5 Digital Twins Applications That Could Solve the Future’s Problems

5 Digital Twins Applications That Could Solve the Future’s Problems

Virtual replicas of our most complicated systems of systems may soon help simplify how we work them.

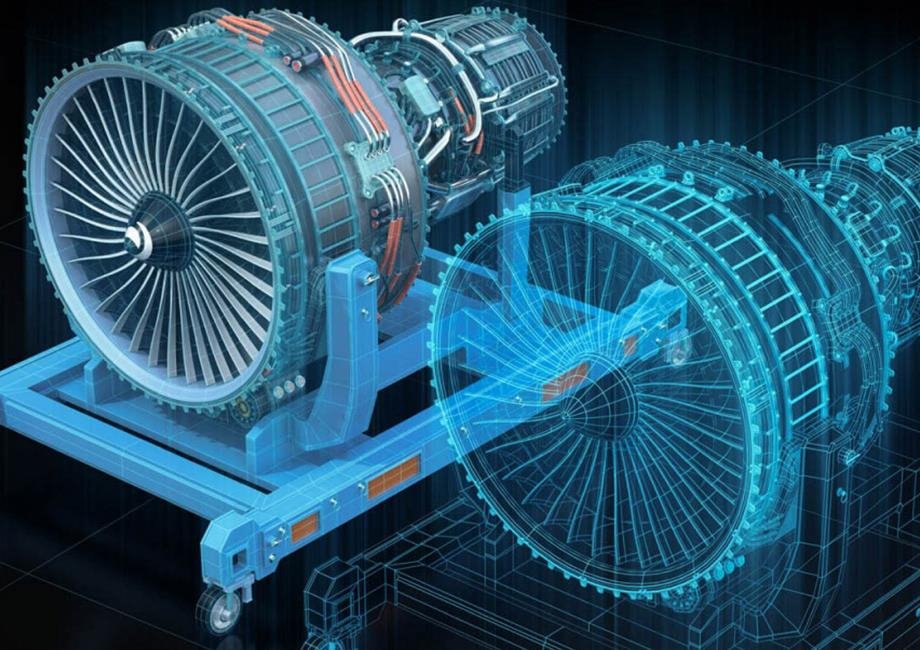

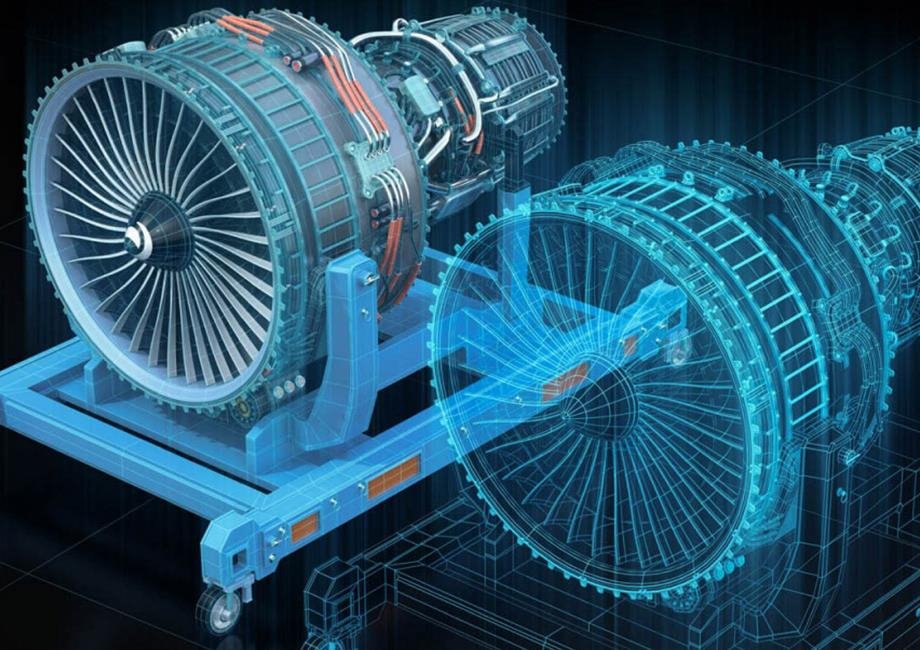

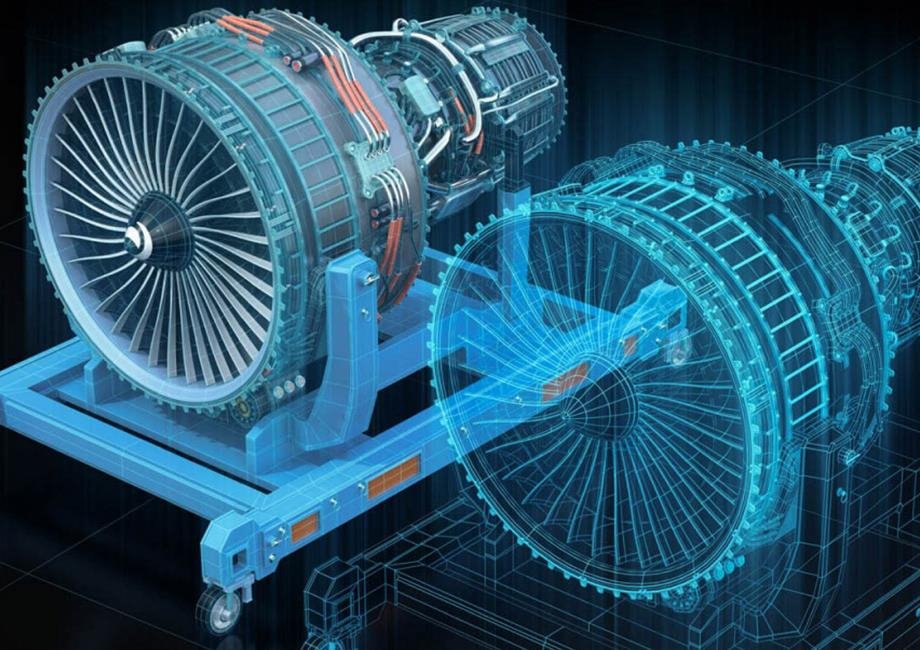

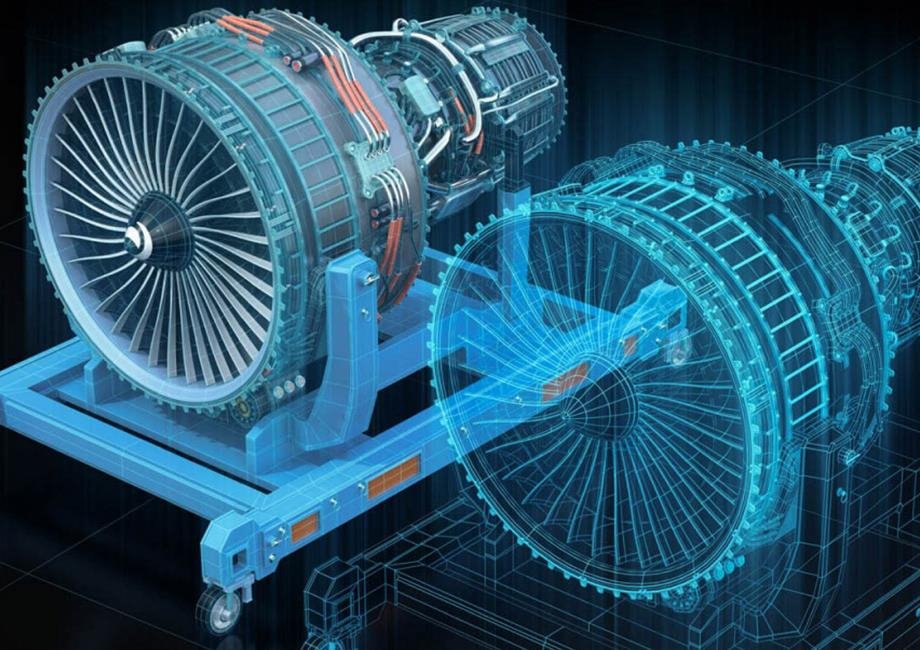

What is a digital twin? Take a system, fill it with sensors, then use the data to power a model that can tell you exactly what is going on in the system—and perhaps how to make it better.

A more precise definition is tough, as the size and nature of twins in different fields are so disparate. “What I’ve seen is that there are almost as many ideas of what a digital twin is, as there are researchers,” said Shane O’Seasnáin, a professor of mechanical engineering at the Eindhoven University of Technology in the Netherlands. “There are good reasons for that: Usually people focus in on one area of research, so they build the digital twin for their use case.”

Zheng O’Neil, a professor of mechanical engineering at Texas A&M, and a member of the university’s Digital Twin Lab, puts it another way: “It’s a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity,” she said. “With the rapid development of sensing, communication, and computing technologies, digital twins have been developed and used to simulate real-world conditions with real-time data, improve operations, and enable optimizations at various scales.”

Become an ASME Member Today

However you define it, the digital twin is a concept sweeping the engineering world. When systems get complex, there’s no better tool for understanding interactions and making predictions. Here are five areas soon to be revolutionized by the digital twin.

There are a lot of buildings in the world and each one is a tangle of systems and subsystems. Understanding exactly how electricity, plumbing, heating, cooling, foot traffic, elevators, work schedules, and cleaning schedules work together—and sometimes against each other—to keep a building functioning will naturally give rise to greater efficiency, comfort, and design.

“We use a simulation to provide either/or scenarios for analysis for building owners and designers,” said O’Neil. “But we’re not just using the models at the design stage, we’re trying to use those models across the entire lifecycle of the building.”

With thousands of sensors in a building, the model can produce more efficient solutions than a human operator can envision. For instance, when the temperature is at a comfortable level for the occupants of a building, a building manager without a digital twin might assume everything is A-OK while in fact, there could be significant waste.

“If the room temperature is maintained perfectly, you won’t observe something we call simultaneous heating and cooling,” said O’Neil. “Facility mangers may not notice it—until they receive the bill.” The digital twin will offer suggestions, and the owners and managers can then best decide how to fix the problem.

Similarly, during cold and flu season, the digital twin can suggest ways of placing people in the building to maximize space between them. Alternatively, during a period where, say, heating might be expensive, the digital twin can suggest bringing people together.

Digital twin solutions, such as Johnson Corporations’ OpenBlue, Microsoft’s Azure, and Honeywell’s Honeywell Forge are soon to be at work in smart buildings worldwide.

There’s hardly a more complicated entity on the planet than the city. It's a web of traffic and pedestrian pattens, and subways and waterways, to say nothing of power plants and power usage, influx and exodus, food supplies and demographics. There are specialized civil engineers for each of those areas, of course, but a digital twin can offer new insights and illuminate connections that have never before been conceived.

“You can combine different types of systems—and users—together and really see what are the emergent effects that come out of all of this,” said O’Seasnáin. “Maybe we can look at the water table, we can look at pollution, we can look at individual behavior, we can look at things like obesity and diabetes, we can look at green spaces—we can look at all sorts of areas and we can really take things a step further and make better decisions.”

Dassault Systemes is working with the city of Rennes, France, to create a digital twin. A virtual, 3D model that you can practically virtually walk through will allow city planners and businesses to make sophisticated decisions about development, infrastructure, and travel.

More on Digital Engineering: Training the Future Engineering Workforce

With water and temperature management crucial to survival, Singapore is leading the way with their Virtual Singapore digital twin. It already has three million street-level photos, 160,000 aerial photos, and billions and data points built into its 100-terabyte virtual city. Many of the world’s cities—Helsinki, Shanghai, New York, to name a few—are following suit.

Digital twins have a place far outside the city as well. A farm is a system like any other, with an increasing amount of automation and dependent on a host of ever-changing variables. Moisture and soil sensors in the field, livestock monitors in the barn, supply chain information, and data on machinery can all be fed into a single model. With an eye on digital twin software on a phone or computer, farmers can make decisions without relying on direct observation. Depending on their level of automation, they can also change plans from the comfort of their screen.

Jacob van den Borne, a potato farmer in the Netherlands, is building just such a digital twin of his operation in Reusel.

“His grandfather used to walk his farm and with a little notebook and say, ‘OK, it’s wet here, and it’s dry there, and the grass grows higher here, and the weeds better there,’” said O’Seasnáin. “And so, in a way, he was building, conceptually, a kind of twin, except he didn’t have the software.” Now van den Borne has the software, and the drones, and the sensors, to make his farm as streamlined and efficient as possible.

Potatoes, needless to say, are not the only crop that can benefit from a twin. Researchers at the Texas A&M Agrilife Center in Corpus Christi are creating a digital twin for cotton farming to help farmers navigate the balance between crop growth and fiber quality. Similarly, the AI Institute for Resilient Agriculture at Iowa State University is creating “AI-driven, predictive digital twins,” for better resource management. They hope it will help farms use water, fertilizers, and energy with ultra-precision and efficiency, which, in the end, helps both the farmer and the environment.

The purpose of the digital twin, for facilities smaller than a city—like a nuclear power plant—is simpler. “I like to keep it in the space of operations and maintenance,” said Richard Vilim, a senior nuclear engineer who manages plant analysis and control and the sensors department at Argonne National Laboratory in Illinois. He’s also developing digital twins for use with reactors. “It’s a parallel construct to determine if things are going well. Or, if something’s going wrong, what’s going wrong.”

The sensors and data processing that go into the kind of twin Vilim is working on have a focused purpose: make maintenance more efficient and cheaper. For example, the pump in a nuclear power plant is taken apart and put back together every five years, regardless of its state of health.

“What you want to do is deferred maintenance,” said Vilim. “The digital twin is a reference you can compare a component or system against to tell if your system is going south. And if it’s not, then that’s the basis for deferred maintenance.”

Vilim is working to create digital twins for the existing fleet of reactors as well as for companies like X-Energy, that are creating small modular reactors. Where multiple reactors have the same design, they can use the same digital twin model.

More Uses of Digital Twins: 10 Smartest Cities of 2023

“We’d like to go to semi-autonomous power plants,” said Vilim. “The big problem with nuclear plants is that there are a lot of people there. So if you can move these human tasks to the computer, there’s cost savings, because the computer can be remotely located, and it can handle a number of plants. You know, you can’t take the person, clone them, and move them to different plants.”

If digital twins have a place solving problems with living-organism-like entitles such as buildings and cities, they probably have a place with living organisms as well. Already the Living Heart Project and the Living Brain Project are creating little pieces of what may one day be a Human Digital Twin.

The hard part, though, is not creating a single integrated model of the many systems of a generic human body but building a model that is specific to each patient. This, of course, will require a quantity of health sensors far beyond the Apple Watch. But, with such a tool, doctors and patients may be able to examine complex interactions, make better diagnoses, and better weigh risks, than they do now.

“Your doctor will be in the room, but your digital twin will be there too. And you’ll be able to maybe visualize it as a dial. They’ll say okay, this is you today. Turn the dial back, that was you five years ago. Go the other way, this is you in five years,” said O’Seasnáin. “And I think that’s a fascinating way that twins will really help with health and medicine in the future.”

Michael Abrams is a science and technology writer in Westfield, N.J.

A more precise definition is tough, as the size and nature of twins in different fields are so disparate. “What I’ve seen is that there are almost as many ideas of what a digital twin is, as there are researchers,” said Shane O’Seasnáin, a professor of mechanical engineering at the Eindhoven University of Technology in the Netherlands. “There are good reasons for that: Usually people focus in on one area of research, so they build the digital twin for their use case.”

Zheng O’Neil, a professor of mechanical engineering at Texas A&M, and a member of the university’s Digital Twin Lab, puts it another way: “It’s a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity,” she said. “With the rapid development of sensing, communication, and computing technologies, digital twins have been developed and used to simulate real-world conditions with real-time data, improve operations, and enable optimizations at various scales.”

Become an ASME Member Today

However you define it, the digital twin is a concept sweeping the engineering world. When systems get complex, there’s no better tool for understanding interactions and making predictions. Here are five areas soon to be revolutionized by the digital twin.

Buildings

There are a lot of buildings in the world and each one is a tangle of systems and subsystems. Understanding exactly how electricity, plumbing, heating, cooling, foot traffic, elevators, work schedules, and cleaning schedules work together—and sometimes against each other—to keep a building functioning will naturally give rise to greater efficiency, comfort, and design.

“We use a simulation to provide either/or scenarios for analysis for building owners and designers,” said O’Neil. “But we’re not just using the models at the design stage, we’re trying to use those models across the entire lifecycle of the building.”

With thousands of sensors in a building, the model can produce more efficient solutions than a human operator can envision. For instance, when the temperature is at a comfortable level for the occupants of a building, a building manager without a digital twin might assume everything is A-OK while in fact, there could be significant waste.

“If the room temperature is maintained perfectly, you won’t observe something we call simultaneous heating and cooling,” said O’Neil. “Facility mangers may not notice it—until they receive the bill.” The digital twin will offer suggestions, and the owners and managers can then best decide how to fix the problem.

Similarly, during cold and flu season, the digital twin can suggest ways of placing people in the building to maximize space between them. Alternatively, during a period where, say, heating might be expensive, the digital twin can suggest bringing people together.

Digital twin solutions, such as Johnson Corporations’ OpenBlue, Microsoft’s Azure, and Honeywell’s Honeywell Forge are soon to be at work in smart buildings worldwide.

Cities

There’s hardly a more complicated entity on the planet than the city. It's a web of traffic and pedestrian pattens, and subways and waterways, to say nothing of power plants and power usage, influx and exodus, food supplies and demographics. There are specialized civil engineers for each of those areas, of course, but a digital twin can offer new insights and illuminate connections that have never before been conceived.

“You can combine different types of systems—and users—together and really see what are the emergent effects that come out of all of this,” said O’Seasnáin. “Maybe we can look at the water table, we can look at pollution, we can look at individual behavior, we can look at things like obesity and diabetes, we can look at green spaces—we can look at all sorts of areas and we can really take things a step further and make better decisions.”

Dassault Systemes is working with the city of Rennes, France, to create a digital twin. A virtual, 3D model that you can practically virtually walk through will allow city planners and businesses to make sophisticated decisions about development, infrastructure, and travel.

More on Digital Engineering: Training the Future Engineering Workforce

With water and temperature management crucial to survival, Singapore is leading the way with their Virtual Singapore digital twin. It already has three million street-level photos, 160,000 aerial photos, and billions and data points built into its 100-terabyte virtual city. Many of the world’s cities—Helsinki, Shanghai, New York, to name a few—are following suit.

Farms

Digital twins have a place far outside the city as well. A farm is a system like any other, with an increasing amount of automation and dependent on a host of ever-changing variables. Moisture and soil sensors in the field, livestock monitors in the barn, supply chain information, and data on machinery can all be fed into a single model. With an eye on digital twin software on a phone or computer, farmers can make decisions without relying on direct observation. Depending on their level of automation, they can also change plans from the comfort of their screen.

Jacob van den Borne, a potato farmer in the Netherlands, is building just such a digital twin of his operation in Reusel.

“His grandfather used to walk his farm and with a little notebook and say, ‘OK, it’s wet here, and it’s dry there, and the grass grows higher here, and the weeds better there,’” said O’Seasnáin. “And so, in a way, he was building, conceptually, a kind of twin, except he didn’t have the software.” Now van den Borne has the software, and the drones, and the sensors, to make his farm as streamlined and efficient as possible.

Potatoes, needless to say, are not the only crop that can benefit from a twin. Researchers at the Texas A&M Agrilife Center in Corpus Christi are creating a digital twin for cotton farming to help farmers navigate the balance between crop growth and fiber quality. Similarly, the AI Institute for Resilient Agriculture at Iowa State University is creating “AI-driven, predictive digital twins,” for better resource management. They hope it will help farms use water, fertilizers, and energy with ultra-precision and efficiency, which, in the end, helps both the farmer and the environment.

Power Plants

The purpose of the digital twin, for facilities smaller than a city—like a nuclear power plant—is simpler. “I like to keep it in the space of operations and maintenance,” said Richard Vilim, a senior nuclear engineer who manages plant analysis and control and the sensors department at Argonne National Laboratory in Illinois. He’s also developing digital twins for use with reactors. “It’s a parallel construct to determine if things are going well. Or, if something’s going wrong, what’s going wrong.”

The sensors and data processing that go into the kind of twin Vilim is working on have a focused purpose: make maintenance more efficient and cheaper. For example, the pump in a nuclear power plant is taken apart and put back together every five years, regardless of its state of health.

“What you want to do is deferred maintenance,” said Vilim. “The digital twin is a reference you can compare a component or system against to tell if your system is going south. And if it’s not, then that’s the basis for deferred maintenance.”

Vilim is working to create digital twins for the existing fleet of reactors as well as for companies like X-Energy, that are creating small modular reactors. Where multiple reactors have the same design, they can use the same digital twin model.

More Uses of Digital Twins: 10 Smartest Cities of 2023

“We’d like to go to semi-autonomous power plants,” said Vilim. “The big problem with nuclear plants is that there are a lot of people there. So if you can move these human tasks to the computer, there’s cost savings, because the computer can be remotely located, and it can handle a number of plants. You know, you can’t take the person, clone them, and move them to different plants.”

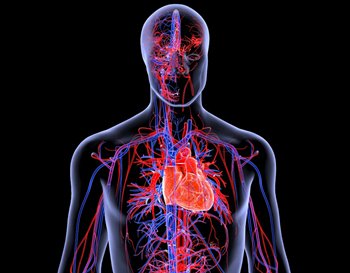

People

If digital twins have a place solving problems with living-organism-like entitles such as buildings and cities, they probably have a place with living organisms as well. Already the Living Heart Project and the Living Brain Project are creating little pieces of what may one day be a Human Digital Twin.

The hard part, though, is not creating a single integrated model of the many systems of a generic human body but building a model that is specific to each patient. This, of course, will require a quantity of health sensors far beyond the Apple Watch. But, with such a tool, doctors and patients may be able to examine complex interactions, make better diagnoses, and better weigh risks, than they do now.

“Your doctor will be in the room, but your digital twin will be there too. And you’ll be able to maybe visualize it as a dial. They’ll say okay, this is you today. Turn the dial back, that was you five years ago. Go the other way, this is you in five years,” said O’Seasnáin. “And I think that’s a fascinating way that twins will really help with health and medicine in the future.”

Michael Abrams is a science and technology writer in Westfield, N.J.