The Benefits of a Multidisciplinary Design for Machine Builders

The Benefits of a Multidisciplinary Design for Machine Builders

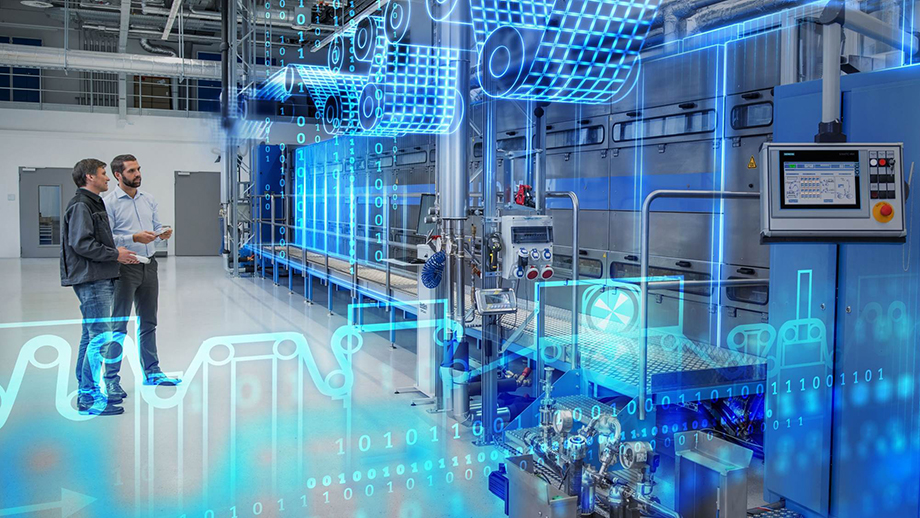

A fully integrated portfolio of software and services is needed in today’s manufacturing industry, to personalize a customer industry-specific needs for digital enterprises.

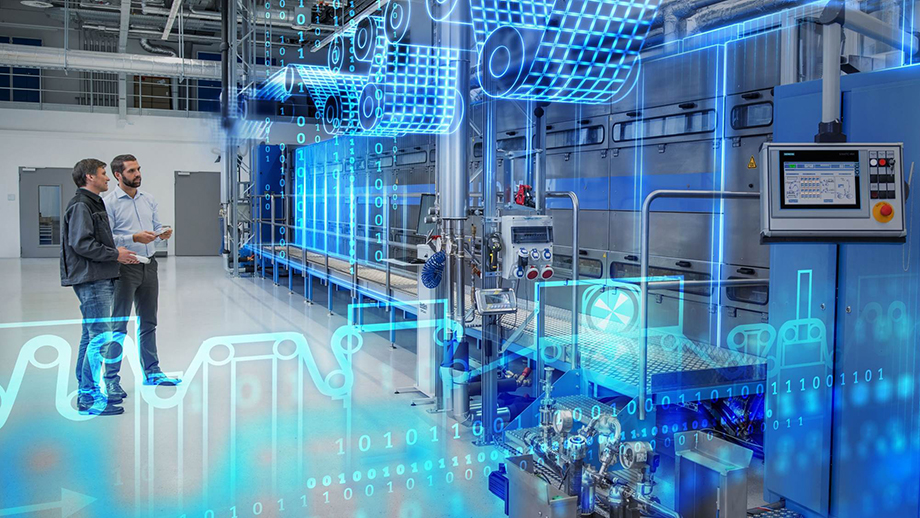

In manufacturing, building a machine is a complicated process. Historically, the focus was on the mechanical CAD, and the functioning mechanical arrangement and assembly. Today’s sophisticated machines are still mechanical marvels, but over the last two decades, electrical power is now a part of motors, rotary equipment, and camshaft gears. Moreover, all are driven by advanced computing via the software, controlled by PLCs and CNCs. Gone are the days of addressing the mechanical design in one space and the electrical design and schematics in another. The software must be part of the equation in providing optimum design.

Now more than ever, all the engineering disciplines need to work closely together to ensure the design is completed on time and cost-effectively manufactured and commissioned. That’s why machine manufacturers are leveraging a multidisciplinary design approach, spurring manufacturing to greater efficiency. Multidisciplinary design is assessing the complexities of machine building, including engineering design and manufacturing.

However, this dynamic is ever-changing with motors and equipment transitioning to gears driven by software and PLC codes, thus accelerating the desire for performance-based programs. The software must be adaptable to conditions on the floor with the machine reacting to real-time sensor readings. Simplistic processes, like a cylinder, extending and retracting, can be based on the pressure differential and flow regulation – technologies unavailable in the past to small and medium-sized businesses due to cost. This scenario increases mechanical capabilities and features with software – a game-changer for machine designers.

Read the Latest Bioengineering Blog: Advanced Design and Manufacturing Tools Empower Personalized Medicine

The multidisciplinary design blends all the capabilities and skillsets needed for advanced machine engineering into a collaborative environment. It pays dividends for the output quality of the machine design with everything working together in its place. It is a type of art form as opposed to merely bolting on electrical, sensors, and cable runs. It is more than that — it is an integrated solution. This dynamic creates harmony in the multidisciplinary design when each discipline has separate areas.

All engineering disciplines need to work in close collaboration to ensure a design is completed on time and manufactured and commissioned cost-effectively. Siemens Digital Industries Software offers solutions that demonstrate how a multidisciplinary design approach can blend these capabilities and skillsets into a collaborative environment, yielding dividends in the form of quality machine design.

Manufacturers can no longer follow the established method: “we used to design it – build it and then see if it actually worked by testing it.” Now machinery companies have aggressively compressed timelines to get their more sophisticated machinery to market. That is why there is a substantial increase around embedding simulation into the design process, and incorporating multidiscipline domain, finite element analysis, computational fluid dynamics, vibration, and harshness.

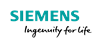

Machine builders are also relying on a comprehensive digital twin. The digital twin holistically is a representation of the physical machine, its performance, and the recipe for manufacturing it. So, it corresponds to everything that constitutes the machine: mechanical, electrical, hydraulic, fluid, pneumatics, design domains, performance, simulation, and automation code. Moreover, the digital twin encompasses manufacturing and service life, basically taking the machine from the point of origination through to the end of life, when it gets recycled.

You May Also Like: Simulation-Driven Design: Feasible or Fallacy?

Furthermore, design exploration is more profitable when simulating the entire digital machine for displaying performance in the virtual world. Therefore, items like Mechatronics Concept Designer, which is a digital industry software with specific capabilities around kinematics to define PLC code, use these capabilities to portray a virtual twin, allowing designers to find failures quickly, thus performing more work in the beginning. Realistically, it’s the same work traditionally completed by the team but now achieved in a synchronized, collaborative manner.

Manufacturing companies are attaining improved levels of optimization within the mechanical system by performing kinematics with the electrical and software teams before the physical product or prototype even exists. This setting allows for uncovering the limitations of the desired mechanism and building that knowledge into mechanical behavior—a compelling paradigm shift in machine design.

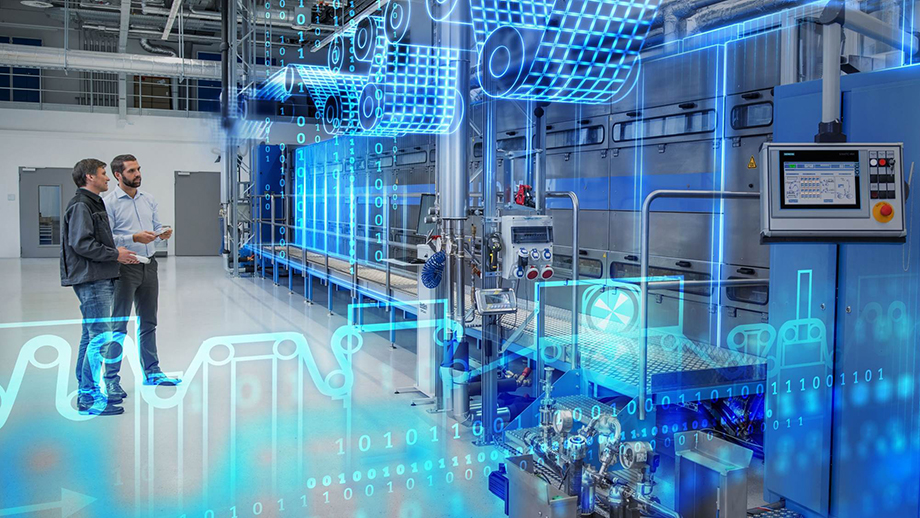

Another powerful benefit of adopting a multidisciplinary approach to machine design is virtual machine simulation and commissioning. This term refers to how a machine proves or validates the software code in the virtual world before physically operating on the factory floor.

More and more, the software is driving the machines. That is why simulating the code running on a virtual twin of the machine generates substantial dividends in time and resources. With virtual commissioning, validations of the PLC software are in a managed environment with an entire modular product development strategy. Now machine builders can perform the simulation upfront and link the software to the modules.

From a financial perspective, virtual commissioning and visualization pay significant dividends for companies. No one purchases a machine sight unseen. Also, they will not purchase it merely on a claim that it has been virtually simulated by running software code. A customer needs to substantiate that a machine works before shipping it to their plant.

However, because many software integrations and safety factors are necessary to run a machine, this becomes a stressful and monumental task to perform physically with the customer in attendance. Therefore, a virtual world is ideal for turning a machine on and performing real commissioning. There is less pressure for both the machine builder and its customers. Also, it brings together the engineering upfront in the design and the collaboration of various disciplines in testing the machine code.

A fully integrated portfolio of software, services, and application development platform, such as Siemens’ Xcelerator, personalizes and adapts to fit customer and industry-specific needs for digital enterprises. This dynamic provides a managed environment with a fully modular product development strategy, propelling companies to realize they can beat their competitors to market by having the simulation upfront and linking the software to the modules. This scenario is a significant groundbreaking achievement for companies to be competitive in this space.

To learn more about Advanced Machine Engineering and the Xcelerator portfolio, please visit: Siemens Advanced Machine Engineering

A Multidisciplinary Design Approach

Now more than ever, all the engineering disciplines need to work closely together to ensure the design is completed on time and cost-effectively manufactured and commissioned. That’s why machine manufacturers are leveraging a multidisciplinary design approach, spurring manufacturing to greater efficiency. Multidisciplinary design is assessing the complexities of machine building, including engineering design and manufacturing.

However, this dynamic is ever-changing with motors and equipment transitioning to gears driven by software and PLC codes, thus accelerating the desire for performance-based programs. The software must be adaptable to conditions on the floor with the machine reacting to real-time sensor readings. Simplistic processes, like a cylinder, extending and retracting, can be based on the pressure differential and flow regulation – technologies unavailable in the past to small and medium-sized businesses due to cost. This scenario increases mechanical capabilities and features with software – a game-changer for machine designers.

Read the Latest Bioengineering Blog: Advanced Design and Manufacturing Tools Empower Personalized Medicine

The multidisciplinary design blends all the capabilities and skillsets needed for advanced machine engineering into a collaborative environment. It pays dividends for the output quality of the machine design with everything working together in its place. It is a type of art form as opposed to merely bolting on electrical, sensors, and cable runs. It is more than that — it is an integrated solution. This dynamic creates harmony in the multidisciplinary design when each discipline has separate areas.

All engineering disciplines need to work in close collaboration to ensure a design is completed on time and manufactured and commissioned cost-effectively. Siemens Digital Industries Software offers solutions that demonstrate how a multidisciplinary design approach can blend these capabilities and skillsets into a collaborative environment, yielding dividends in the form of quality machine design.

A New Approach To Machining

Manufacturers can no longer follow the established method: “we used to design it – build it and then see if it actually worked by testing it.” Now machinery companies have aggressively compressed timelines to get their more sophisticated machinery to market. That is why there is a substantial increase around embedding simulation into the design process, and incorporating multidiscipline domain, finite element analysis, computational fluid dynamics, vibration, and harshness.

Machine builders are also relying on a comprehensive digital twin. The digital twin holistically is a representation of the physical machine, its performance, and the recipe for manufacturing it. So, it corresponds to everything that constitutes the machine: mechanical, electrical, hydraulic, fluid, pneumatics, design domains, performance, simulation, and automation code. Moreover, the digital twin encompasses manufacturing and service life, basically taking the machine from the point of origination through to the end of life, when it gets recycled.

You May Also Like: Simulation-Driven Design: Feasible or Fallacy?

Furthermore, design exploration is more profitable when simulating the entire digital machine for displaying performance in the virtual world. Therefore, items like Mechatronics Concept Designer, which is a digital industry software with specific capabilities around kinematics to define PLC code, use these capabilities to portray a virtual twin, allowing designers to find failures quickly, thus performing more work in the beginning. Realistically, it’s the same work traditionally completed by the team but now achieved in a synchronized, collaborative manner.

Manufacturing companies are attaining improved levels of optimization within the mechanical system by performing kinematics with the electrical and software teams before the physical product or prototype even exists. This setting allows for uncovering the limitations of the desired mechanism and building that knowledge into mechanical behavior—a compelling paradigm shift in machine design.

Software Code Validation

Another powerful benefit of adopting a multidisciplinary approach to machine design is virtual machine simulation and commissioning. This term refers to how a machine proves or validates the software code in the virtual world before physically operating on the factory floor.

More and more, the software is driving the machines. That is why simulating the code running on a virtual twin of the machine generates substantial dividends in time and resources. With virtual commissioning, validations of the PLC software are in a managed environment with an entire modular product development strategy. Now machine builders can perform the simulation upfront and link the software to the modules.

From a financial perspective, virtual commissioning and visualization pay significant dividends for companies. No one purchases a machine sight unseen. Also, they will not purchase it merely on a claim that it has been virtually simulated by running software code. A customer needs to substantiate that a machine works before shipping it to their plant.

However, because many software integrations and safety factors are necessary to run a machine, this becomes a stressful and monumental task to perform physically with the customer in attendance. Therefore, a virtual world is ideal for turning a machine on and performing real commissioning. There is less pressure for both the machine builder and its customers. Also, it brings together the engineering upfront in the design and the collaboration of various disciplines in testing the machine code.

Making Multidisciplinary Machine Design A Reality

A fully integrated portfolio of software, services, and application development platform, such as Siemens’ Xcelerator, personalizes and adapts to fit customer and industry-specific needs for digital enterprises. This dynamic provides a managed environment with a fully modular product development strategy, propelling companies to realize they can beat their competitors to market by having the simulation upfront and linking the software to the modules. This scenario is a significant groundbreaking achievement for companies to be competitive in this space.

To learn more about Advanced Machine Engineering and the Xcelerator portfolio, please visit: Siemens Advanced Machine Engineering