Reinventing the Robotic Wrist

Reinventing the Robotic Wrist

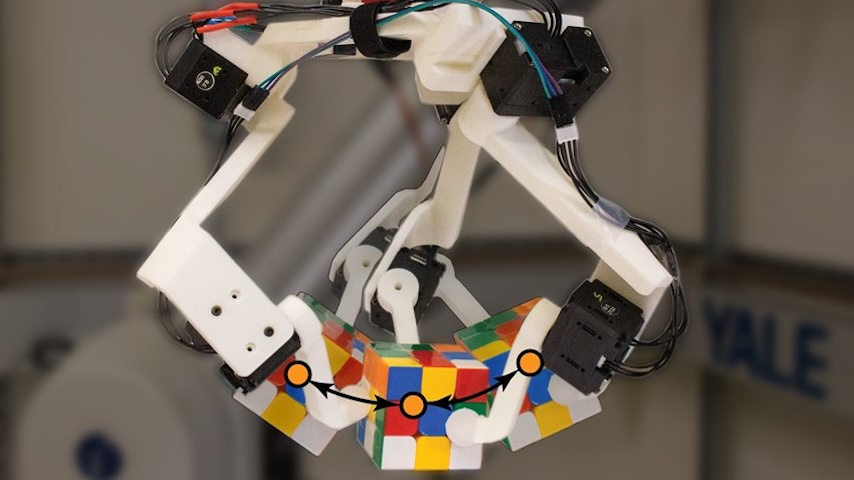

A new spherical joint may allow robotic arms to rotate and manipulate objects with more accuracy and efficiency.

From karate moves in “The Karate Kid” to video game playing in “TRON: Legacy”, movie characters are fond of explaining their exceptional skills as being “all in the wrist.” Robots, however, have lacked that kind of joint dexterity and control.

Nowadays, robotic hands can often move in three degrees of freedom: roll, pitch, and yaw. The roll consists of turning back to front, the pitch involves moving side to side, and the yaw entails moving up and down. However, combining the three to perform more complex tasks, such as screwing in a light bulb or opening a jar, is often beyond their capabilities.

Aaron Dollar, Frederick W. Beinecke Professor of Mechanical Engineering at Yale University, and colleagues have created a new and simpler robotic wrist design using a parallel mechanisms approach, paving the way for future robotic arms and other robotic systems to manage more complex tasks that require wrist control.

Relevant Reads: AI and Robotic Massage, Delivered On-Demand

“Wrist control is primarily a design challenge—but there’s a big engineering challenge associated with it, too,” Vatsal Patel said, a doctoral candidate in Dollar’s laboratory. “If you think about the human wrist, it’s incredibly competent in the things it’s able to do but it’s very tiny. It’s hard to provide that same kind of function in a robot in that small amount of space.”

According to Patel, previous wrist joint designs require a number of sensors and motors at the end of a robotic arm, including the weight of its gripper or hand. It’s challenging to add all those features and still provide the requisite three degrees of freedom for movement.

“You can add a lot of things to help a robotic arm move the way you want it to, but it can make the end of the arm super heavy,” Patel explained. “Since most wrist designers want the arm to be able to move as close as possible to the object it intends to move, all that weight can get in the way.”

Dollar’s laboratory has done extensive work in prosthetics research. Patel said it’s important to note that many prosthetic arms don’t have wrists because of the design and weight challenges. However, Dollar, Patel, and colleagues decided to look to parallel mechanisms to help create a smaller, efficient, and much more effective wrist joint that does not require the entire robotic arm to move, roll, pitch, and yaw.

“Typical robot manipulators are designed with serial chains. You stack one motor on top of another. We have serial mechanisms in human hands, too—the shoulder, the elbow, and then wrist,” he said. “But the benefit of parallel mechanisms is that you can do a lot more things in a more compact space…so we decided to find a parallel mechanism that could mimic the motions of a wrist.”

Discover the Benefits of ASME Membership

As a result, the design combines the functions of the gripper with the motions of a wrist in a single mechanism so the robot can grasp and rotate an object without the addition of additional sensors or cameras. While it’s light and small, it can get close enough to objects to perform tasks in more constrained spaces, like screwing a lightbulb into a desk lamp or inside a closet.

“This approach gives you a cool kind of control over the object so you can move it blindly,” he said. “But we still need to do more work to optimize the control. It’s still not that reliable—and it’s partially why we don’t see robot hands all over the place. So, we will continue to discover different parallel mechanisms we can use to create a robotic hand that can grasp, turn, and apply different forces on objects.”

When asked what he hopes that engineers take away from his and Dollar’s work in parallel mechanisms, Patel said he thinks greater advances in robotic joints will be from exploring a variety of architectures for potential designs.

“We have great natural sensors built into our skin. We have a great vision. We have so much dexterity. And those things don’t add weight to the hand,” he said. “So, by looking behind the design of human hands, you may be able to find new ways to control more complex movements.”

Patel continued, “We are really excited to explore alternate architectures that can make robots capable and still allow us to do the things that hands and wrists do in a very reliable way.”

Kayt Sukel is a technology writer and author in Houston.

Nowadays, robotic hands can often move in three degrees of freedom: roll, pitch, and yaw. The roll consists of turning back to front, the pitch involves moving side to side, and the yaw entails moving up and down. However, combining the three to perform more complex tasks, such as screwing in a light bulb or opening a jar, is often beyond their capabilities.

Aaron Dollar, Frederick W. Beinecke Professor of Mechanical Engineering at Yale University, and colleagues have created a new and simpler robotic wrist design using a parallel mechanisms approach, paving the way for future robotic arms and other robotic systems to manage more complex tasks that require wrist control.

Relevant Reads: AI and Robotic Massage, Delivered On-Demand

“Wrist control is primarily a design challenge—but there’s a big engineering challenge associated with it, too,” Vatsal Patel said, a doctoral candidate in Dollar’s laboratory. “If you think about the human wrist, it’s incredibly competent in the things it’s able to do but it’s very tiny. It’s hard to provide that same kind of function in a robot in that small amount of space.”

According to Patel, previous wrist joint designs require a number of sensors and motors at the end of a robotic arm, including the weight of its gripper or hand. It’s challenging to add all those features and still provide the requisite three degrees of freedom for movement.

“You can add a lot of things to help a robotic arm move the way you want it to, but it can make the end of the arm super heavy,” Patel explained. “Since most wrist designers want the arm to be able to move as close as possible to the object it intends to move, all that weight can get in the way.”

Dollar’s laboratory has done extensive work in prosthetics research. Patel said it’s important to note that many prosthetic arms don’t have wrists because of the design and weight challenges. However, Dollar, Patel, and colleagues decided to look to parallel mechanisms to help create a smaller, efficient, and much more effective wrist joint that does not require the entire robotic arm to move, roll, pitch, and yaw.

“Typical robot manipulators are designed with serial chains. You stack one motor on top of another. We have serial mechanisms in human hands, too—the shoulder, the elbow, and then wrist,” he said. “But the benefit of parallel mechanisms is that you can do a lot more things in a more compact space…so we decided to find a parallel mechanism that could mimic the motions of a wrist.”

Discover the Benefits of ASME Membership

As a result, the design combines the functions of the gripper with the motions of a wrist in a single mechanism so the robot can grasp and rotate an object without the addition of additional sensors or cameras. While it’s light and small, it can get close enough to objects to perform tasks in more constrained spaces, like screwing a lightbulb into a desk lamp or inside a closet.

“This approach gives you a cool kind of control over the object so you can move it blindly,” he said. “But we still need to do more work to optimize the control. It’s still not that reliable—and it’s partially why we don’t see robot hands all over the place. So, we will continue to discover different parallel mechanisms we can use to create a robotic hand that can grasp, turn, and apply different forces on objects.”

When asked what he hopes that engineers take away from his and Dollar’s work in parallel mechanisms, Patel said he thinks greater advances in robotic joints will be from exploring a variety of architectures for potential designs.

“We have great natural sensors built into our skin. We have a great vision. We have so much dexterity. And those things don’t add weight to the hand,” he said. “So, by looking behind the design of human hands, you may be able to find new ways to control more complex movements.”

Patel continued, “We are really excited to explore alternate architectures that can make robots capable and still allow us to do the things that hands and wrists do in a very reliable way.”

Kayt Sukel is a technology writer and author in Houston.

.png?width=854&height=480&ext=.png)