Why It’s Time to Unify ECAD and MCAD

Why It’s Time to Unify ECAD and MCAD

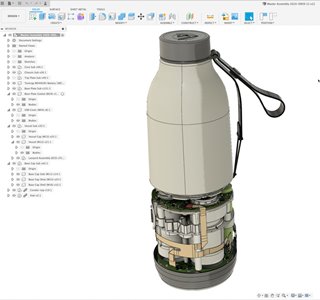

Fusion 360 fosters collaboration between electrical and mechanical engineers by unifying both ECAD and MCAD design tools in a single platform.

In today’s cloud-connected world, it would be reasonable to expect design tools would have overcome the long-standing collaboration challenges that electronics and mechanical designers often face. Yet, most development teams still struggle to rely on manual methods, such as emails and exchanging files, to overcome such a complex task. Many designers spend enormous time and effort, simply managing separate ECAD and MCAD design tools. Hours are wasted trying to get disparate design systems to exchange accurate design data—data that needs to be transferred, translated, and verified with every push and pull.

Add to these administrative tasks the fact that designs themselves have become more challenging with the ever-shrinking product design real estate. Smaller, denser, and low power devices pose another level of challenges that require integration between the electrical and mechanical domains, unlike anything we’ve ever seen before. Not to mention the pressure designers and project managers are facing to deliver products faster, with more features, and at a lower cost.

“The integration of mechanical and electrical is traditionally very challenging, you have two very siloed teams, so when it is time to integrate these two systems, you have a lot of problems,” said Mark Lyons, Vice President of Engineering at LifeFuels.

As product development changes, electronics design needs to follow. Engineers need to start seeing our PCB designs from a broader perspective, in a 3D world, as part of a complete product development workflow. There are three main reasons why every electronics designer needs to have a single ECAD - MCAD tool to prepare for these changes:

Electronic designers continue to experience an industry of fragmented and disconnected toolsets – tools that were designed with specific design challenges in mind and are good at tackling individual, discrete sets of problems (ECAD and MCAD). The burden should not be put on designers to step out of their CAD design environment into an unfamiliar setting and learn new tools.

Learn More About: Why It’s Time to Embrace the Cloud in Design and Engineering

The role of software management can unify engineers by bringing together different design elements into one platform. A software platform like Fusion 360—a cloud-based, 3D CAD, CAM, CAE, and PCB, all in one tool—addresses many of the problems electronic designers face today and will face, increasingly, in the future. If you’re doing any product development, this is the world that you’ll live in. Here are some examples of how software like Fusion 360 can assist engineers.

“Fusion 360 had allowed our mechanical engineers and electrical engineers to work together in a collaborative way, to fit everything into the small space of our bottle,” Hubler said.

Take Our Latest Quiz: The History of Computer-Aided Design

In the past, electronic designers were typically left outside of the product development process in 3D CAD. The question was always the same: how do you bring the 2D world of electronics into a 3D world? New software platforms that can manage different design files don’t simply provide a solution to this integration problem but instead resolves the problem by making the ECAD tool the MCAD tool. Both disciplines – electronics and mechanical – are supported by the same tool: a single, unified platform uses a single dataset. Finally, electronics engineers can design in a new dimension (pun intended).

Fusion 360 enables ECAD and MCAD designers to work natively and independently on the same design project within the same design management platform. This enables engineers and teams to share:

For engineers, a software platform like Fusion 360 offers a connected experience for PCB, Mechanical, and overall product design, ensuring every stakeholder is part of the product development cycle. With one cloud-based data management — powered by Amazon Web Services technology for secure storage and infinite computing power — a collaboration between all stakeholders becomes an integral part of the design process in Fusion 360.

This ensures change is seamlessly managed, be it revisions, board shape updates, component moves, library updates, or enclosure changes. This means:

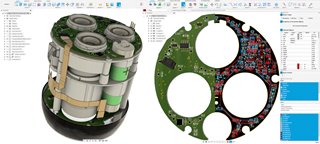

With both ECAD and MCAD working on the same Fusion 360 environment with one dataset, 3D PCB data such as board copper, core material, and components can be analyzed, verified, and validated on the MCAD side to ensure they meet product design specifications, including:

Engineers can now access comprehensive electronics and PCB design tools in one product development platform. Converge your ECAD and MCAD workflows for unified electronics design so you can engineer, design, and make anything.

To find out more about how Fusion 360 can help your team achieve the new possible, visit Autodesk.

Add to these administrative tasks the fact that designs themselves have become more challenging with the ever-shrinking product design real estate. Smaller, denser, and low power devices pose another level of challenges that require integration between the electrical and mechanical domains, unlike anything we’ve ever seen before. Not to mention the pressure designers and project managers are facing to deliver products faster, with more features, and at a lower cost.

“The integration of mechanical and electrical is traditionally very challenging, you have two very siloed teams, so when it is time to integrate these two systems, you have a lot of problems,” said Mark Lyons, Vice President of Engineering at LifeFuels.

As product development changes, electronics design needs to follow. Engineers need to start seeing our PCB designs from a broader perspective, in a 3D world, as part of a complete product development workflow. There are three main reasons why every electronics designer needs to have a single ECAD - MCAD tool to prepare for these changes:

- Collaboration is now a necessity. Today’s design process is anything but linear. Component availability changes, board layouts need to shift to fit enclosures at the last minute. Not having a way to understand how your product affect your PCB design process is handicapping your capabilities.

- File formats are a burden. Putting your design in a box as a file format naturally lends itself to errors in translation. When was the last time your STEP file fully communicated your design intent? Probably never. No longer should hours be spent on documentation to supplement what should already be communicated in our design.

- The future is blending disciplines. Engineers are expected to do it all; documentation, emails, design, sourcing — you name it. Mechanical design is now being added to this list as our needs for smart devices deepens. And have you seen molded interconnect devices (MIDs)? You won’t be designing those boards only in 2D.

Software Can Unify Engineering Disciplines

Electronic designers continue to experience an industry of fragmented and disconnected toolsets – tools that were designed with specific design challenges in mind and are good at tackling individual, discrete sets of problems (ECAD and MCAD). The burden should not be put on designers to step out of their CAD design environment into an unfamiliar setting and learn new tools.

Learn More About: Why It’s Time to Embrace the Cloud in Design and Engineering

The role of software management can unify engineers by bringing together different design elements into one platform. A software platform like Fusion 360—a cloud-based, 3D CAD, CAM, CAE, and PCB, all in one tool—addresses many of the problems electronic designers face today and will face, increasingly, in the future. If you’re doing any product development, this is the world that you’ll live in. Here are some examples of how software like Fusion 360 can assist engineers.

- ECAD/MCAD Co-Design. The cloud-based design environment allows all engineers to quickly iterate ideas and bring function and form together on any device.

- Simulate. Engineers can test fit and motion, perform simulations, and generate realistic renderings all in the same tool.

- CAM. When it’s time for production, it’s easy to create toolpaths for CNC machining or additive manufacturing

“Fusion 360 had allowed our mechanical engineers and electrical engineers to work together in a collaborative way, to fit everything into the small space of our bottle,” Hubler said.

Take Our Latest Quiz: The History of Computer-Aided Design

In the past, electronic designers were typically left outside of the product development process in 3D CAD. The question was always the same: how do you bring the 2D world of electronics into a 3D world? New software platforms that can manage different design files don’t simply provide a solution to this integration problem but instead resolves the problem by making the ECAD tool the MCAD tool. Both disciplines – electronics and mechanical – are supported by the same tool: a single, unified platform uses a single dataset. Finally, electronics engineers can design in a new dimension (pun intended).

Design Unification

Fusion 360 enables ECAD and MCAD designers to work natively and independently on the same design project within the same design management platform. This enables engineers and teams to share:

- One common design environment

- One common design management system

- One design dataset with no file exchange, export, or third-party integration ever needed

Ultimate ECAD/MCAD Collaboration

For engineers, a software platform like Fusion 360 offers a connected experience for PCB, Mechanical, and overall product design, ensuring every stakeholder is part of the product development cycle. With one cloud-based data management — powered by Amazon Web Services technology for secure storage and infinite computing power — a collaboration between all stakeholders becomes an integral part of the design process in Fusion 360.

This ensures change is seamlessly managed, be it revisions, board shape updates, component moves, library updates, or enclosure changes. This means:

- Real-time ECAD-MCAD collaboration

- Design changes can be fluidly passed and initiated by either ECAD or MCAD

- Stateless and Concurrent design process

True 3D PCB design

With both ECAD and MCAD working on the same Fusion 360 environment with one dataset, 3D PCB data such as board copper, core material, and components can be analyzed, verified, and validated on the MCAD side to ensure they meet product design specifications, including:

- Specify 3D PCB data properties such as copper to run design simulation

- Check for collisions and interferences

- One source of truth ensuring design teams working on the most recent dataset

Engineers can now access comprehensive electronics and PCB design tools in one product development platform. Converge your ECAD and MCAD workflows for unified electronics design so you can engineer, design, and make anything.

To find out more about how Fusion 360 can help your team achieve the new possible, visit Autodesk.

.png?width=854&height=480&ext=.png)