A Dye-removing Polymer That Cleans Water

A Dye-removing Polymer That Cleans Water

Industrial dyes soil our waterways. Now there’s a polymer that can take them out—and it can be recovered and reused repeatedly.

The delight elicited by the stripes and prints and polka dots on our shirts and skirts and flags and sheets we owe to the availability and diversity of industrial dyes. But when those same dyes are not on our textiles, but in our waterways, they become less of a delight and more of an environmental liability. They block light for aquatic plants, are toxic for humans and other animals, and have been shown to be both allergenic and carcinogenic.

“So there is a need—an unmet need—to address this problem,” said Januka Budhathoki-Uprety, a professor of fiber and polymer science in the department of textile engineering, chemistry and science at North Carolina State University. And meet this need she has. Budhathoki-Uprety and her colleagues have created a polymer that, when mixed with dye contaminated water, latches on to dyes, effectively removing them from the water. What’s more, subsequent to performing this seeming magic trick, the polymer can be completely recovered, ready to be used again.

More Like This: Three Advancements In Water Purification

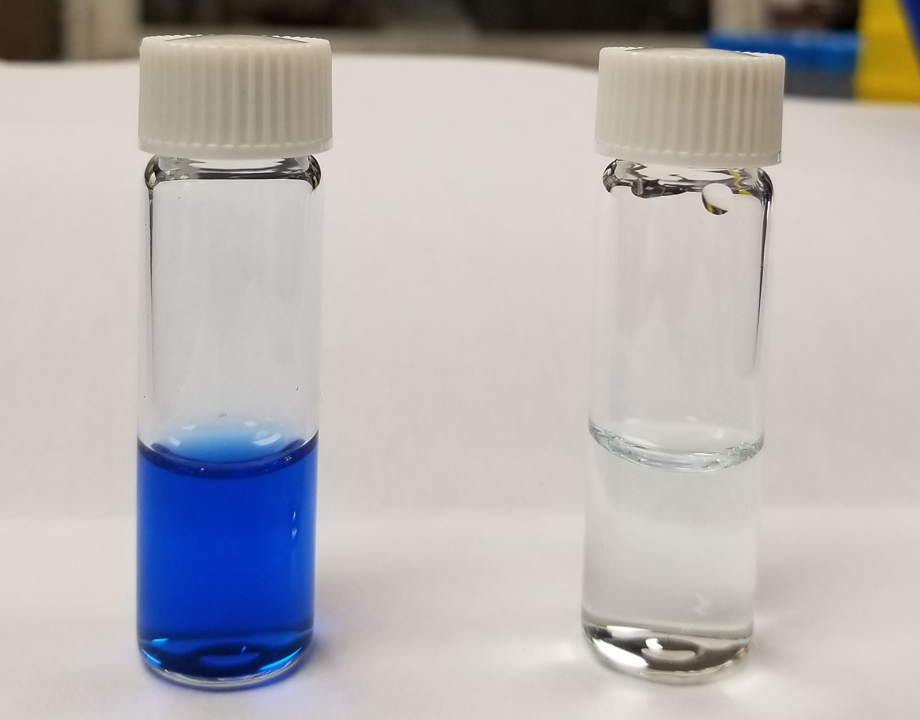

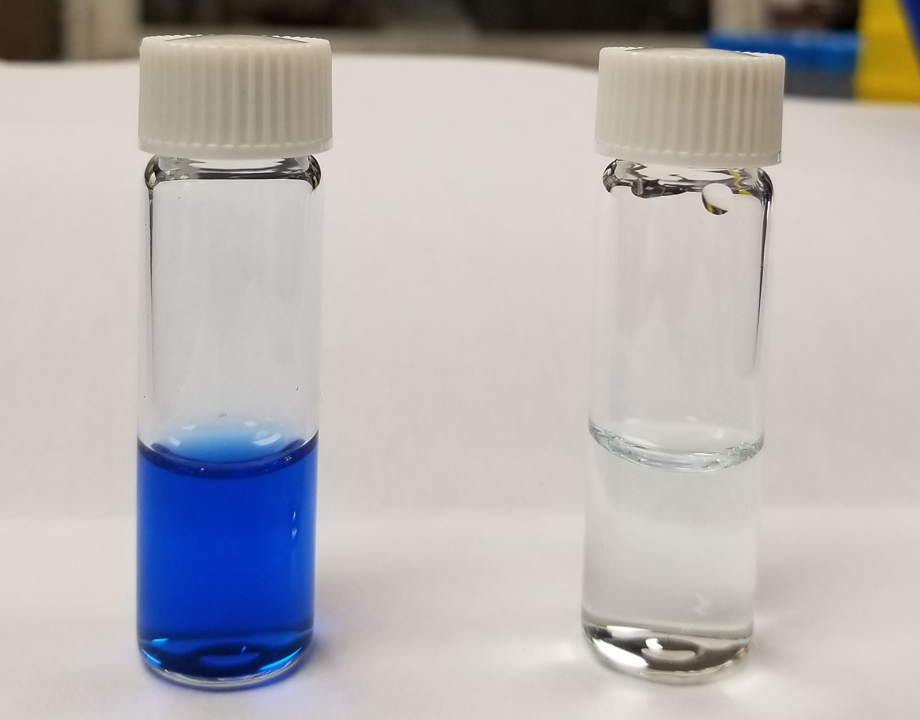

Budhathoki-Uprety found that modifying the pH of a polycarbodiimide allows it to attract the specific class of dyes that she was looking at. The polymer is not water soluble and is dissolved in an organic solvent, while the dyes are in an aqueous solution. That means that, like oil and water, they don’t mix, and to connect the polymer with the dyes there has to be some mechanical agitation. In the lab, this meant some vortex mixing. In industry, it could mean controlled mixing before waste.

exits a factory.

But this oil and water property comes with a distinct advantage: once the polymer has sucked all the dye from a sample of water, the polymer and the now clean water stay separate. The polymer-bound dye can literally be poured off like schmaltz from a fat separator.

Related Content: Cleaning Up Industrial Water

Then, by re-tweaking the pH, the dye can be separated from the polymer. The recovered polymer can be used again to remove additional dye. And the dye, too, could be used again, rather than wasted. “As long as the dye doesn’t break down in the acid-based treatment, we can reuse it,” said Budhathoki-Uprety. The polymer is derived from petroleum, but as it can be completely recouped and used over and over again, the technique is essentially sustainable.

The paper that elucidated the new process, “Polycarbodiimide for Textile Dye Removal from Contaminated Water,” which appeared in Applied Polymer Materials this July, looked at a narrow class of dyes. But the polymer Budhathoki-Uprety used—and others—could be modified to work with a broader range of dyes. She is right now working on expanding that library of polymers. And there’s every reason to think that similar methods could be used to remove pharmaceuticals and other contaminants from wastewater and other effluvia. “A lot of these polymers can be versatile and can be tuned,” said Budhathoki-Uprety.

Read Further: Shocking Purity

Already a number of representatives from the dye and textile industries have reached out to Budhathoki-Uprety, hoping to put her solution to use as soon as possible. But before polymers start mixing with the waste streams of the world to remove dyes and other pollutants, the most pressing issue is scale and cost. “At the moment it’s still expensive” explains Budhathoki-Uprety. “At the research level it can be done. Now comes the engineering aspect, to scale up, to make it cheaper, and to make it viable.”

Michael Abrams is a technology writer based in Westfield, NJ.