Refueling the Engine

Refueling the Engine

Revamped diesel technology breaks the link between the choice of engine and the kind of fuel needed to run it. Where will that opportunity lead?

The diesel engine serves as the workhorse of the modern world. It is rugged, reliable, and powers most of the planet's freight-hauling trucks, earth-moving equipment, and farm machinery. Diesel engines have improved the quality of life and delivered energy access to billions of people, providing essential access to goods, transportation, and electricity. It’s an incredible, essential technology for converting high energy-density, easily storable liquid fuels into work.

But diesel engine fuels cause unsustainable greenhouse gas impacts. According to the U.S. Energy Information Administration, diesel use accounted for about 26 percent of total U.S. transportation sector carbon dioxide emissions, the equivalent of about 10 percent of total U.S. energy-related CO2 emissions in 2021. This negative impact arises from the fossil fuel diesel uses, rather than the engine design. Fuels cleaner than petroleum-based fuels exist and are being refined constantly, but greater flexibility on feedstock and fuel composition is needed.

That challenge is an engineering opportunity. Free the diesel engine from petroleum-derived fuels—or even from fuels that are required to be chemically similar to diesel—so that it can operate on any fuel and it can meet its essential economic functions while greenhouse gas emissions are reduced.

Achieving this was the goal of the thesis work of my co-founder, BJ Johnson, during our doctoral studies at Stanford University. Since establishing ClearFlame Engine Technologies in 2016 to launch the commercialization of this technology, we’ve shown it is possible to adapt diesel technology to operate on any fuel, regardless of cetane number, and in a way that conserves the same thermodynamic cycle, combustion process, and thus all the progress that has been built over a century of this incredible machine, and to do so in a way that preserves and promotes the increase in quality of life that access to energy provides.

Similar Reading: Video: Fighting Climate Change with Vodka and Jet Fuel

This work enables us to ask a provocative question: “If you could use any fuel, which fuel would you use and why?”

Historically the engine-fuel pairing has dictated this choice, but going forward, fuel innovation can advance without the constraint of creating molecules that resemble what can be easily produced from a barrel of oil. Drop-in fuels have a place in the transition, but many, including diesel-like molecules, have limited feedstocks and are expensive to synthesize. As a result, there is much greater opportunity in opening engines up to all fuels.

With a “fuel-adaptable engine” the entire molecular landscape is open to find solutions which are low cost, low carbon, regionally abundant, or embody any number of other desirable attributes.

In conventional diesel engines, the ready auto-ignition of diesel fuel (its high cetane number) is an essential property that makes the cycle possible. Traditionally, any deviation from a diesel-like cetane number required a change of approach, such as using a lower-efficiency spark-ignited architecture or changing the level of premixing of the air and fuel before combustion.

Alternately, using a low-cetane fuel in conjunction with a high-cetane one to control reaction kinetics has led to dual-fuel engines that operate on alternatives. Premixing and dual-fueled approaches have led to things like HCCI, PCCI, RCCI, or the entire alphabet soup of acronyms that combustion researchers love.

These approaches invariably come with added complexity which has limited their commercial deployment to applications that will accept them. For instance, marine applications are accepting of dual-fuel engines, whereas on-road trucking is not.

But premixing or using a dual fuel strategy aren’t the only ways to overcome the challenge of igniting difficult-to-ignite fuels. At ClearFlame, we started with the insight that while low-cetane fuels don’t ignite very readily, every fuel can be made to ignite more quickly at higher temperatures. We then asked, “What temperatures would we have to reach such that when we inject any given fuel of choice, it would ignite right away the way diesel does at typical engine operating temperatures?”

The answer is of course dependent on the chosen fuel. For example, alcohol fuels like methanol and ethanol only require that intake temperatures be about 50 °C to 60 °C higher than in conventional diesel engines to produce the right conditions to behave like diesel fuel and readily auto-ignite upon fuel injection. More auto-ignition resistant fuels such as hydrogen or ammonia require slightly higher temperatures, but the principle of “fuel flexibility at high enough temperature” remains.

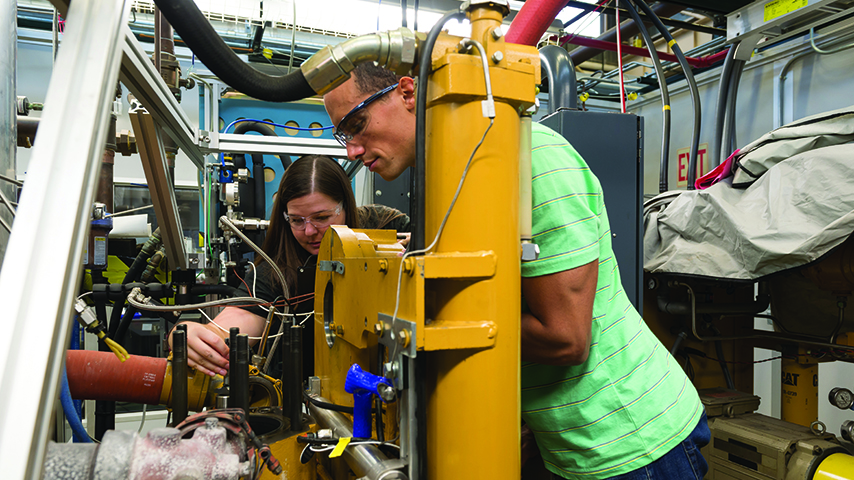

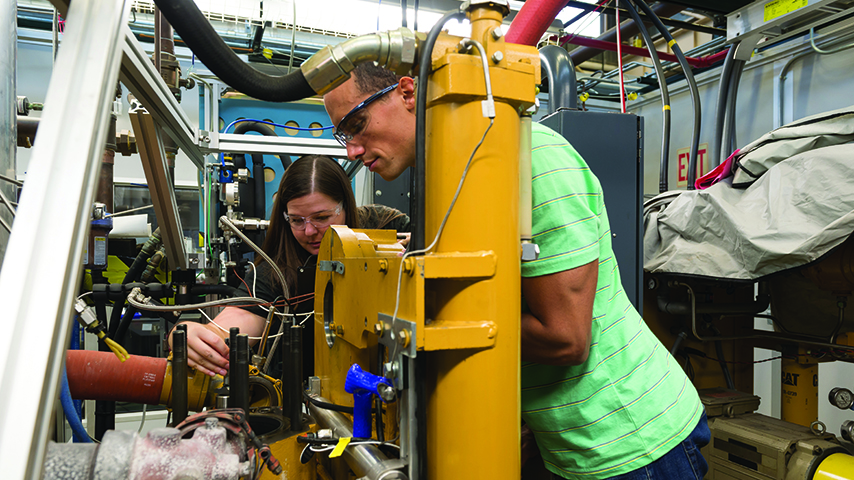

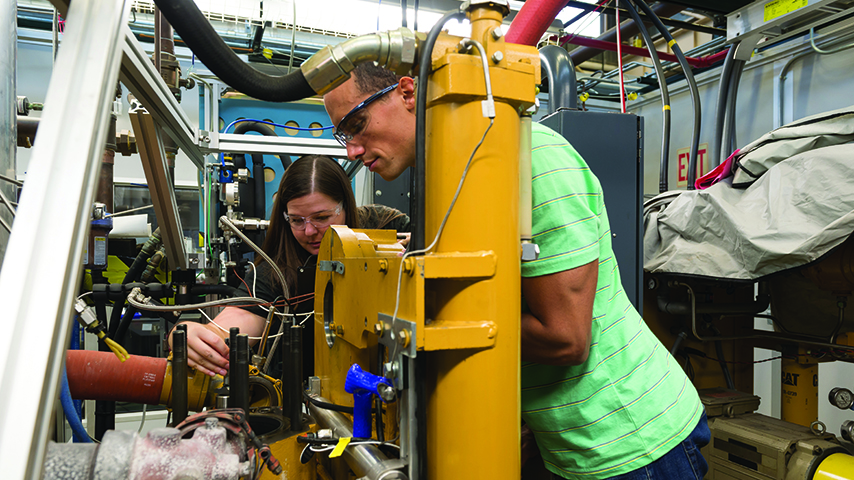

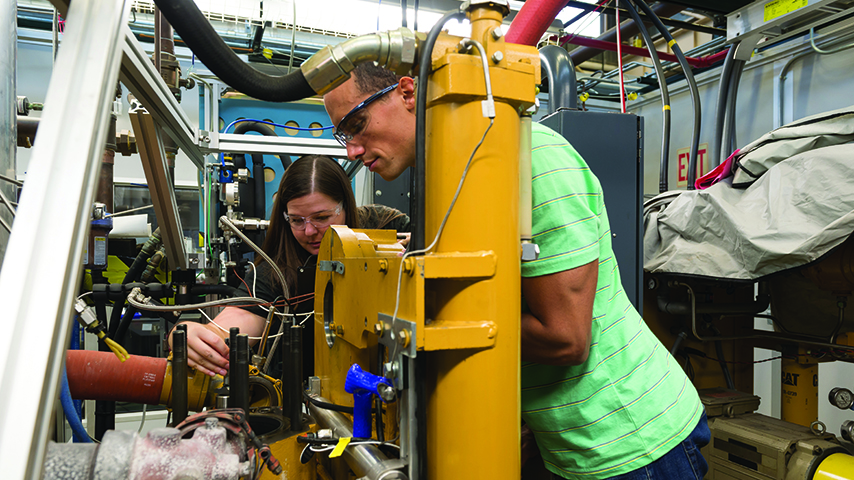

To build a fuel-adaptable engine platform, we begin with an existing diesel engine platform and make modifications.

The first change is the fuel system, using compatible materials and adjusting for any difference in volumetric energy density. For example, it takes 2.3 times as much methanol to reach the same fuel energy as diesel, and thus the fuel injection must be 2.3 times larger. For ethanol that ratio is 1.7 times.

We also add some surface treatments and our own engine control unit to take greater advantage of the benefits of the cleaner-burning fuels we use; for instance, we optimize for low engine-out nitrogen oxides (NOx) in the absence of soot formation. We’ve shown a 10 times reduction in engine-out NOx from production diesel calibrations without forming soot or losing efficiency.

That temperature increase to promote rapid auto-ignition of any chosen fuel is accomplished by utilizing the energy already available in the engine and redirecting it. The diesel engine’s compressor produces hot compressed air; typically, that air is cooled in the charge air cooler (CAC). We can redirect the hot air from the compressor and bypass the CAC directly to the intake port. We can also remove the exhaust gas recirculation cooler to enable use of hot combustion products. These changes provide sufficient thermal energy to operate the entire engine map on any fuel. To start the engine, we need an initial heat source, such as intake grid heaters, glow plugs, or other start aids typically used on diesel engines in cold weather to heat the air for the first few cycles.

These changes allow a diesel platform to operate on any fuel while achieving performance identical to the base diesel engine—an identical torque curve—not “diesel-like” but still with sacrifices relative to diesel, or de-rated at low engine speed like spark-ignition strategies. The non-premixed nature of combustion preserves the ability to deliver the low-speed torque that users have come to rely upon from their engines.

Become a Member: How to Join ASME

The emissions profile is significantly different, however. Fuels like ethanol, methanol, ammonia, and other small-molecule alternative fuels don’t form appreciable soot even when burned in a non-premixed manner. In fact, engine-out soot emissions are only one-tenth of the EPA tailpipe limit, meaning the engine can meet soot regulations without a diesel particulate filter. Further, by starting with low-soot fuels, the engine can be calibrated to avoid the usual trade-off between soot formation and NOx. Finally, and perhaps most importantly in the current climate crisis, these fuels can be sourced from renewable sources to drastically reduce GHG emissions.

The result is an engine that acts like a diesel in every way except for the fuel you put into it and the lower criteria emissions and lower greenhouse gases coming out. The solution scales the same way the diesel cycle does and works well even in engines with large bore sizes, which are often the engines in the hardest-to-electrify applications.

We’ve retrofitted four diesel trucks (plus one genset) to operate on alcohol fuel and are driving them through demanding road tests, including regularly pulling 80,000-pound gross vehicle weight. The vehicles have a range of over 1,000 miles, and for liquid fuels like alcohols, installing refueling infrastructure along key fleet routes is very simple. Any of the quarter million diesel mechanics in the country can work on these vehicles, and because we are making minor changes to traditional parts, we can leverage existing supply chains and integrate this solution either as a new OEM build or as a retrofit.

Given the technology is compatible with any fuel, it is time to ask: What factors should be considered when selecting a fuel?

One obvious factor is that it should be low carbon—specifically low greenhouse gas on a lifecycle basis, in contrast to looking only at tailpipe emissions. The complete lifecycle framework is key here. The atmosphere can be thought of as a “giant joint checking account,” where the net of deposits and withdrawals of greenhouse gases affect the balance rather than any single transaction.

Comprehensive lifecycle analyses, such as those conducted by David L. MacIntosh of Harvard University or underpinning Argonne National Laboratory’s GREET model (an open-source lifecycle analysis tool for energy and transportation), show that decarbonized fuels and biofuels have very low carbon intensities.

There are other important considerations as well. The fuel should be low-cost, energy-dense, already at scale, and readily available. Across different applications in different locations, no single fuel may be the best choice. Still, it is essential to think about these attributes more holistically than is customary today.

The first factor our customers ask us about is cost. Operating costs will always depend on how much an alternative fuel costs and how efficiently the engine can use it. Since fuels differ widely in their energy density, units of volume aren’t the best way to do an “apples to apples” comparison among fuels. For example, when we show our trucks, people always ask us about the miles per gallon, but the cost per mile is actually what people are trying to understand.

Consuming more gallons of a lower energy density fuel (like ethanol) does not mean higher costs, and fuels like ethanol are lower cost on an energy basis than diesel fuel. That means you can purchase 1.7 gallons of ethanol (the ratio of energy densities) for less than you can purchase a single gallon of diesel.

Even with the energy-density penalty, ethanol provides a 30 cent per mile savings over diesel fuel in a semi-truck, providing very compelling economics for fleet operators. And given the low capital cost of engine technology and liquid alternative fuel infrastructure, this per-mile cost savings also leads to a lower total cost of ownership than for diesel vehicles.

Availability is typically the second question customers ask about, which is usually a function of fueling infrastructure. In contrast to passenger cars, refueling of diesel-powered heavy equipment is more frequently done independently, where a farm, fleet, or mining operation takes delivery from fuel wholesalers to refuel onsite rather than driving to a retail station. This allows many end-use operations much more autonomy to adopt an alternative fuel, even if retail availability may be initially limited.

In the U.S., almost every wholesale fuel terminal in the country offers three fuels: gasoline, diesel, and ethanol. As a result, taking delivery of a tankerful of ethanol is as easy as taking delivery of diesel fuel today, and future fuels can be distributed to customers in a similar fashion. That simplicity can ease the transition to low-carbon liquid fuels.

Another question customers ask is, “How much of that fuel is there?” That gets to the issue of scale and scalability. Scale determines how much climate impact and market relevance a fuel has today. There is a near-term opportunity in the U.S. to use ethanol, due to its multi-decade head start from U.S. investments in ethanol production. Long-term and globally, methanol, ammonia, or other energy carriers are likely to emerge as fuels of choice due to their scalability, which determines the fuel’s maximum potential decarbonization potential.

Scale and scalability must also be considered when evaluating greenhouse gas benefits, and carbon intensity figures should be coupled with information on the present and future scalability of that fuel to accurately assess its true decarbonization potential.

Another consideration of scalability is what other applications might be competing for that fuel. For example, renewable diesel has some attractive properties, but the production of sustainable aviation fuel is poised to dominate the demand for the lipid-based feedstocks that renewable diesel production requires. It also takes five times as many acres to grow crops for lipids as it does to grow the feedstock to make the energy equivalent of alcohol.

Based on our research, we have concluded that alcohols are the best alternative fuels when considering the range of factors that impact customer needs and climate goals. They are liquids under ambient conditions, making storage and dispensing easy. They are simple molecules that can be made or synthesized from a variety of feedstocks, in contrast to larger molecules like those in diesel or gasoline.

As a result, they are abundant, low-cost, and low-carbon. For example, ethanol in the U.S. is lower carbon than diesel by 45 percent on a lifecycle basis, even coming in lower than grid-average electricity.

But different applications currently reliant on diesel fuel may weigh the benefits differently. Our engine needs to accommodate applications where another alternative would best serve the customer, such as if a fleet had a preference for synthetic gasoline to have an immediate drop-in that was also compatible with new vehicles.

You Might Also Enjoy: Energy Blog: Twilight for ICE Vehicles?

Providing a solution with component-level changes allows for retrofitting of existing vehicles as well as new, allowing multiple options to integrate into existing operations. Because we aren’t hitched to any single fuel, our technology and our customers have the potential to adapt to current conditions and future developments.

That potential flexibility is perhaps the greatest benefit of having an engine that can ignite a wide range of fuels. We have preserved the underlying architecture of the diesel engine, and by making changes at the component level we have liberated the engine from its need to operate on petroleum-derived fuels. The progress we have made is exciting: We’ve run our engine back-to-back days on ethanol, methanol, hydrous ethanol, and E85.

It's too easy to look at the push to electrify transportation and conclude that no other alternatives are needed, or that pursuing alternatives in parallel will somehow diminish electrification. I believe that way of thinking is missing the massive scale of the challenge we face. We need a “both/and” attitude.

Low-cost and simple-to-adopt solutions to free diesel engines from petroleum dependence will enable internal combustion engines to lead the way in near-term decarbonization, while continuing to scale and dominate heavy-duty applications. By taking a multi-pronged approach and complementing electrification, the overall rate of decarbonization will be faster than any single technology could accomplish.

Julie Blumreiter is co-founder and chief technology officer at ClearFlame Engine Technologies, based in Geneva, Ill. Her article was adapted from a presentation Blumreiter gave at the ASME ICE Forward Conference in October 2022.

But diesel engine fuels cause unsustainable greenhouse gas impacts. According to the U.S. Energy Information Administration, diesel use accounted for about 26 percent of total U.S. transportation sector carbon dioxide emissions, the equivalent of about 10 percent of total U.S. energy-related CO2 emissions in 2021. This negative impact arises from the fossil fuel diesel uses, rather than the engine design. Fuels cleaner than petroleum-based fuels exist and are being refined constantly, but greater flexibility on feedstock and fuel composition is needed.

That challenge is an engineering opportunity. Free the diesel engine from petroleum-derived fuels—or even from fuels that are required to be chemically similar to diesel—so that it can operate on any fuel and it can meet its essential economic functions while greenhouse gas emissions are reduced.

Achieving this was the goal of the thesis work of my co-founder, BJ Johnson, during our doctoral studies at Stanford University. Since establishing ClearFlame Engine Technologies in 2016 to launch the commercialization of this technology, we’ve shown it is possible to adapt diesel technology to operate on any fuel, regardless of cetane number, and in a way that conserves the same thermodynamic cycle, combustion process, and thus all the progress that has been built over a century of this incredible machine, and to do so in a way that preserves and promotes the increase in quality of life that access to energy provides.

Similar Reading: Video: Fighting Climate Change with Vodka and Jet Fuel

This work enables us to ask a provocative question: “If you could use any fuel, which fuel would you use and why?”

Historically the engine-fuel pairing has dictated this choice, but going forward, fuel innovation can advance without the constraint of creating molecules that resemble what can be easily produced from a barrel of oil. Drop-in fuels have a place in the transition, but many, including diesel-like molecules, have limited feedstocks and are expensive to synthesize. As a result, there is much greater opportunity in opening engines up to all fuels.

With a “fuel-adaptable engine” the entire molecular landscape is open to find solutions which are low cost, low carbon, regionally abundant, or embody any number of other desirable attributes.

Modifying diesel engines

In conventional diesel engines, the ready auto-ignition of diesel fuel (its high cetane number) is an essential property that makes the cycle possible. Traditionally, any deviation from a diesel-like cetane number required a change of approach, such as using a lower-efficiency spark-ignited architecture or changing the level of premixing of the air and fuel before combustion.

Alternately, using a low-cetane fuel in conjunction with a high-cetane one to control reaction kinetics has led to dual-fuel engines that operate on alternatives. Premixing and dual-fueled approaches have led to things like HCCI, PCCI, RCCI, or the entire alphabet soup of acronyms that combustion researchers love.

These approaches invariably come with added complexity which has limited their commercial deployment to applications that will accept them. For instance, marine applications are accepting of dual-fuel engines, whereas on-road trucking is not.

But premixing or using a dual fuel strategy aren’t the only ways to overcome the challenge of igniting difficult-to-ignite fuels. At ClearFlame, we started with the insight that while low-cetane fuels don’t ignite very readily, every fuel can be made to ignite more quickly at higher temperatures. We then asked, “What temperatures would we have to reach such that when we inject any given fuel of choice, it would ignite right away the way diesel does at typical engine operating temperatures?”

The answer is of course dependent on the chosen fuel. For example, alcohol fuels like methanol and ethanol only require that intake temperatures be about 50 °C to 60 °C higher than in conventional diesel engines to produce the right conditions to behave like diesel fuel and readily auto-ignite upon fuel injection. More auto-ignition resistant fuels such as hydrogen or ammonia require slightly higher temperatures, but the principle of “fuel flexibility at high enough temperature” remains.

To build a fuel-adaptable engine platform, we begin with an existing diesel engine platform and make modifications.

The first change is the fuel system, using compatible materials and adjusting for any difference in volumetric energy density. For example, it takes 2.3 times as much methanol to reach the same fuel energy as diesel, and thus the fuel injection must be 2.3 times larger. For ethanol that ratio is 1.7 times.

We also add some surface treatments and our own engine control unit to take greater advantage of the benefits of the cleaner-burning fuels we use; for instance, we optimize for low engine-out nitrogen oxides (NOx) in the absence of soot formation. We’ve shown a 10 times reduction in engine-out NOx from production diesel calibrations without forming soot or losing efficiency.

That temperature increase to promote rapid auto-ignition of any chosen fuel is accomplished by utilizing the energy already available in the engine and redirecting it. The diesel engine’s compressor produces hot compressed air; typically, that air is cooled in the charge air cooler (CAC). We can redirect the hot air from the compressor and bypass the CAC directly to the intake port. We can also remove the exhaust gas recirculation cooler to enable use of hot combustion products. These changes provide sufficient thermal energy to operate the entire engine map on any fuel. To start the engine, we need an initial heat source, such as intake grid heaters, glow plugs, or other start aids typically used on diesel engines in cold weather to heat the air for the first few cycles.

These changes allow a diesel platform to operate on any fuel while achieving performance identical to the base diesel engine—an identical torque curve—not “diesel-like” but still with sacrifices relative to diesel, or de-rated at low engine speed like spark-ignition strategies. The non-premixed nature of combustion preserves the ability to deliver the low-speed torque that users have come to rely upon from their engines.

Become a Member: How to Join ASME

The emissions profile is significantly different, however. Fuels like ethanol, methanol, ammonia, and other small-molecule alternative fuels don’t form appreciable soot even when burned in a non-premixed manner. In fact, engine-out soot emissions are only one-tenth of the EPA tailpipe limit, meaning the engine can meet soot regulations without a diesel particulate filter. Further, by starting with low-soot fuels, the engine can be calibrated to avoid the usual trade-off between soot formation and NOx. Finally, and perhaps most importantly in the current climate crisis, these fuels can be sourced from renewable sources to drastically reduce GHG emissions.

The result is an engine that acts like a diesel in every way except for the fuel you put into it and the lower criteria emissions and lower greenhouse gases coming out. The solution scales the same way the diesel cycle does and works well even in engines with large bore sizes, which are often the engines in the hardest-to-electrify applications.

We’ve retrofitted four diesel trucks (plus one genset) to operate on alcohol fuel and are driving them through demanding road tests, including regularly pulling 80,000-pound gross vehicle weight. The vehicles have a range of over 1,000 miles, and for liquid fuels like alcohols, installing refueling infrastructure along key fleet routes is very simple. Any of the quarter million diesel mechanics in the country can work on these vehicles, and because we are making minor changes to traditional parts, we can leverage existing supply chains and integrate this solution either as a new OEM build or as a retrofit.

Across the complete lifecycle

Given the technology is compatible with any fuel, it is time to ask: What factors should be considered when selecting a fuel?

One obvious factor is that it should be low carbon—specifically low greenhouse gas on a lifecycle basis, in contrast to looking only at tailpipe emissions. The complete lifecycle framework is key here. The atmosphere can be thought of as a “giant joint checking account,” where the net of deposits and withdrawals of greenhouse gases affect the balance rather than any single transaction.

Comprehensive lifecycle analyses, such as those conducted by David L. MacIntosh of Harvard University or underpinning Argonne National Laboratory’s GREET model (an open-source lifecycle analysis tool for energy and transportation), show that decarbonized fuels and biofuels have very low carbon intensities.

There are other important considerations as well. The fuel should be low-cost, energy-dense, already at scale, and readily available. Across different applications in different locations, no single fuel may be the best choice. Still, it is essential to think about these attributes more holistically than is customary today.

The first factor our customers ask us about is cost. Operating costs will always depend on how much an alternative fuel costs and how efficiently the engine can use it. Since fuels differ widely in their energy density, units of volume aren’t the best way to do an “apples to apples” comparison among fuels. For example, when we show our trucks, people always ask us about the miles per gallon, but the cost per mile is actually what people are trying to understand.

Consuming more gallons of a lower energy density fuel (like ethanol) does not mean higher costs, and fuels like ethanol are lower cost on an energy basis than diesel fuel. That means you can purchase 1.7 gallons of ethanol (the ratio of energy densities) for less than you can purchase a single gallon of diesel.

Even with the energy-density penalty, ethanol provides a 30 cent per mile savings over diesel fuel in a semi-truck, providing very compelling economics for fleet operators. And given the low capital cost of engine technology and liquid alternative fuel infrastructure, this per-mile cost savings also leads to a lower total cost of ownership than for diesel vehicles.

Availability is typically the second question customers ask about, which is usually a function of fueling infrastructure. In contrast to passenger cars, refueling of diesel-powered heavy equipment is more frequently done independently, where a farm, fleet, or mining operation takes delivery from fuel wholesalers to refuel onsite rather than driving to a retail station. This allows many end-use operations much more autonomy to adopt an alternative fuel, even if retail availability may be initially limited.

In the U.S., almost every wholesale fuel terminal in the country offers three fuels: gasoline, diesel, and ethanol. As a result, taking delivery of a tankerful of ethanol is as easy as taking delivery of diesel fuel today, and future fuels can be distributed to customers in a similar fashion. That simplicity can ease the transition to low-carbon liquid fuels.

Another question customers ask is, “How much of that fuel is there?” That gets to the issue of scale and scalability. Scale determines how much climate impact and market relevance a fuel has today. There is a near-term opportunity in the U.S. to use ethanol, due to its multi-decade head start from U.S. investments in ethanol production. Long-term and globally, methanol, ammonia, or other energy carriers are likely to emerge as fuels of choice due to their scalability, which determines the fuel’s maximum potential decarbonization potential.

Scale and scalability must also be considered when evaluating greenhouse gas benefits, and carbon intensity figures should be coupled with information on the present and future scalability of that fuel to accurately assess its true decarbonization potential.

Another consideration of scalability is what other applications might be competing for that fuel. For example, renewable diesel has some attractive properties, but the production of sustainable aviation fuel is poised to dominate the demand for the lipid-based feedstocks that renewable diesel production requires. It also takes five times as many acres to grow crops for lipids as it does to grow the feedstock to make the energy equivalent of alcohol.

A both/and attitude

Based on our research, we have concluded that alcohols are the best alternative fuels when considering the range of factors that impact customer needs and climate goals. They are liquids under ambient conditions, making storage and dispensing easy. They are simple molecules that can be made or synthesized from a variety of feedstocks, in contrast to larger molecules like those in diesel or gasoline.

As a result, they are abundant, low-cost, and low-carbon. For example, ethanol in the U.S. is lower carbon than diesel by 45 percent on a lifecycle basis, even coming in lower than grid-average electricity.

But different applications currently reliant on diesel fuel may weigh the benefits differently. Our engine needs to accommodate applications where another alternative would best serve the customer, such as if a fleet had a preference for synthetic gasoline to have an immediate drop-in that was also compatible with new vehicles.

You Might Also Enjoy: Energy Blog: Twilight for ICE Vehicles?

Providing a solution with component-level changes allows for retrofitting of existing vehicles as well as new, allowing multiple options to integrate into existing operations. Because we aren’t hitched to any single fuel, our technology and our customers have the potential to adapt to current conditions and future developments.

That potential flexibility is perhaps the greatest benefit of having an engine that can ignite a wide range of fuels. We have preserved the underlying architecture of the diesel engine, and by making changes at the component level we have liberated the engine from its need to operate on petroleum-derived fuels. The progress we have made is exciting: We’ve run our engine back-to-back days on ethanol, methanol, hydrous ethanol, and E85.

It's too easy to look at the push to electrify transportation and conclude that no other alternatives are needed, or that pursuing alternatives in parallel will somehow diminish electrification. I believe that way of thinking is missing the massive scale of the challenge we face. We need a “both/and” attitude.

Low-cost and simple-to-adopt solutions to free diesel engines from petroleum dependence will enable internal combustion engines to lead the way in near-term decarbonization, while continuing to scale and dominate heavy-duty applications. By taking a multi-pronged approach and complementing electrification, the overall rate of decarbonization will be faster than any single technology could accomplish.

Julie Blumreiter is co-founder and chief technology officer at ClearFlame Engine Technologies, based in Geneva, Ill. Her article was adapted from a presentation Blumreiter gave at the ASME ICE Forward Conference in October 2022.

.png?width=854&height=480&ext=.png)