laboratory, Catalano and colleagues tested the robotic platform in a real-world vineyard in Grumello del Monte. It was able to successfully navigate the vineyard, map the environment, monitor the grapes, and apply treatments from its nozzle. Catalano deems this first version of the system a success—but plans to continue enhancing its capabilities. As they work to meet the needs of modern vintners, he believes Frasky can help keep more small vineyards in Italy, and beyond, in business even as workforce shortages continue.

“We are starting to add new features to the system. For example, we want to add suction to help Frasky analyze the grapes. We are also continuing to stabilize the platform so it can monitor the grapes year-round in different types of vineyard environments with different slopes,” he said. “And then, eventually, we would also like to move to the cutting phase so Frasky could also help with the harvest. It will take some time.”

Kayt Sukel is a technology writer and author in Houston.