Pumping It Up at Rocky River

Pumping It Up at Rocky River

First built in 1926, Rocky River’s pumped storage facility is still Connecticut’s largest battery—and an ASME Mechanical Engineering Landmark.

The flow of water has been doing our work for a few thousand years, hulling grain, crushing ore, and powering other tasks people would rather not do themselves.

The work that hydropower could help with expanded dramatically when, in the late 19th century, turbines began to be used to turn the force of falling water into electricity. The Vulcan Street Plant, in Appleton, Wisc., churned out the country’s first hydroelectric power in 1882, using the Fox River to light a few homes and industrial buildings. Thirteen years later, Niagara Falls began producing electricity to the tune of 3.7 megawatts and, shortly after, 37 megawatts. These successes heralded the start of the hydroelectric era, and by 1920, 25 percent of the country’s electricity would come from hydroelectric plants.

But the average municipality with a river had a problem. Unlike the lucky recipients of electricity from the incessant roar of Niagara Falls, any factory built along a smaller river is subject to fickle nature. Waters rise and fall depending on the season and the weather, as do any dams built on them to generate power. What they needed was some way of storing that power when the flow was plentiful for the times when it was not.

The industries along the Housatonic River, which meanders down from Pittsfield, Mass., through western Connecticut to the Connecticut Sound, understood this need keenly. Metal working factories had begun to take advantage of the river in the early 20th century and, as it attracted more and more businesses, the need for power grew.

“In that universe, in the 1920s, there was really only hydro—your factories didn’t really run unless you had hydroelectric associated with it,” said Brian Wood, FirstLight Power’s senior land manager. “If you didn’t have hydroelectric, you couldn’t run the Industrial Revolution.”

To meet the increasing energy demands of these growing industries, Connecticut personality, lawyer, politician, and businessman, J. Henry Roraback wielded his many powers and abilities. He put his lawyerly, political, and business skills to bear to orchestrate the merging of several energy companies (with the help of the United Gas and Improvement Company, or UGI), to build the Stevenson dam on the Housatonic, and to create—and become president of—the Connecticut Light and Power Company. His many efforts provided more electricity, to be sure, but did not fix the problem of providing consistent ready power to the industries along the river.

Looking for solutions, Roraback took a trip to Switzerland to visit a pumped power solution there, which had (likely) been in use since 1882. He came back determined to build something similar. He proposed damming a short tributary of the Housatonic, the Rocky River, and thereby creating a giant reservoir from which to draw extra flow and power as needed. Dams, of course, had been done before, but Roraback wanted to refill this new reservoir with water pumped up from below, as needed. Plans were drawn up in 1926 and in that same year work was started.

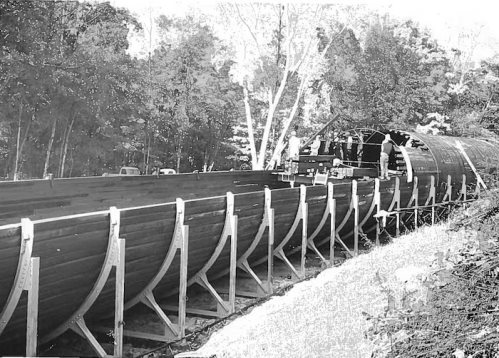

That work was no small affair. Roraback created Rocky River Realty (an entity that still exists today) to buy the land, sometimes from willing sellers, sometimes with state authorized power of condemnation. Then it took 1,000 men, living in a camp they called UGIville to clear the land and build the infrastructure. This was a task they accomplished before the invention of the excavator. Instead, they used wood fired steam shovels and cable drags.

“It was just an incredible feat of engineering, and had some pretty significant environmental consequences, when you think about it,” said Richard Laudenat, retired plant manager of FirstLight’s Connecticut facilities, including the Rocky River Pumped Hydro Energy Storage Station (and ASME president from 2019-2020). “The deforestation that took place, moving graves, and moving existing towns—it was pretty significant.”

The lake submerged and subsumed four smaller bodies of water—the Squantz, the Barse, the Crick and the poorly named Neversink—and flooded farms, churches, schools and highways. The water was held in place by five small dams and one primary dam, which was 952 feet long, a hundred feet tall, and sat a mile from where the Rocky River ran into the Housatonic. The result was the 6,000-acre, 11-mile-long, Candlewood Lake, now a place for boats, swimming, beauteous views, and a battery to boot.

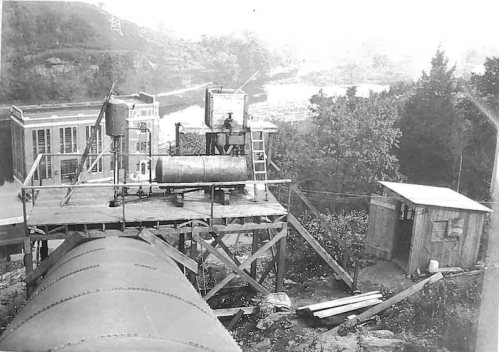

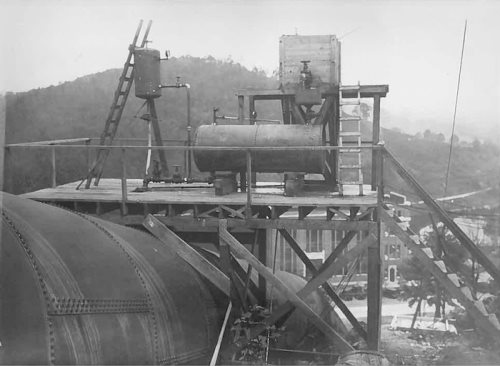

But this giant reservoir of potential energy was only the top half of the engineering marvel. 230 feet below the primary dam, in New Milford, a Westinghouse generator and two of the largest pumps ever built, 8,100 horsepower each—and made by GE—did the work of sending water back up to the lake, at a rate of 112,500 gallons a minute. That meant the lake sat there ready to provide 29 megawatts as needed.

“Rocky River represents the first example of load growth that was in excess of the ability of the free-flowing river, the dammed rivers, to provide power,” Laudenat said. “In the 1920s, when it was conceived, that was a pretty huge amount of electricity.” And no one in the world had ever pumped water higher than the 230 feet covered by those pumps.

They were put to use just as soon as they were built. The brass mills took direct power from the Housatonic during the day. At night, the same power would be used to refill the lake. “In the morning, when everybody showed up on the trolley cars—that were powered by hydro—they would turn on Rocky River to fire up all the industrial equipment. It would only run for a couple of hours to get everything spinning,” Wood said.

Unlike more recently built pumped storage systems, the pumps in New Milford, as initially designed, did not work as generators when they weren’t pumping. But soon after they were running the engineers realized that there was a missed opportunity—the pumps run in reverse could easy have increased the capacity of the plant. Luckily, the engineers who designed the original plant included a ring gate, a metal sleeve to separate the generator from the pumps when they were pumping.

“That was part of the original design, because they realized that these two, massive, 8,000-horsepower pumps next to this big generator would try to push that generator out of the floor,” said Wood.

That ring gate would allow the pumps to be retrofitted in the 1950s so that they could produce electricity when run in reverse. “We flip a switch, and it switches the polarity, and the pump becomes a generator, or the generator becomes a pump,” Wood said. “Though they run a lot less efficiently than they would if they’d been designed to be reversible from the start, it’s essentially free extra energy that hadn’t been planned for.”

The most amazing thing about the Rocky River Pumped Storage facility is that (if you’ve noticed the tenses in this article wavering from past to present) it’s still in use, and with mostly the same parts. The original wooden 1,000-foot penstock that connects the power station to Candlewood Lake was replaced in the 1950s and is now a fiberglass pipe. Aside from that, it’s almost all legacy stuff. The pumps, aside from the circuitry that made them reversible, are all original. The generator, though it’s been overhauled several times, is all original. The surge tower that sits on a hill behind the plant is all original, as is the piping that connects it to the turbine.

“If you fast forward from the day the plant was built to now, there’s not much that has changed,” Laudenat said.

The longevity of the parts—and the whole—mean the value derived from its construction is essentially inestimable. And Rocky River requires just a fraction of the employees of a coal powered plant.

“It’s like a giant watch sitting on the ground—all these huge gears and pieces at this massive scale—you’re literally working inside of a 100-year-old watch. And very rarely we take a part out of it and say, ‘Oh, we have a better way.’ We don’t have a better way,” Wood said. “No engineer is walking in there and going, ‘Hey, I got a greater idea. I can do this easier.’ They figured it out right the first time.”

No longer does the Candlewood supply power to mills or metal working factories. Instead, it works to supplement electricity as needed during peak hours of demand. The 29-megawatt water battery is capable of powering local communities for 24 hours straight, providing 720 megawatts a day of generation. In theory it could go for longer, but the Federal Energy Regulatory Commission has set that limit on the draw down. “There’s nothing uglier than a lake that’s way below its normal level,” Laudenant said.

The century old pumps and lake are just the kind of storage that so many involved with energy are looking for now. “Everybody wants to build a battery in order to have this new, cutting-edge technology,” Wood said. “We have a battery that’s been operating for 100 years. It’s not cutting edge—it’s a 30-megawatt battery sitting there—Connecticut’s largest battery.”

At a time when storing energy is as much an issue as creating it, Rocky River is as relevant as it’s ever been. As more and more renewable sources are added to the grid, it’s essential that we find ways to meet peak demand when the sun’s not shining and the wind’s not blowing. And pumped storage like Rocky River does just that.

“It’s kind of funny,” said Claire Belanger, FirstLight’s director of corporate communications. “All this old stuff becomes new again—they probably couldn’t have foreseen this need, but it really is a perfect tool to capture that generation and deploy it later on, when it’s needed. I think it’s pretty cool that these facilities have been around for 100 years, and they’re just as relevant to our current needs as they were when they were originally constructed.”

Michael Abrams is a technology writer in Westfield, N.J.

The work that hydropower could help with expanded dramatically when, in the late 19th century, turbines began to be used to turn the force of falling water into electricity. The Vulcan Street Plant, in Appleton, Wisc., churned out the country’s first hydroelectric power in 1882, using the Fox River to light a few homes and industrial buildings. Thirteen years later, Niagara Falls began producing electricity to the tune of 3.7 megawatts and, shortly after, 37 megawatts. These successes heralded the start of the hydroelectric era, and by 1920, 25 percent of the country’s electricity would come from hydroelectric plants.

But the average municipality with a river had a problem. Unlike the lucky recipients of electricity from the incessant roar of Niagara Falls, any factory built along a smaller river is subject to fickle nature. Waters rise and fall depending on the season and the weather, as do any dams built on them to generate power. What they needed was some way of storing that power when the flow was plentiful for the times when it was not.

The industries along the Housatonic River, which meanders down from Pittsfield, Mass., through western Connecticut to the Connecticut Sound, understood this need keenly. Metal working factories had begun to take advantage of the river in the early 20th century and, as it attracted more and more businesses, the need for power grew.

“In that universe, in the 1920s, there was really only hydro—your factories didn’t really run unless you had hydroelectric associated with it,” said Brian Wood, FirstLight Power’s senior land manager. “If you didn’t have hydroelectric, you couldn’t run the Industrial Revolution.”

An engineering feat

To meet the increasing energy demands of these growing industries, Connecticut personality, lawyer, politician, and businessman, J. Henry Roraback wielded his many powers and abilities. He put his lawyerly, political, and business skills to bear to orchestrate the merging of several energy companies (with the help of the United Gas and Improvement Company, or UGI), to build the Stevenson dam on the Housatonic, and to create—and become president of—the Connecticut Light and Power Company. His many efforts provided more electricity, to be sure, but did not fix the problem of providing consistent ready power to the industries along the river.

Looking for solutions, Roraback took a trip to Switzerland to visit a pumped power solution there, which had (likely) been in use since 1882. He came back determined to build something similar. He proposed damming a short tributary of the Housatonic, the Rocky River, and thereby creating a giant reservoir from which to draw extra flow and power as needed. Dams, of course, had been done before, but Roraback wanted to refill this new reservoir with water pumped up from below, as needed. Plans were drawn up in 1926 and in that same year work was started.

That work was no small affair. Roraback created Rocky River Realty (an entity that still exists today) to buy the land, sometimes from willing sellers, sometimes with state authorized power of condemnation. Then it took 1,000 men, living in a camp they called UGIville to clear the land and build the infrastructure. This was a task they accomplished before the invention of the excavator. Instead, they used wood fired steam shovels and cable drags.

“It was just an incredible feat of engineering, and had some pretty significant environmental consequences, when you think about it,” said Richard Laudenat, retired plant manager of FirstLight’s Connecticut facilities, including the Rocky River Pumped Hydro Energy Storage Station (and ASME president from 2019-2020). “The deforestation that took place, moving graves, and moving existing towns—it was pretty significant.”

The lake submerged and subsumed four smaller bodies of water—the Squantz, the Barse, the Crick and the poorly named Neversink—and flooded farms, churches, schools and highways. The water was held in place by five small dams and one primary dam, which was 952 feet long, a hundred feet tall, and sat a mile from where the Rocky River ran into the Housatonic. The result was the 6,000-acre, 11-mile-long, Candlewood Lake, now a place for boats, swimming, beauteous views, and a battery to boot.

But this giant reservoir of potential energy was only the top half of the engineering marvel. 230 feet below the primary dam, in New Milford, a Westinghouse generator and two of the largest pumps ever built, 8,100 horsepower each—and made by GE—did the work of sending water back up to the lake, at a rate of 112,500 gallons a minute. That meant the lake sat there ready to provide 29 megawatts as needed.

“Rocky River represents the first example of load growth that was in excess of the ability of the free-flowing river, the dammed rivers, to provide power,” Laudenat said. “In the 1920s, when it was conceived, that was a pretty huge amount of electricity.” And no one in the world had ever pumped water higher than the 230 feet covered by those pumps.

They were put to use just as soon as they were built. The brass mills took direct power from the Housatonic during the day. At night, the same power would be used to refill the lake. “In the morning, when everybody showed up on the trolley cars—that were powered by hydro—they would turn on Rocky River to fire up all the industrial equipment. It would only run for a couple of hours to get everything spinning,” Wood said.

Unlike more recently built pumped storage systems, the pumps in New Milford, as initially designed, did not work as generators when they weren’t pumping. But soon after they were running the engineers realized that there was a missed opportunity—the pumps run in reverse could easy have increased the capacity of the plant. Luckily, the engineers who designed the original plant included a ring gate, a metal sleeve to separate the generator from the pumps when they were pumping.

“That was part of the original design, because they realized that these two, massive, 8,000-horsepower pumps next to this big generator would try to push that generator out of the floor,” said Wood.

That ring gate would allow the pumps to be retrofitted in the 1950s so that they could produce electricity when run in reverse. “We flip a switch, and it switches the polarity, and the pump becomes a generator, or the generator becomes a pump,” Wood said. “Though they run a lot less efficiently than they would if they’d been designed to be reversible from the start, it’s essentially free extra energy that hadn’t been planned for.”

Built to last

The most amazing thing about the Rocky River Pumped Storage facility is that (if you’ve noticed the tenses in this article wavering from past to present) it’s still in use, and with mostly the same parts. The original wooden 1,000-foot penstock that connects the power station to Candlewood Lake was replaced in the 1950s and is now a fiberglass pipe. Aside from that, it’s almost all legacy stuff. The pumps, aside from the circuitry that made them reversible, are all original. The generator, though it’s been overhauled several times, is all original. The surge tower that sits on a hill behind the plant is all original, as is the piping that connects it to the turbine.

“If you fast forward from the day the plant was built to now, there’s not much that has changed,” Laudenat said.

The longevity of the parts—and the whole—mean the value derived from its construction is essentially inestimable. And Rocky River requires just a fraction of the employees of a coal powered plant.

“It’s like a giant watch sitting on the ground—all these huge gears and pieces at this massive scale—you’re literally working inside of a 100-year-old watch. And very rarely we take a part out of it and say, ‘Oh, we have a better way.’ We don’t have a better way,” Wood said. “No engineer is walking in there and going, ‘Hey, I got a greater idea. I can do this easier.’ They figured it out right the first time.”

No longer does the Candlewood supply power to mills or metal working factories. Instead, it works to supplement electricity as needed during peak hours of demand. The 29-megawatt water battery is capable of powering local communities for 24 hours straight, providing 720 megawatts a day of generation. In theory it could go for longer, but the Federal Energy Regulatory Commission has set that limit on the draw down. “There’s nothing uglier than a lake that’s way below its normal level,” Laudenant said.

The century old pumps and lake are just the kind of storage that so many involved with energy are looking for now. “Everybody wants to build a battery in order to have this new, cutting-edge technology,” Wood said. “We have a battery that’s been operating for 100 years. It’s not cutting edge—it’s a 30-megawatt battery sitting there—Connecticut’s largest battery.”

At a time when storing energy is as much an issue as creating it, Rocky River is as relevant as it’s ever been. As more and more renewable sources are added to the grid, it’s essential that we find ways to meet peak demand when the sun’s not shining and the wind’s not blowing. And pumped storage like Rocky River does just that.

“It’s kind of funny,” said Claire Belanger, FirstLight’s director of corporate communications. “All this old stuff becomes new again—they probably couldn’t have foreseen this need, but it really is a perfect tool to capture that generation and deploy it later on, when it’s needed. I think it’s pretty cool that these facilities have been around for 100 years, and they’re just as relevant to our current needs as they were when they were originally constructed.”

Michael Abrams is a technology writer in Westfield, N.J.

.png?width=854&height=480&ext=.png)