Hardened Diving Suit Wards Off the Bends

Hardened Diving Suit Wards Off the Bends

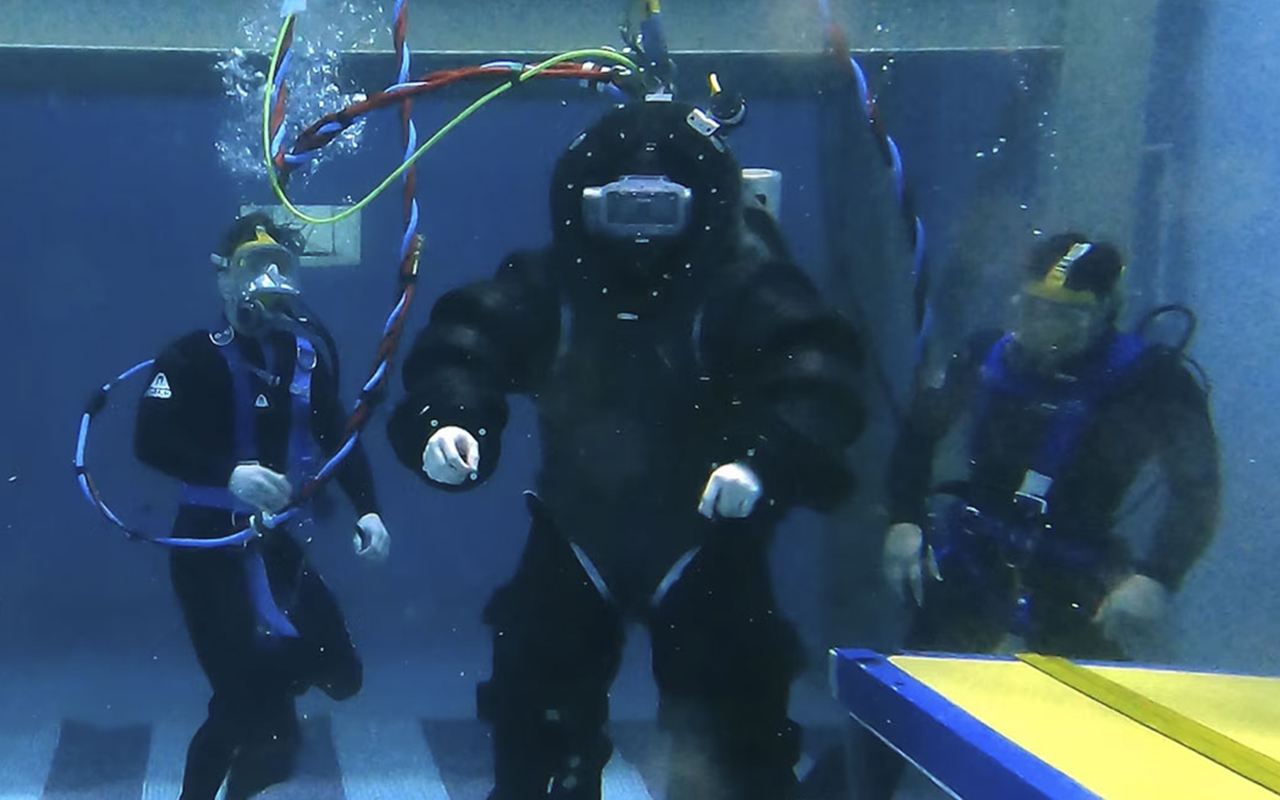

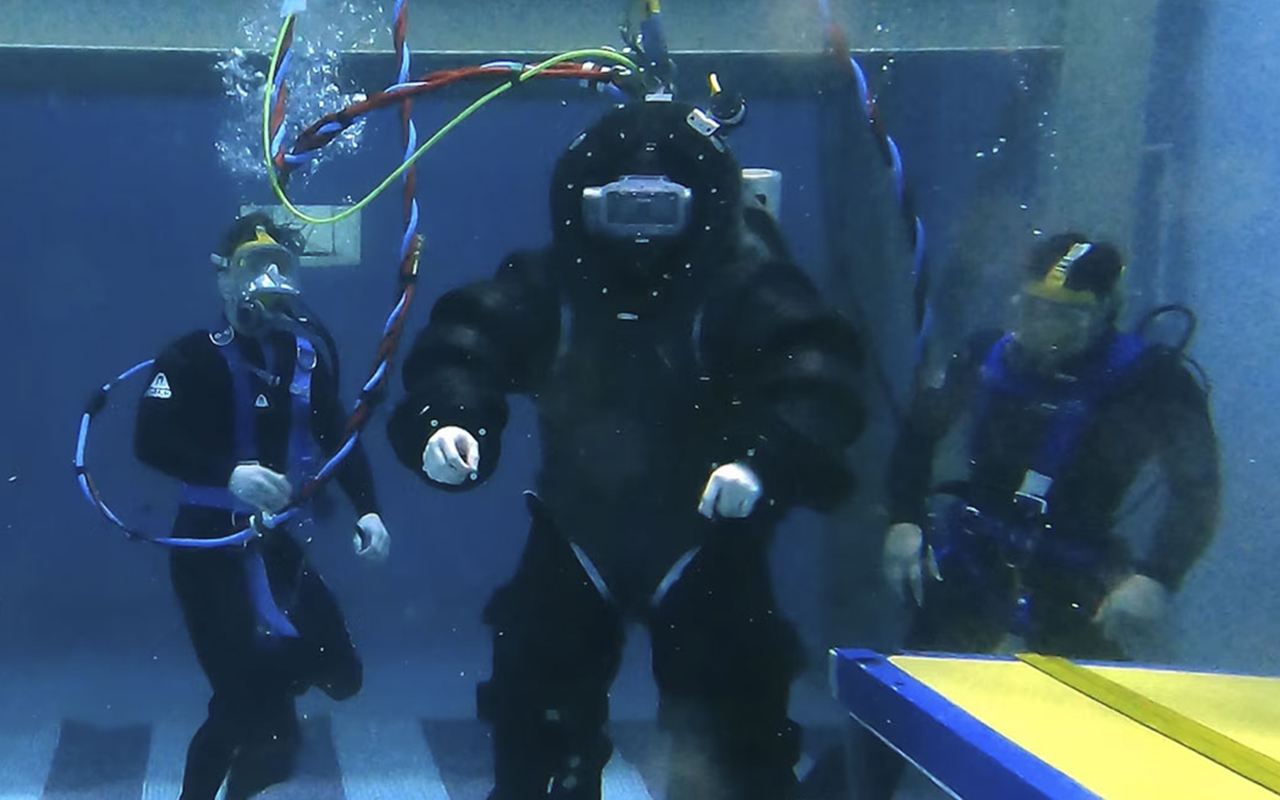

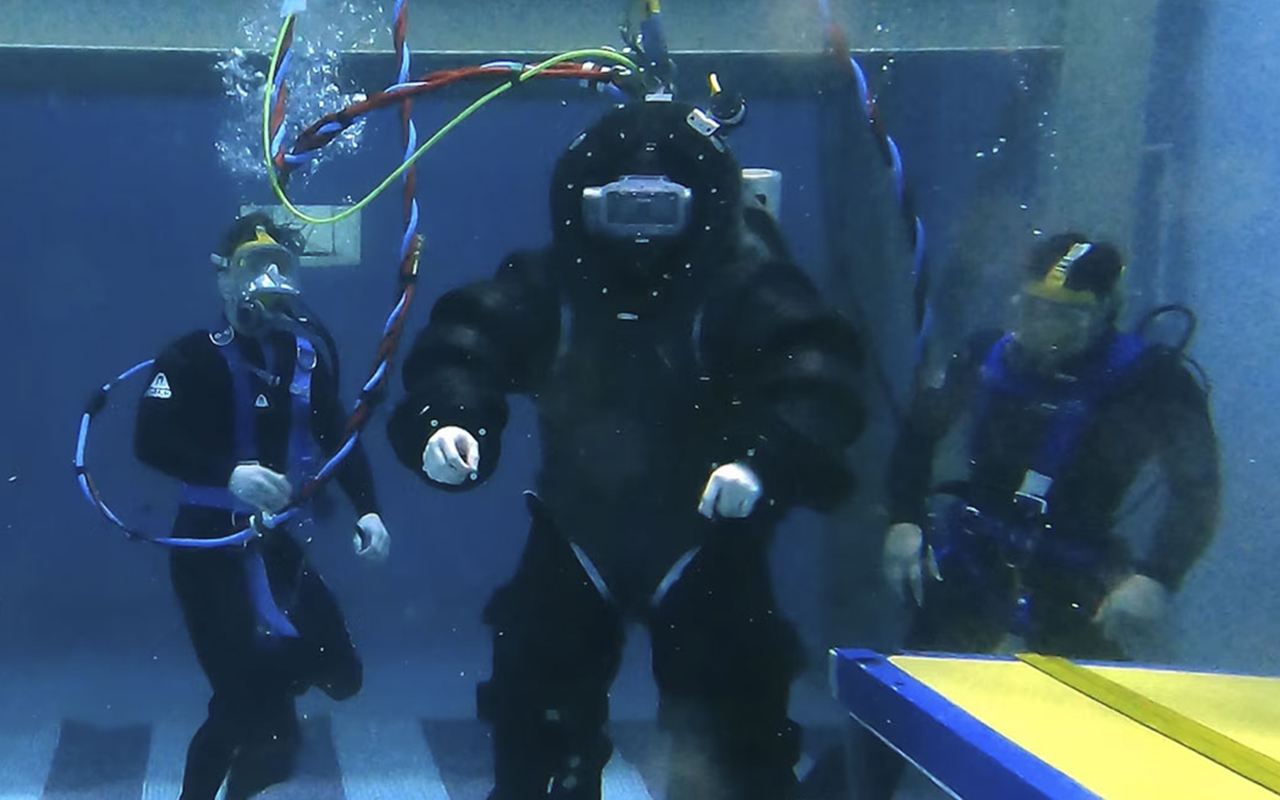

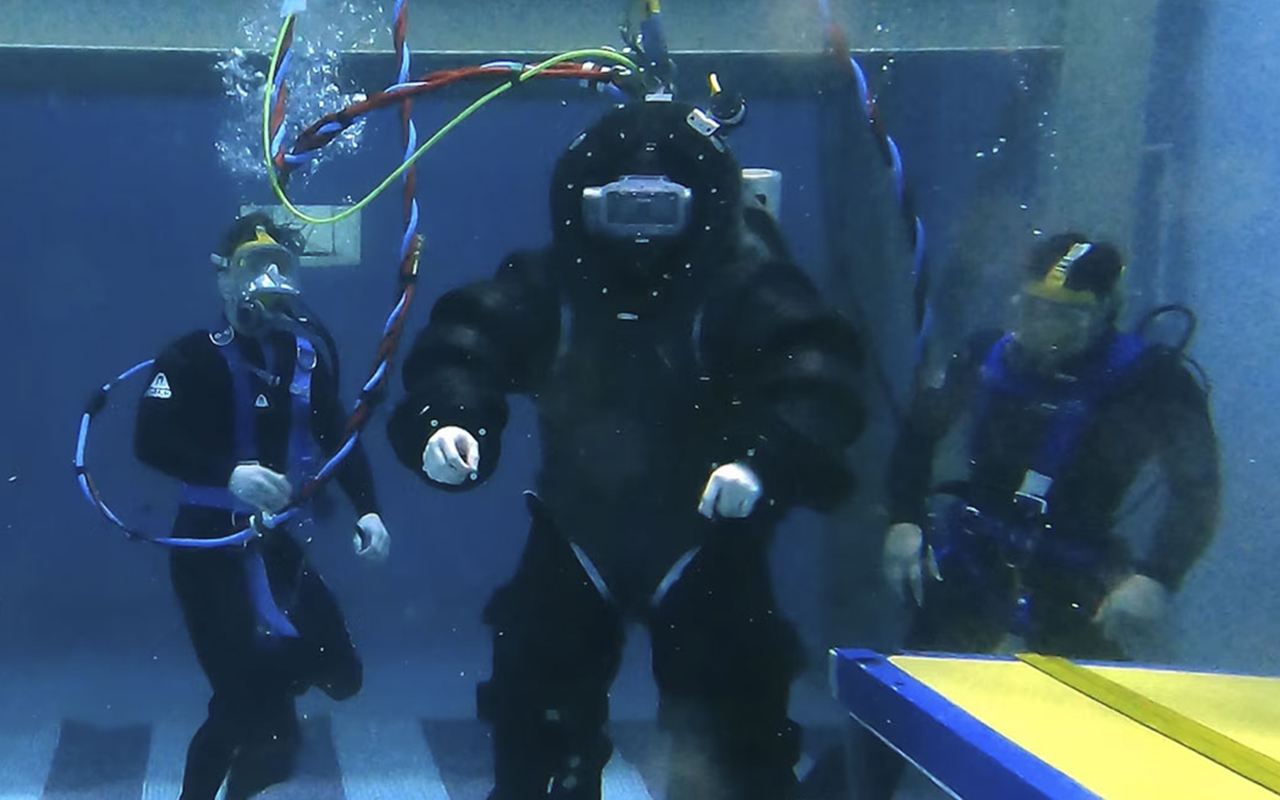

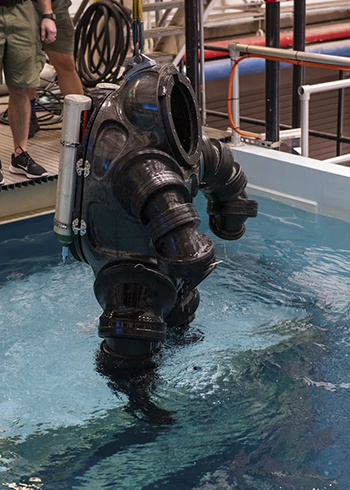

The suit features a new joint design that enables divers to perform as well those wearing wetsuits.

Human beings do not handle rapid changes in pressure well. Many people suffer from headaches when a low-pressure weather system approaches, but that’s relatively slight compared to what is felt by divers. Diving just 50 feet deep exposes the body to a pressure 2.5 times sea-level air pressure and is enough to risk decompression sickness.

Now a team of researchers working for the United States Navy have developed a suit that enables divers to work as nimble as those kitted out in skin-tight wetsuits, but without the danger posed by decompression.

Decompression sickness, more familiarly called the bends, occurs when divers ascend from working at depth for an extended period. Under high pressure, the nitrogen in the bloodstream dissolves in the liquid blood. When the pressure is released, that dissolved nitrogen begins to form bubbles; release the pressure too quickly, and enough bubbles form in various parts of the body, causing excruciating pain, neurological symptoms, and in severe cases, death.

To ward off the bends, divers who work at relatively shallow depths usually can ascend slowly enough that the nitrogen outgasses in the blood outgases gradually. But divers who spend time at great depths—such as those involved with deepwater salvage or submarine rescues—must follow a different protocol. They use a diving bell that is pressurized to match the water pressure; when the work session is over, they ride the bell up, making periodic stops to allow the nitrogen to escape their bodies. Once they reach the surface, the divers still must spend at least 90 minutes in a decompression chamber before it’s safe to return to sea level pressure.

Around five years ago, the Office of Naval Research’s Undersea Medicine and Performance and the Naval Sea Systems Command (NAVSEA) salvage diving team began a joint effort to design a diving suit that would enable work at depth without exposing divers to the sorts of pressures that would risk decompression sickness.

Marine Applications: Engineers Work to Quiet the Ocean

“Our initial goal is to develop a suit that can operate to depths of 300 feet of seawater and deeper,” said Warren Duffie, Jr., a contractor with the Office of Naval Research, on behalf of the research team behind DSEND, or the Deep Sea Expeditionary with No Decompression Suit.

Suits that fend off water pressure to maintain an internal 1 atmosphere for the diver have been in use for more than a century, but the drawback has been in the joints. Every point of articulation in the body, such as the elbow, knee, and wrist, needs a watertight, circular joint. Moving arms and legs against those joints expends energy while not providing a full range of motion. Such suits are heavy and require a large support vessel to maintain.

Another one-atmosphere alternative is a submersible, but that also requires a great deal of support while providing even less natural maneuverability.

The goal of the DSEND is to create a suit so lightweight and flexible that the diver could swim while wearing it.

“We are designing the suit to maximize natural human motion so that it allows the individual inside the suit to swim and walk on the bottom,” Duffie said. “It will be flexible and maneuverable enough to perform most underwater salvage tasks that our divers typically perform, such as crawling, clearing debris, and rigging.”

Read More: The Design Challenges of Deep-Ocean Engineering

The DSEND team, which was led by Sandra Chapman, a program officer in ONR’s Warfighter Performance Department, with management from NAVSEA’s Paul McMurtrie and Thomas Hansen from Naval Undersea Warfare Center Division Newport, developed a lightweight but hardened shell capable of withstanding 10 atmospheres of pressure, typical of what is found under 300 feet of seawater.

“The diver is never exposed to the negative physiological effects associated with deep diving, such as decompression sickness, cold, and wet exposure,” said McMurtrie in a press statement. “A diver can work for long periods of time in deep water and rapidly return to the surface.” The hope is that Navy divers using the suit can work at depth for as long as six hours at a time, compared to less than half an hour for so-called saturation divers who rely on a diving bell.

The key development was a new, hybrid joint system. In addition to the conventional circular, rotary joints, the suit features flexural, pivot-style joints. Combining those two kinds of joints enables a greater range of natural motion without risking leaks.

“Many different joint designs were attempted,” Duffie said, “but the hybrid design of rotary and pivot joints afforded the best solution to designing something that maintained flexibility at depth and allowed freedom of movement for users.”

“Many different joint designs were attempted,” Duffie said, “but the hybrid design of rotary and pivot joints afforded the best solution to designing something that maintained flexibility at depth and allowed freedom of movement for users.”

While the suit has been used successfully in a series of tests in controlled environments, it is still under development, and it may take a few years before DSEND is used in the field. One aspect still to be worked out is the glove. Fully articulated gloves that would enable divers to grip and flex their fingers are still not available. For the tests, the divers used rudimentary claws.

Jeffrey Winters is editor in chief of Mechanical Engineering magazine.

Now a team of researchers working for the United States Navy have developed a suit that enables divers to work as nimble as those kitted out in skin-tight wetsuits, but without the danger posed by decompression.

Decompression sickness, more familiarly called the bends, occurs when divers ascend from working at depth for an extended period. Under high pressure, the nitrogen in the bloodstream dissolves in the liquid blood. When the pressure is released, that dissolved nitrogen begins to form bubbles; release the pressure too quickly, and enough bubbles form in various parts of the body, causing excruciating pain, neurological symptoms, and in severe cases, death.

To ward off the bends, divers who work at relatively shallow depths usually can ascend slowly enough that the nitrogen outgasses in the blood outgases gradually. But divers who spend time at great depths—such as those involved with deepwater salvage or submarine rescues—must follow a different protocol. They use a diving bell that is pressurized to match the water pressure; when the work session is over, they ride the bell up, making periodic stops to allow the nitrogen to escape their bodies. Once they reach the surface, the divers still must spend at least 90 minutes in a decompression chamber before it’s safe to return to sea level pressure.

Around five years ago, the Office of Naval Research’s Undersea Medicine and Performance and the Naval Sea Systems Command (NAVSEA) salvage diving team began a joint effort to design a diving suit that would enable work at depth without exposing divers to the sorts of pressures that would risk decompression sickness.

Marine Applications: Engineers Work to Quiet the Ocean

“Our initial goal is to develop a suit that can operate to depths of 300 feet of seawater and deeper,” said Warren Duffie, Jr., a contractor with the Office of Naval Research, on behalf of the research team behind DSEND, or the Deep Sea Expeditionary with No Decompression Suit.

Suits that fend off water pressure to maintain an internal 1 atmosphere for the diver have been in use for more than a century, but the drawback has been in the joints. Every point of articulation in the body, such as the elbow, knee, and wrist, needs a watertight, circular joint. Moving arms and legs against those joints expends energy while not providing a full range of motion. Such suits are heavy and require a large support vessel to maintain.

Another one-atmosphere alternative is a submersible, but that also requires a great deal of support while providing even less natural maneuverability.

The goal of the DSEND is to create a suit so lightweight and flexible that the diver could swim while wearing it.

“We are designing the suit to maximize natural human motion so that it allows the individual inside the suit to swim and walk on the bottom,” Duffie said. “It will be flexible and maneuverable enough to perform most underwater salvage tasks that our divers typically perform, such as crawling, clearing debris, and rigging.”

Read More: The Design Challenges of Deep-Ocean Engineering

The DSEND team, which was led by Sandra Chapman, a program officer in ONR’s Warfighter Performance Department, with management from NAVSEA’s Paul McMurtrie and Thomas Hansen from Naval Undersea Warfare Center Division Newport, developed a lightweight but hardened shell capable of withstanding 10 atmospheres of pressure, typical of what is found under 300 feet of seawater.

“The diver is never exposed to the negative physiological effects associated with deep diving, such as decompression sickness, cold, and wet exposure,” said McMurtrie in a press statement. “A diver can work for long periods of time in deep water and rapidly return to the surface.” The hope is that Navy divers using the suit can work at depth for as long as six hours at a time, compared to less than half an hour for so-called saturation divers who rely on a diving bell.

The key development was a new, hybrid joint system. In addition to the conventional circular, rotary joints, the suit features flexural, pivot-style joints. Combining those two kinds of joints enables a greater range of natural motion without risking leaks.

While the suit has been used successfully in a series of tests in controlled environments, it is still under development, and it may take a few years before DSEND is used in the field. One aspect still to be worked out is the glove. Fully articulated gloves that would enable divers to grip and flex their fingers are still not available. For the tests, the divers used rudimentary claws.

Jeffrey Winters is editor in chief of Mechanical Engineering magazine.

.png?width=854&height=480&ext=.png)