Plant Burrs Inspire Strong Sutures for Soft Tendons

Plant Burrs Inspire Strong Sutures for Soft Tendons

A plant's burrs and their hooks offer a solution to stiffness issues in sutures used to connect tendons to bone.

A burr by any other name can be just as clingy, but the species Harpagonella palmeri has inspired a new method of suturing rotator cuff injuries that could change how stitches are done in tendon-to-bone surgeries.

It all started with the usual chats between two Washington University at St. Louis faculty members. Mechanical engineering professor Guy Genin, who’s also co-director of the National Science Foundation-funded Center for Engineering MechanoBiology (CEMB), and the late professor emerita of biology Barbara Pickard, were talking about the intersection of mechanical engineering and biology. Genin and another collaborator, Columbia University professor Stavros Thomopoulos, had been trying for a decade to solve the 20 percent to 94 percent failure rate of rotator cuff procedures, tied to the re-tearing of tendon-to-bone connections and the need to “regenerate that interface,” Genin said.

“The problem is that sutures are really stiff compared to tendons,” explained Ethan D. Hoppe, Genin’s former graduate student researcher. “Tissues aren’t as strong as they used to be [and are] deteriorating, so stiffnesses is even worse. The suture cuts through tendon like a wire through cheese.”

Eventually, discussions turned to Velcro, “the burr-inspired connectors with hooks and loops that are too random for a surgeon to tolerate,” Genin said. “The basic principle is that this type of disorder often improves toughness of an interface” and makes attachments stronger.

Try This Quiz: Robots Inspired by Nature

In relation, Pickard told them of the H. palmeri—also known as Palmer's grappling-hook hitchhiker plants—whose burrs attached to her socks on a long-ago hike. The team obtained some of the fruits from Matt Guilliams, the plant systematist and curator of the Clifton Smith Herbarium at the Santa Barbara Botanic Garden.

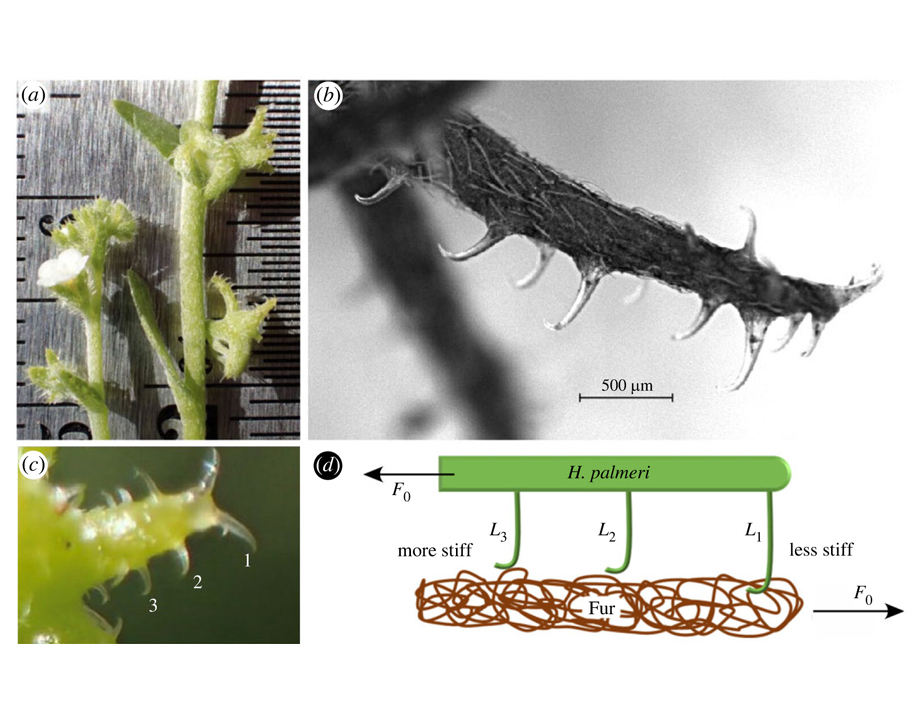

The burrs’ unique qualities enable their stiff hooks to be particularly tenacious in hanging onto soft material like animal fur or people’s socks, further inspiring a better way to attach stiff sutures to softer tissue such as tendons.

Hoppe studied the burrs under a microscope and “began seeing a pattern between the length of the hooks, and the spacing,” he said, unique compared to those of other hitchhiker plants’ fruits. Hooks furthest away from the center are longer and the hooks closest to the center are shorter.

He was lead author on "A discrete shear lag model of the mechanics of hitchhiker plants, and its prospective application to tendon-to-bone repair," published in Proceedings of the Royal Society A. The paper notes that the team had to keep certain practicalities of surgery in mind. “We sought ways to even the distribution of forces over an idealized repair with three rows of sutures,” it states. “More than three rows of sutures are not practical in rotator cuff repair due to space limitations on the humeral head.”

The team applied relatively simple, “Physics I” level mathematics for balancing forces, as well as discrete shear-lag and continuous Volkerson shear lag models.

Become a Member: How to Join ASME

To determine the stiffness of hooks at different locations and of varying lengths, they used a simple model of cantilevers. “We found the radius and the length of the hooks, and by using those parameters we could assign stiffness, then plugged that into our equations,” Hoppe said. “We found the forces balanced much better. In seeds, having a longer first hook is going to affect stiffness. If all the hooks were the same, all the force would be caught at the front. If first hook is softer, then some of forces are distributed to other hooks.”

“The mathematical model of how forces are distributed over the hooks came together quickly, and we were stunned by the result that such a simple technique exists to balance forces over sutures,” Genin said. “It was so obvious in retrospect.”

Also obvious to researchers was that the solution would somehow be found in the natural world. “Nature has solutions for all kinds of mechanical engineering problems, especially problems in surgery where the goal is to work with natural tissues,” Genin noted.

Hoppe recalls taking a biomimetic approach and studying the teeth of pythons, which are long and slender and thus have a softer stiffness. Genin adds that they also looked at “remarkable adhesives” produced by mussels that work underwater, and thinks those could also become a viable solution, though they “require significant manipulation before they can be used in the setting of a surgery.”

You Might Also Enjoy: Tattooed on the Heart

Thomopoulos, who is also director of the Carroll Laboratories for Orthopedic Surgery at Columbia, is now conducting preclinical testing of the new suture methods. Genin says that existing materials will continue to be used.

“Sutures come in a range of standard sizes and materials that yield stiffnesses well within the range of what is needed to balance forces over a repair site,” he explained. “In our initial tests, we have not had to create new sutures, and we do not anticipate needing to.”

Once these experiments conclude, the researchers will present this idea at the Orthopedic Research Society meeting, Genin said. The team already presented their research at an annual conference by ASME’s Bioengineering Division, to positive response. “Mechanical engineers have no trouble seeing the merit and beauty of a system in which mechanical forces are balanced so well,” he added.

Eydie Cubarrubia is an editor and writer based in New York City.

Pulse of the Profession: Career-Ready Soft Skills

.png?width=854&height=480&ext=.png)