Managing the Leidenfrost Effect in Manufacturing

Managing the Leidenfrost Effect in Manufacturing

.jpg?width=854&height=480&ext=.jpg)

.jpg?width=854&height=480&ext=.jpg)

Researchers at Purdue University have learned how to mitigate the impact the Leidenfrost Effect has on machine components, especially the lubrication of bearings and other high-speed surfaces.

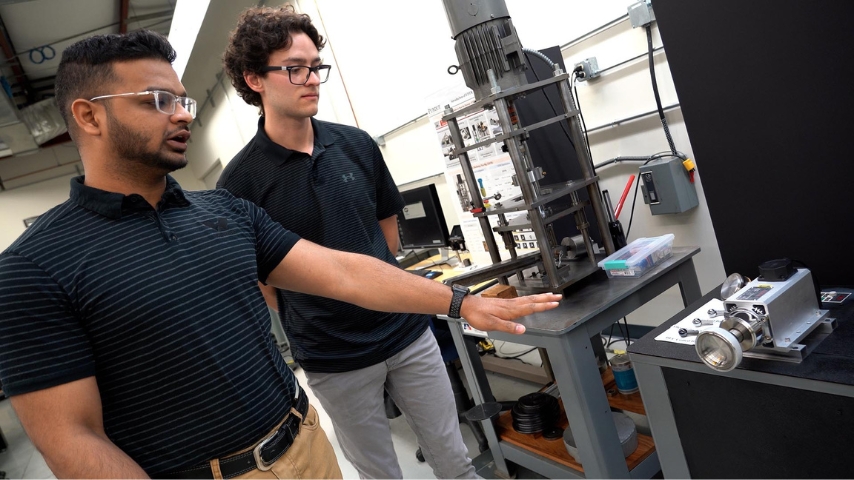

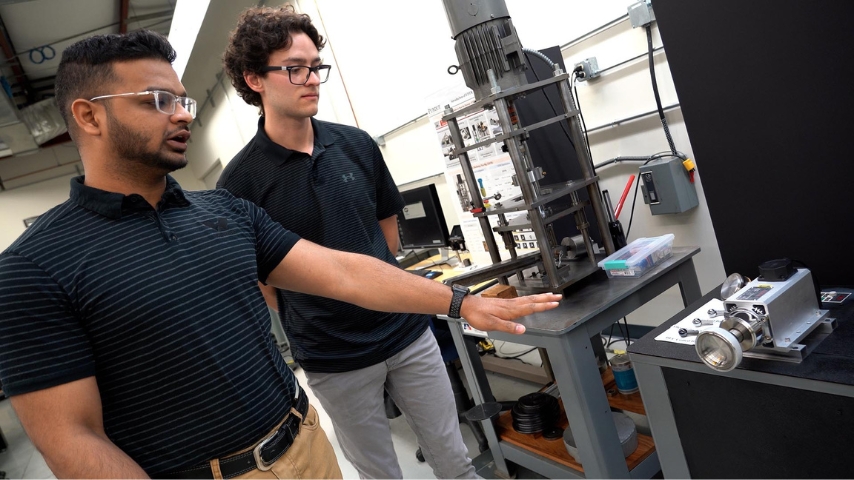

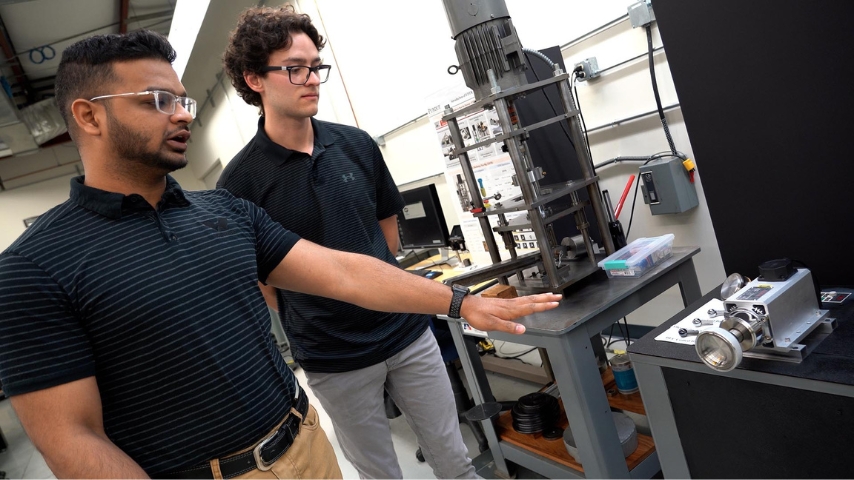

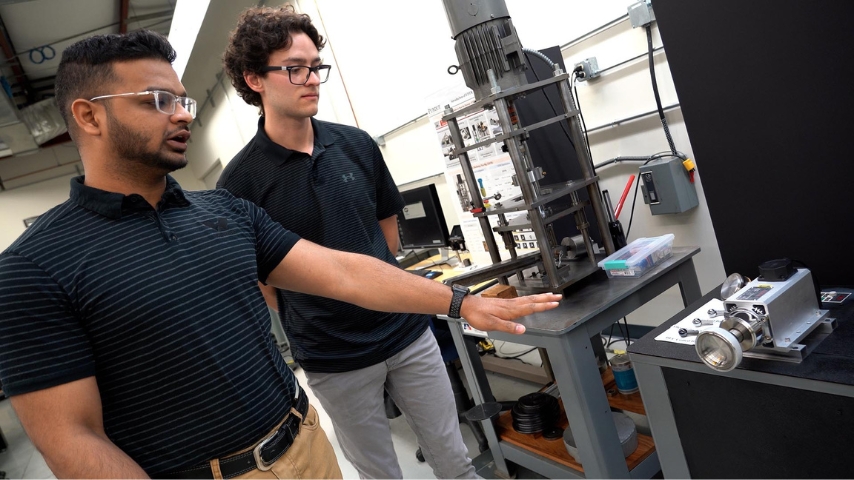

The goal of researchers at the Mechanical Engineering Tribology Lab at Purdue University is to improve the performance of machine components. To this end they have focused on rolling element bearings, which are critical to applications such as electric vehicles and high-speed machine spindles.

Machine components that make contact with each other require some sort of lubricant film to operate smoothly. During a recent investigation, the researchers observed an unexpected phenomenon: Lubricant delivered to a high-speed surface failed to adhere as anticipated. Instead, it appeared to levitate just above the surface of the component.

They then realized they had just observed the aerodynamic Leidenfrost Effect (ALE), where the aerodynamic force of high-speed rotation caused the oil droplet to levitate above the metal surface, instead of spreading across the surface. When a certain speed is reached, the droplet is supported by a cushion of air and floats over the surface, without making contact with the part below.

This observation prompted the research team—professor of mechanical engineering Farshid Sadeghi and graduate students Ujjawal Arya and Joseph Leo Misenar—to conduct a series of follow-up experiments with high-speed visualizations to learn more about how the air gap separates the lubricant stream from the rotating surface at high speeds.

Their research is detailed in two papers: “Lubricant levitation in high-speed bearings: An experimental approach,” and “Modeling of Aerodynamic Leidenfrost Effect of Oil Droplets.”

Although ALE has been observed before, Sadeghi believes this is the first time it has been tested in a potential real-world application, such as rolling element bearings. A bearing rotating at high speeds with no lubrication is a potential disaster. If the lubricant does not spread out into a film, the negative impacts start to pile up, including heavy wear, heat generation, friction, bearing failure, and shorter lifespan.

The first step was testing numerous criteria to study this levitating effect—factors such as speed of bearing rotation, coatings on the metal surface, viscosity of the lubricant, and speed and angle of how the drop was deployed. The team discovered that higher the speed, the more an air cushion forms, and the greater chance that the aerodynamic Leidenfrost effect causes the lubricant to float and not adhere to the surface.

They then built a numerical model of these floating droplets, inspired by the high-speed footage they filmed during their experiments. Variable they tested included droplet weights, surface tensions, and air speeds on the air film thickness and pressure profiles to see how they impacted the levitation of a lubricant drop near a surface at a high speed.

A major challenge was identifying the gap in the existing literature, particularly for bearings, where experimental insights into this phenomenon were limited or nonexistent. “On the numerical modeling side, it was difficult to find accurate approaches that could capture the relevant physics and highlight the key parameters influencing the behavior,” Arya said. “Experimentally, we also had to simplify complex bearing setups to a more fundamental configuration while ensuring the results remained meaningful for tribological applications.”

The team was intrigued by the fact that the threshold speed for observing the aerodynamic Leidenfrost Effect varied across different bearing components such as the ball, inner race, and outer race, which illustrates the strong influence of geometry on droplet behavior. One of the most intriguing finings was the experimentally observed droplet deformation pattern, which closely resembled the characteristic profile seen in elastohydrodynamic lubrication [EHL] contact. This “motivated us to develop a dedicated modeling approach for this phenomenon based on the EHL theory,” he explained.

This research is the first to systematically investigate impacts of ALE in the context of high-speed bearing lubrication. The team explored several mechanical engineering aspects, including a strong influence of lubricant properties—particularly extensional viscosity. “The experimental setup, though simple, was thoughtfully designed to yield clear insights with bearing components,” Arya said.

Mechanical engineers who work with machine components should be greatly interested in the role that ALE plays, especially at high operating speeds, when lubricant films separating these contact interfaces become depleted, leading to increased asperity contact and wear. “Our findings provide insight into this failure mechanism by identifying the conditions that exacerbated the phenomenon of lubricant levitation,” Arya said. “This insight can help guide the design of more effective lubrication delivery systems, ultimately reducing friction-induced heat generation and extending the life of components operating under extreme conditions."

This research has established foundational science for future engineers to follow, especially in electric vehicle industry. When choosing a lubricant, mechanical engineers must pay serious attention to selecting the right viscosity and an appropriate delivery method to minimize potential damage caused by ALE.

The team is actively extending the experimental setup to closely mimic actual bearing configurations, “which allows us to measure friction under high-speed conditions and directly relate it to the onset of ALE,” Misenar said. “This will help us better understand how this phenomenon contributes to lubricant film depletion and increased asperity contact.

The team is actively extending the experimental setup to closely mimic actual bearing configurations, “which allows us to measure friction under high-speed conditions and directly relate it to the onset of ALE,” Misenar said. “This will help us better understand how this phenomenon contributes to lubricant film depletion and increased asperity contact.

In the short-term, the researchers also plan to integrate these experimental and numerical insights into predictive models that can guide lubricant selection, optimize lubricant delivery systems, and most importantly, improve the accuracy of bearing life calculations under extreme operating conditions.

These findings have potential applications in areas where preventing liquid adhesion could be advantageous. One innovative example is automotive windshield systems. By leveraging a high-speed air curtain, it may be possible to complement or even replace traditional wipers by preventing water from sticking to the glass surface, leading to improved visibility and reduced mechanical wear.

“The same principle could be applied to design non-stick, self-cleaning surfaces in areas such as robotics, microfluidics, or medical devices where fluid control at high speeds is challenging,” Arya said.

Mark Crawford is a technology writer in Corrales, N.M.

Machine components that make contact with each other require some sort of lubricant film to operate smoothly. During a recent investigation, the researchers observed an unexpected phenomenon: Lubricant delivered to a high-speed surface failed to adhere as anticipated. Instead, it appeared to levitate just above the surface of the component.

They then realized they had just observed the aerodynamic Leidenfrost Effect (ALE), where the aerodynamic force of high-speed rotation caused the oil droplet to levitate above the metal surface, instead of spreading across the surface. When a certain speed is reached, the droplet is supported by a cushion of air and floats over the surface, without making contact with the part below.

This observation prompted the research team—professor of mechanical engineering Farshid Sadeghi and graduate students Ujjawal Arya and Joseph Leo Misenar—to conduct a series of follow-up experiments with high-speed visualizations to learn more about how the air gap separates the lubricant stream from the rotating surface at high speeds.

Their research is detailed in two papers: “Lubricant levitation in high-speed bearings: An experimental approach,” and “Modeling of Aerodynamic Leidenfrost Effect of Oil Droplets.”

A levitating effect

Although ALE has been observed before, Sadeghi believes this is the first time it has been tested in a potential real-world application, such as rolling element bearings. A bearing rotating at high speeds with no lubrication is a potential disaster. If the lubricant does not spread out into a film, the negative impacts start to pile up, including heavy wear, heat generation, friction, bearing failure, and shorter lifespan. The first step was testing numerous criteria to study this levitating effect—factors such as speed of bearing rotation, coatings on the metal surface, viscosity of the lubricant, and speed and angle of how the drop was deployed. The team discovered that higher the speed, the more an air cushion forms, and the greater chance that the aerodynamic Leidenfrost effect causes the lubricant to float and not adhere to the surface.

They then built a numerical model of these floating droplets, inspired by the high-speed footage they filmed during their experiments. Variable they tested included droplet weights, surface tensions, and air speeds on the air film thickness and pressure profiles to see how they impacted the levitation of a lubricant drop near a surface at a high speed.

Research challenges

A major challenge was identifying the gap in the existing literature, particularly for bearings, where experimental insights into this phenomenon were limited or nonexistent. “On the numerical modeling side, it was difficult to find accurate approaches that could capture the relevant physics and highlight the key parameters influencing the behavior,” Arya said. “Experimentally, we also had to simplify complex bearing setups to a more fundamental configuration while ensuring the results remained meaningful for tribological applications.”The team was intrigued by the fact that the threshold speed for observing the aerodynamic Leidenfrost Effect varied across different bearing components such as the ball, inner race, and outer race, which illustrates the strong influence of geometry on droplet behavior. One of the most intriguing finings was the experimentally observed droplet deformation pattern, which closely resembled the characteristic profile seen in elastohydrodynamic lubrication [EHL] contact. This “motivated us to develop a dedicated modeling approach for this phenomenon based on the EHL theory,” he explained.

This research is the first to systematically investigate impacts of ALE in the context of high-speed bearing lubrication. The team explored several mechanical engineering aspects, including a strong influence of lubricant properties—particularly extensional viscosity. “The experimental setup, though simple, was thoughtfully designed to yield clear insights with bearing components,” Arya said.

Mechanical engineers who work with machine components should be greatly interested in the role that ALE plays, especially at high operating speeds, when lubricant films separating these contact interfaces become depleted, leading to increased asperity contact and wear. “Our findings provide insight into this failure mechanism by identifying the conditions that exacerbated the phenomenon of lubricant levitation,” Arya said. “This insight can help guide the design of more effective lubrication delivery systems, ultimately reducing friction-induced heat generation and extending the life of components operating under extreme conditions."

Future steps

This research has established foundational science for future engineers to follow, especially in electric vehicle industry. When choosing a lubricant, mechanical engineers must pay serious attention to selecting the right viscosity and an appropriate delivery method to minimize potential damage caused by ALE.

In the short-term, the researchers also plan to integrate these experimental and numerical insights into predictive models that can guide lubricant selection, optimize lubricant delivery systems, and most importantly, improve the accuracy of bearing life calculations under extreme operating conditions.

These findings have potential applications in areas where preventing liquid adhesion could be advantageous. One innovative example is automotive windshield systems. By leveraging a high-speed air curtain, it may be possible to complement or even replace traditional wipers by preventing water from sticking to the glass surface, leading to improved visibility and reduced mechanical wear.

“The same principle could be applied to design non-stick, self-cleaning surfaces in areas such as robotics, microfluidics, or medical devices where fluid control at high speeds is challenging,” Arya said.

Mark Crawford is a technology writer in Corrales, N.M.

.jpg?width=854&height=480&ext=.jpg)

.jpg?width=854&height=480&ext=.jpg)