Metamaterials in Concrete Produce Electricity

Metamaterials in Concrete Produce Electricity

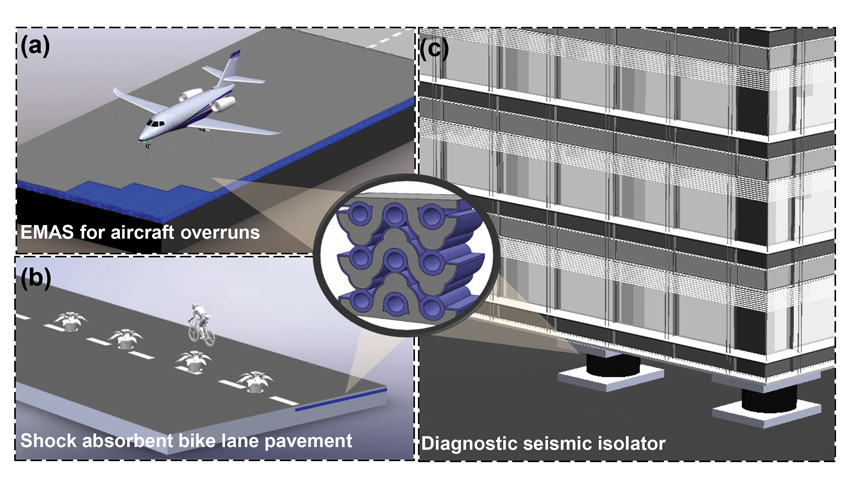

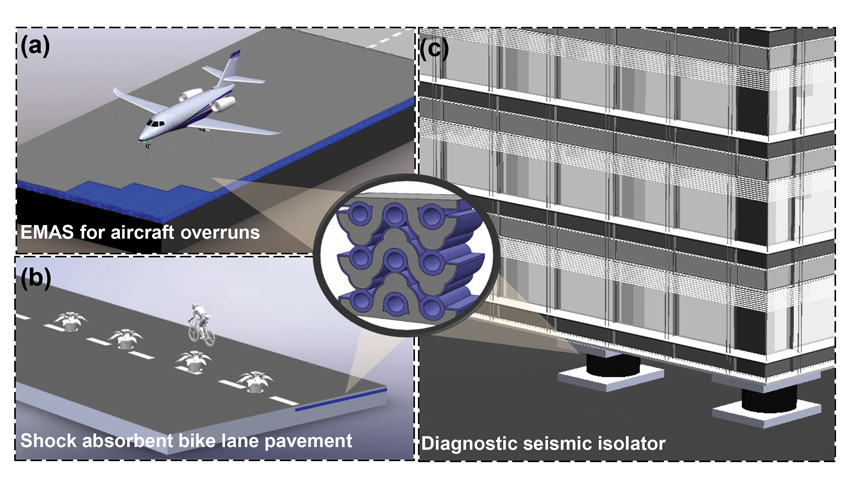

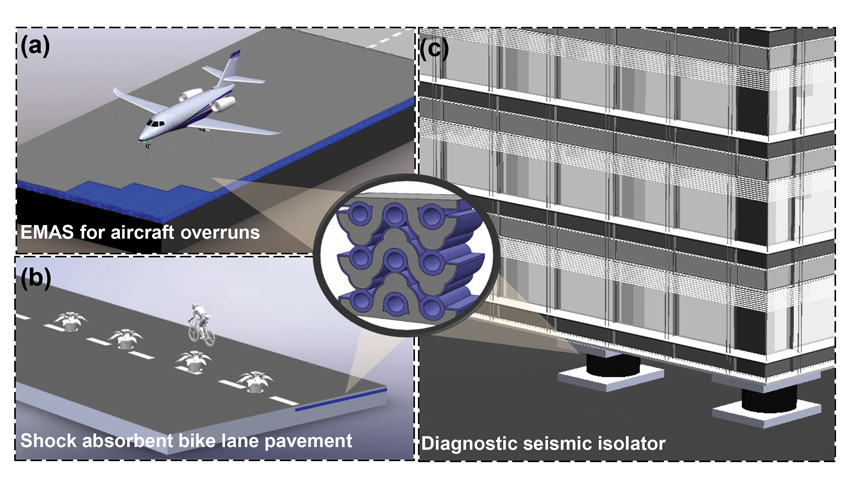

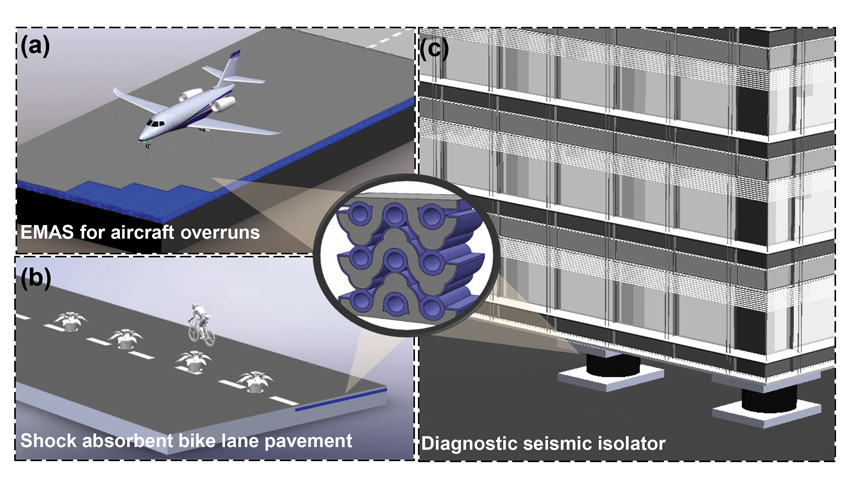

Compressible concrete can produce power, slow airplanes, or work in seismic base isolators. Image: Amir Alavi

Concrete is the most widely used building material in the world, with its use dating back to the Roman Empire. It can be designed for a variety of uses, with numerous mixes and additives used for specific projects. Researchers now are trying to move the ubiquitous material into the digital age using metamaterials that promote compressibility and even the production of electricity.

“I’m talking about intelligence in materials,” said Amir Alavi, an assistant professor of civil and environmental engineering at the University of Pittsburgh. “I’m talking about advanced functionalities in a material that can actuate or harvest energy.”

Alavi and his team have been working with metamaterials for more than five years, developing a metamaterial system that acts as its own sensor and records and relays information about pressures and stress on a structure. His latest development uses metamaterials in the creation of concrete, making it possible for it to be specifically designed for a particular job.

Become a Member: How to Join ASME

The work, “Multifunctional Nanogenerator-Integrated Metamaterial Concrete Systems for Smart Civil Infrastructure,” was published on Advanced Materials. Using metamaterials, the mix can be fine-tuned for characteristics such as flexibility or brittleness and allow builders to use less material without losing strength.

Alavi said the work shows the first composite metamaterial concrete with super compressibility and energy harvesting capability, and can lead to uses in applications such as shock-absorbing engineered materials at airports to help slow planes on a runway, or even seismic base isolation systems.

It also is capable of generating small amounts of electricity, enough to power roadway or nearby sensors, he said. Electrical signals are self-generated under “mechanical excitations” and can be used to monitor damage inside a structure made of the concrete. As technology develops, the smart concrete could possibly power chips embedded within it to help self-driving cars navigate on roads.

“The point is that I can mechanically tune properties to any desired property,” he said. “The one you are seeing in the paper is 15 percent compressibility. If you compress it, it recovers. Or it can be 20 percent or 50 percent by geometrical design.”

The key is a flexible auxetic polymer lattice embedded in a cement matrix. For the tests, the team 3D-printed the lattice structures and poured a cement mix into them to create the metamaterial structure, Alavii said. They then added graphite because they wanted the material to be conductive.

“It uses a mechanism called contact electrification,” he said. “You’ve seen it before when you rub a balloon to your hair. What happens is, when you apply mechanical excitation, you’re forcing contact electrification between the conductive {concrete] and the polymer lattices, and it generates a signal.”

More for You: Shock-Absorbing Material Holds Promise for Impact Protection

In tests, the material has shown it can compress up to 15 percent under cyclic loading and produce 330 microWatts of electricity.

“We use about 2 percent graphite in the concrete to make it conductive,” Alavi said. “You can make concrete as nonconductive, and add a polymer as a conductor, but conductive polymers are very expensive. That’s why we decided to do an inverse design. Concrete and graphite are not really expensive, and it’s very affordable for a large scale.”

Alavi’s previous work on sensors led him to this development. Tiny sensors made of electric materials work well in small items such as implants, he said, but are not practical for scaling up to something like a bridge deck, he noted.

“I’d need to deploy thousands of them,” he said. “So I stopped thinking about them for this phase, and started working on multi-functional materials where we would not need a piece of electrical material. We just design the structure, and there in the middle of the material is the functionality.”

He claims the work is a new paradigm in the development of construction materials. The Pennsylvania Department of Transportation funded the work,, and is interested in applying the concept to state roads and save on concrete and other materials.

Lattices make the concrete lighter, and produce the same performance with less weight, he said.

Great volumes of concrete will continue to be used for infrastructure and buildings, and the digitalization of society implies the need for new concrete materials that are economical and environmentally sustainable but contain functionalities needed for new technologies. Alavi and his team believe using metamaterials produces a new paradigm into the development of new construction materials.

John Kosowatz is senior editor.

“I’m talking about intelligence in materials,” said Amir Alavi, an assistant professor of civil and environmental engineering at the University of Pittsburgh. “I’m talking about advanced functionalities in a material that can actuate or harvest energy.”

Alavi and his team have been working with metamaterials for more than five years, developing a metamaterial system that acts as its own sensor and records and relays information about pressures and stress on a structure. His latest development uses metamaterials in the creation of concrete, making it possible for it to be specifically designed for a particular job.

Become a Member: How to Join ASME

The work, “Multifunctional Nanogenerator-Integrated Metamaterial Concrete Systems for Smart Civil Infrastructure,” was published on Advanced Materials. Using metamaterials, the mix can be fine-tuned for characteristics such as flexibility or brittleness and allow builders to use less material without losing strength.

Alavi said the work shows the first composite metamaterial concrete with super compressibility and energy harvesting capability, and can lead to uses in applications such as shock-absorbing engineered materials at airports to help slow planes on a runway, or even seismic base isolation systems.

It also is capable of generating small amounts of electricity, enough to power roadway or nearby sensors, he said. Electrical signals are self-generated under “mechanical excitations” and can be used to monitor damage inside a structure made of the concrete. As technology develops, the smart concrete could possibly power chips embedded within it to help self-driving cars navigate on roads.

“The point is that I can mechanically tune properties to any desired property,” he said. “The one you are seeing in the paper is 15 percent compressibility. If you compress it, it recovers. Or it can be 20 percent or 50 percent by geometrical design.”

The key is a flexible auxetic polymer lattice embedded in a cement matrix. For the tests, the team 3D-printed the lattice structures and poured a cement mix into them to create the metamaterial structure, Alavii said. They then added graphite because they wanted the material to be conductive.

“It uses a mechanism called contact electrification,” he said. “You’ve seen it before when you rub a balloon to your hair. What happens is, when you apply mechanical excitation, you’re forcing contact electrification between the conductive {concrete] and the polymer lattices, and it generates a signal.”

More for You: Shock-Absorbing Material Holds Promise for Impact Protection

In tests, the material has shown it can compress up to 15 percent under cyclic loading and produce 330 microWatts of electricity.

“We use about 2 percent graphite in the concrete to make it conductive,” Alavi said. “You can make concrete as nonconductive, and add a polymer as a conductor, but conductive polymers are very expensive. That’s why we decided to do an inverse design. Concrete and graphite are not really expensive, and it’s very affordable for a large scale.”

Alavi’s previous work on sensors led him to this development. Tiny sensors made of electric materials work well in small items such as implants, he said, but are not practical for scaling up to something like a bridge deck, he noted.

“I’d need to deploy thousands of them,” he said. “So I stopped thinking about them for this phase, and started working on multi-functional materials where we would not need a piece of electrical material. We just design the structure, and there in the middle of the material is the functionality.”

He claims the work is a new paradigm in the development of construction materials. The Pennsylvania Department of Transportation funded the work,, and is interested in applying the concept to state roads and save on concrete and other materials.

Lattices make the concrete lighter, and produce the same performance with less weight, he said.

Great volumes of concrete will continue to be used for infrastructure and buildings, and the digitalization of society implies the need for new concrete materials that are economical and environmentally sustainable but contain functionalities needed for new technologies. Alavi and his team believe using metamaterials produces a new paradigm into the development of new construction materials.

John Kosowatz is senior editor.