Pumping Extremely Hot Metal, Part 1

Pumping Extremely Hot Metal, Part 1

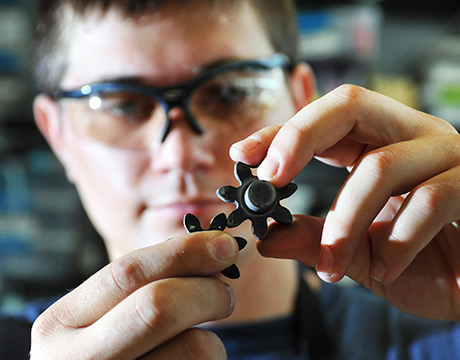

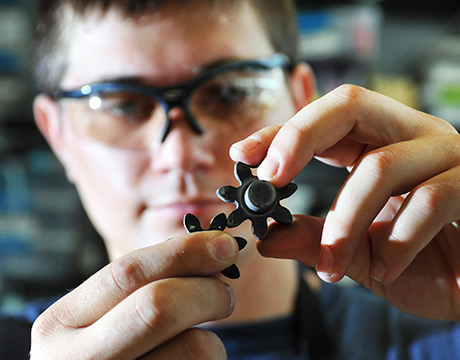

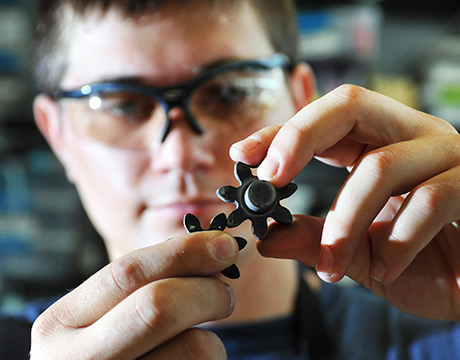

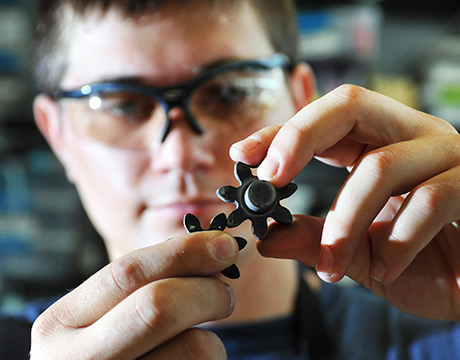

For two long days and nights, Professor Asegun Henry’s team of researchers at Georgia Tech’s Woodruff School of Mechanical Engineering anxiously watched their new ceramic pump move molten tin heated to record-high temperatures. At any moment, they expected something to go wrong. The extreme heat could shatter a shaft, break a bearing, melt a seal, as it did during countless tests conducted throughout the pump’s four-year development cycle. The students were forced to monitor the machine in case it started leaking dangerously hot metal. They didn’t want to burn down the lab.

Henry and his students hoped this test would be different. Over the years, the team developed a number of innovations and improvements to perfect a pump they and others expect to spur a new generation of highly efficient, low-cost systems for storing, transporting, and converting surplus thermal energy produced by renewables like solar and wind. It could serve as a new, cheaper type of battery that could generate electricity when needed, big challenge in the advancement of renewable energy. The nuclear and chemical processing industries, among others, could also use the system for advanced applications.

It’s a big undertaking because you have to change the whole infrastructure of the system.Prof. Asegun Henry, Georgia Tech

To handle those needs, the pump had to withstand temperatures that could exceed 1,600 °K (1,326 °C), making it the first of its kind. As testing moved into its third day, the new pump held. Based on past failures, though, the team expected the worst.

The Challenge

Almost every form of energy conversion creates heat, making it one of the most prevalent forms of energy. When used for mechanical work, thermal energy is most efficient when it can be moved, stored, and converted at its highest possible temperature. But most of today’s pumps and compressors can’t handle that extreme heat and must be stored in a cooler part of the system, limiting the system’s overall efficiency. The components – usually made from superalloys and ceramics – break, corrode, weaken, or wear when exposed to high-temperature liquids for an extended period.

The need for a stable heat storage and transfer system is especially important for advanced and emerging nuclear energy applications. The system, for example, could serve as a less expensive, more efficient, and faster way to cool down a reactor in case of an emergency. Finding that solution, Henry says, has been a “grand challenge” in the nuclear energy industry and one of the main reasons the Advanced Research Projects Agency – Energy (ARPA-E) is funding his work.

“The scary thing with nuclear is the runaway effect, where the reactor heats up faster than you can cool it,” Henry says. “This type of pump can move heat faster, and the liquid will stay warmer before it boils. That buys you a whole lot of safety.”

Please see Part 2 of “Pumping Extremely Hot Metal” to discover the challenges Henry and his team faced in designing the pump, how they overcame those challenges, and if the new design passed the test.

Read More:

Nanotechnology Fuels Safe Lithium Ion Batteries

Green Air Conditioning

Flying to Space on Butterfly Wings

.png?width=854&height=480&ext=.png)