Design for Additive Manufacturing with Metals Case Studies Package

Course Type:

Course Number:

Credits:

Language:

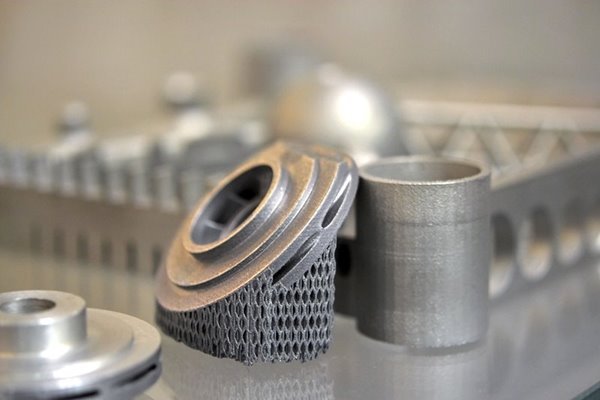

Apply Additive Manufacturing design concepts with three common AM case studies: Replication, Adaptation, and Optimization.

Buying for a Group?

Get 5 seats or more for any Learning Path and save 25%. (This cannot be combined with any other offer; excludes Codes & Courses Packages).

This Standard was last reviewed and reaffirmed in {{activeProduct.ReaffirmationYear}}. Therefore this version remains in effect.

{{activeProduct.Title}}

Digital products are restricted to one per purchase.

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPrice) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPriceSale) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPrice) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.ListPriceSale) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.MemberPrice) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

{{activeProduct.CurrencySymbol}}{{ formatPrice(activeProduct.MemberPriceSale) }} was {{activeProduct.CurrencySymbol}}{{ formatPrice(originalPrice) }}

*Excluding Lite Members

Final invoices will include applicable sales and use tax.

Print or Share

Sorry, we only have available spots for this course. Would you like to add those to your cart?