Metal Foam Stops Bullets

Metal Foam Stops Bullets

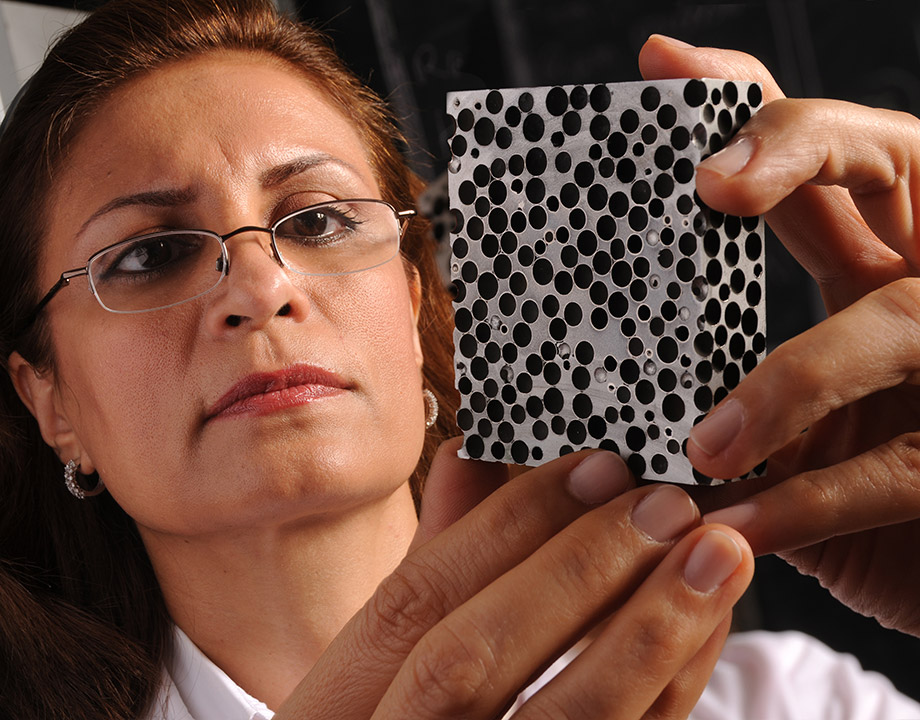

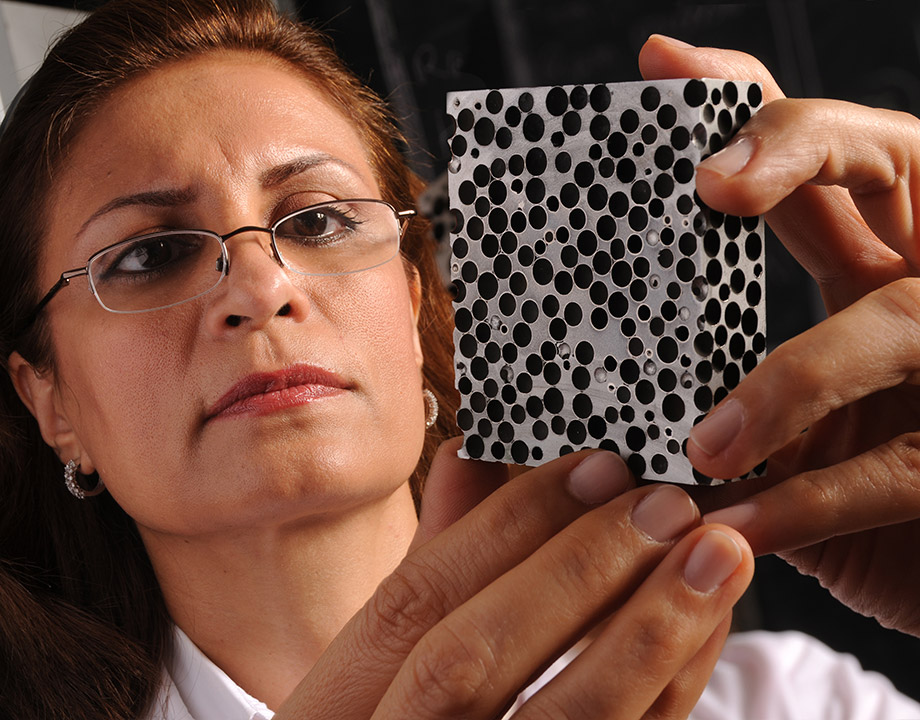

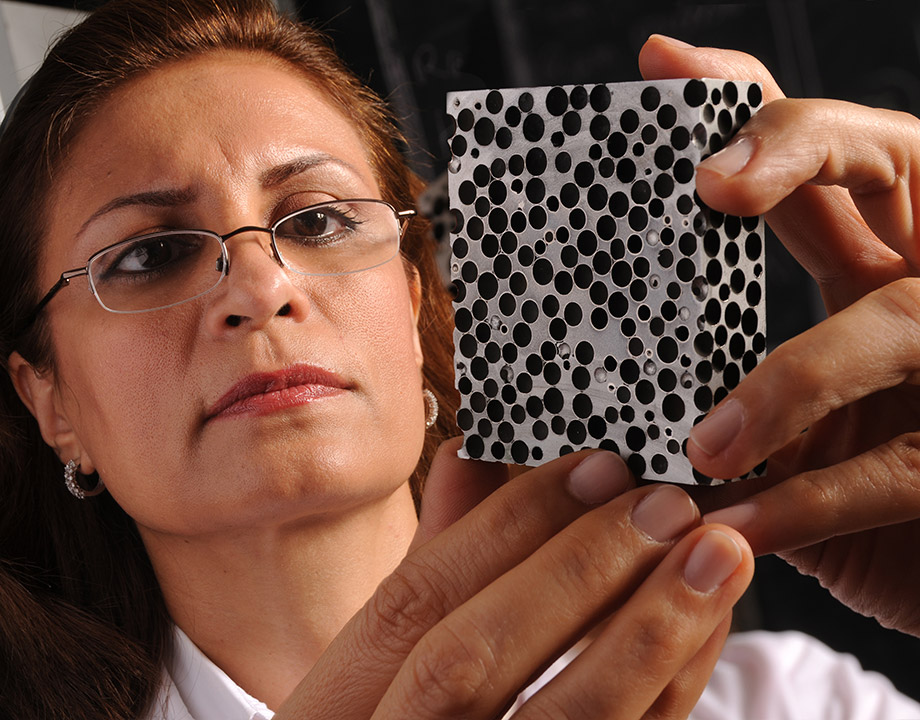

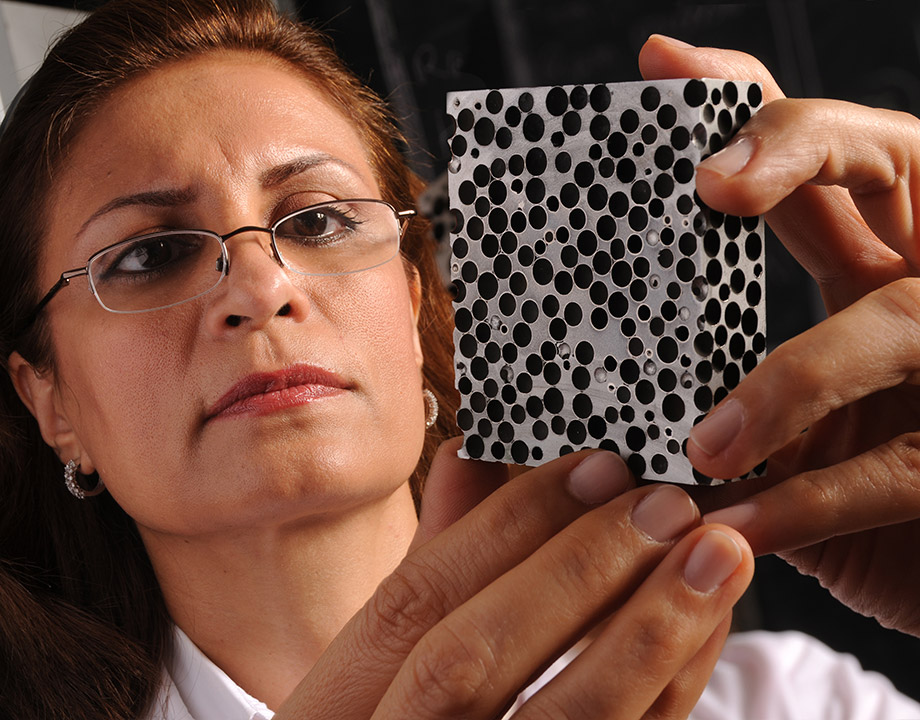

Afsaneh Rabiei gazes at her holey, bullet-nullifying, metal foam.

Foam, as we think of it, is flimsy. A foam rubber cushion will conform to the shape of our backsides, and if you announce a plan to fire a gun into a mound of shaving cream, you’re not likely to find any volunteers to stand on the other side.

If you make that foam out of metal, it turns out, it can stop a projectile.

Researchers from North Carolina State University have created just such a foam, and it can freeze the trajectory of a .50 caliber bullet better than the current armor used by the military—thick slabs of steel—at half the weight.

Metal foam has been around for a while, but up to now a millimeters-thick sheet couldn’t survive the force of two fingers, let alone an armor-piercing projectile. Those metal foams were created with a baking soda-like agent that would puff them up to create porosity. The interior bubbles formed at various sizes, like the holes in sourdough bread.

“That was metal foam before my metal foam,” said Afsaneh Rabiei, a professor of mechanical and aerospace engineering at North Carolina State University, who has spearheaded the work on metal foam armor. “I came up with the idea to use hollow spheres. Instead of random foaming, I arranged the porosity.”

Rabiei stacked hollow steel spheres and then filled the spaces in between with more steel to create a matrix. (Both the spheres and the filler could be made of any metal.) The result is a lightweight but rigid material. “It has the strength, and resistance to heat, of metal, but the cushionability of Styrofoam,” she said.

To simulate a metal-foam armor, Rabiei sandwiched a sample between a faceplate of ceramic and a backing of aluminum. The result was an armored plate about an inch thick possessing half the density of the steel slabs that currently protect military vehicles. In spite of its lightness, the composite foam armor stopped military-grade .50 caliber rounds.

Recommended for You: Penn Engineering Creates Super Strong Porous Metal

What makes the foam better than solid steel? Rabiei says the foam can absorb and dissipate energy rather than resist it.

“It can be squeezed and while under such loading it absorbs the energy, like carrying glass in a bubble wrap,” Rabiei said. “If you did not have that cushion ability in those polymers, no matter how many layers of polymer you use, still you could not carry the glass safely.”

In the test firings, Rabiei’s team found that 75 percent of the energy of the bullet was dissipated by the foam, with the rest taken up by the ceramic faceplate and by the deformation of the bullet itself.

“A lot of the bullet’s energy is absorbed through the deformation of those spheres in our composite metal foam,” she said.

There are many tweakable properties to make the foam stronger: The sphere size can be changed and different metals can be used for the spheres and the matrix. For an armor, the thickness of the foam, faceplate, and backplate need to be optimized, though right now, the first two layers are protecting the third.

“Oftentimes soldiers are not injured by a penetrating bullet but by back plate indentation impact against their organs,” Rabiei said. “And you see that our back plate is not damaged.”

Commercialization means refining the production methods. The foam can be made through casting and powder metallurgy, both of which come with advantages and disadvantages in terms of bonding the spheres to the matrix. “The production of the material itself is challenging, because you want to make a material without squeezing or squishing or damaging the spheres while you’re manufacturing,” Rabiei said.

Rabiei’s foam can also block neutrons and high-energy radiation, and does a better job at fighting off heat than the steel used as armor today. So the stuff may soon be used to ship volatile materials, protect vehicles and people in space, as well as shield military personnel and civilians in a wide variety of situations.

“I’m sure that someday it will be like bubble wrap or Styrofoam—in every household,” Rabiei said. “But before that we have a lot of work to do.”

Michael Abrams is a technology writer based in Westfield, NJ.

If you make that foam out of metal, it turns out, it can stop a projectile.

Researchers from North Carolina State University have created just such a foam, and it can freeze the trajectory of a .50 caliber bullet better than the current armor used by the military—thick slabs of steel—at half the weight.

Metal foam has been around for a while, but up to now a millimeters-thick sheet couldn’t survive the force of two fingers, let alone an armor-piercing projectile. Those metal foams were created with a baking soda-like agent that would puff them up to create porosity. The interior bubbles formed at various sizes, like the holes in sourdough bread.

“That was metal foam before my metal foam,” said Afsaneh Rabiei, a professor of mechanical and aerospace engineering at North Carolina State University, who has spearheaded the work on metal foam armor. “I came up with the idea to use hollow spheres. Instead of random foaming, I arranged the porosity.”

Rabiei stacked hollow steel spheres and then filled the spaces in between with more steel to create a matrix. (Both the spheres and the filler could be made of any metal.) The result is a lightweight but rigid material. “It has the strength, and resistance to heat, of metal, but the cushionability of Styrofoam,” she said.

To simulate a metal-foam armor, Rabiei sandwiched a sample between a faceplate of ceramic and a backing of aluminum. The result was an armored plate about an inch thick possessing half the density of the steel slabs that currently protect military vehicles. In spite of its lightness, the composite foam armor stopped military-grade .50 caliber rounds.

Recommended for You: Penn Engineering Creates Super Strong Porous Metal

What makes the foam better than solid steel? Rabiei says the foam can absorb and dissipate energy rather than resist it.

“It can be squeezed and while under such loading it absorbs the energy, like carrying glass in a bubble wrap,” Rabiei said. “If you did not have that cushion ability in those polymers, no matter how many layers of polymer you use, still you could not carry the glass safely.”

In the test firings, Rabiei’s team found that 75 percent of the energy of the bullet was dissipated by the foam, with the rest taken up by the ceramic faceplate and by the deformation of the bullet itself.

“A lot of the bullet’s energy is absorbed through the deformation of those spheres in our composite metal foam,” she said.

There are many tweakable properties to make the foam stronger: The sphere size can be changed and different metals can be used for the spheres and the matrix. For an armor, the thickness of the foam, faceplate, and backplate need to be optimized, though right now, the first two layers are protecting the third.

“Oftentimes soldiers are not injured by a penetrating bullet but by back plate indentation impact against their organs,” Rabiei said. “And you see that our back plate is not damaged.”

Commercialization means refining the production methods. The foam can be made through casting and powder metallurgy, both of which come with advantages and disadvantages in terms of bonding the spheres to the matrix. “The production of the material itself is challenging, because you want to make a material without squeezing or squishing or damaging the spheres while you’re manufacturing,” Rabiei said.

Rabiei’s foam can also block neutrons and high-energy radiation, and does a better job at fighting off heat than the steel used as armor today. So the stuff may soon be used to ship volatile materials, protect vehicles and people in space, as well as shield military personnel and civilians in a wide variety of situations.

“I’m sure that someday it will be like bubble wrap or Styrofoam—in every household,” Rabiei said. “But before that we have a lot of work to do.”

Michael Abrams is a technology writer based in Westfield, NJ.