Flexible Film Could Be Key to Better Infrared Goggles

Flexible Film Could Be Key to Better Infrared Goggles

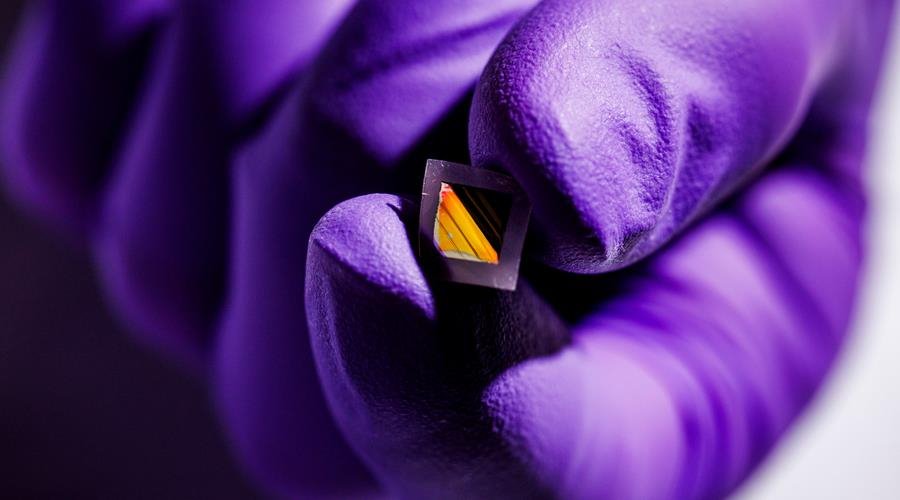

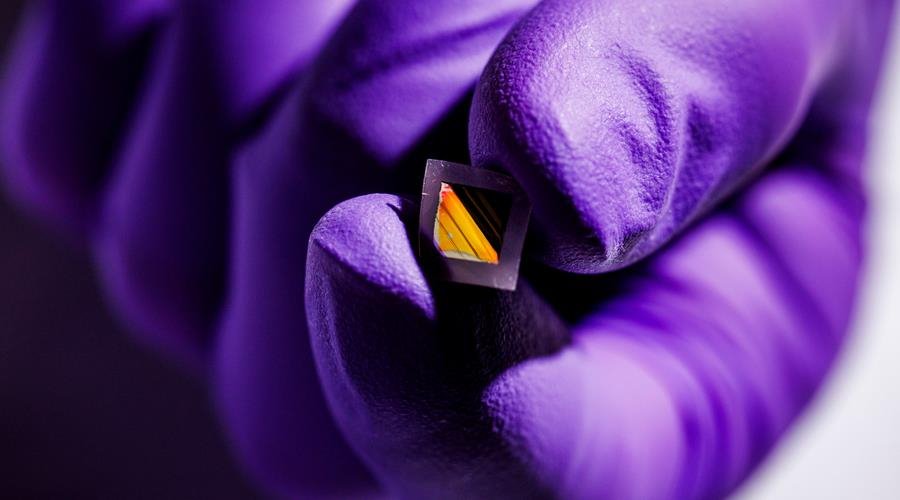

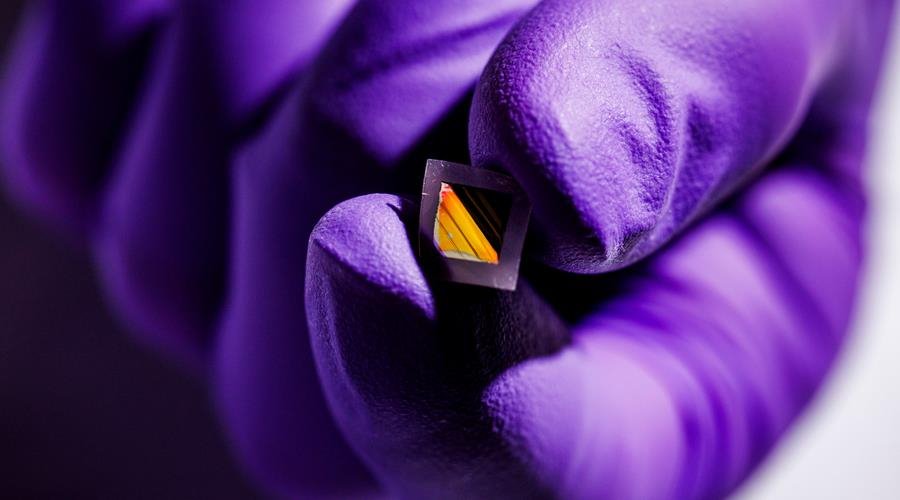

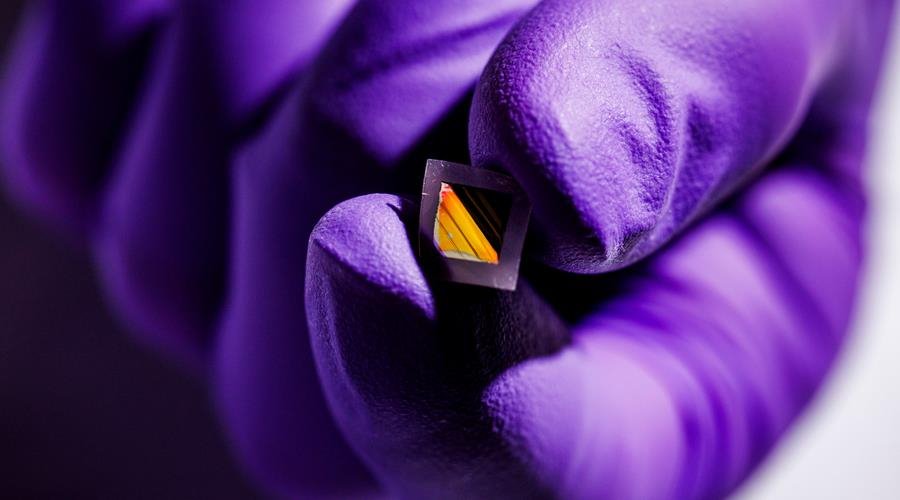

The film, at about 10-nanometers in size, senses changes in heat from objects, which helps better locate items that are typically not visible.

A thin-film for wearables, developed at the Massachusetts Institute of Technology in Cambridge and other U.S. universities, could do a better job sensing things that are not visible to the naked eye than existing infrared detectors. The film, at about 10-nanometers in size, senses changes in heat from objects, which helps better locate items that are typically not visible.

The film is thin and bendable, can be integrated into night vision goggles, and performs as well as state-of-the-art systems, which are much larger and bulkier, said Xinyuan Zhang, a researcher at MIT.

“It can get rid of all the cooling systems so that it can be very light in future wearables,” Zhang said.

The “electronic skin” could also be used in imaging systems for autonomous vehicle applications to spot items in poor weather conditions. For instance, automobiles will be able to do a better job imaging objects, cars, or pedestrians in heavy fog or during bad weather when it is dark.

“There’s very high demand in the industry because infrared imaging is very important in a lot of different applications, like vehicles or gas sensing and other things,” Zhang said.

The research provides a better and more power-efficient solution for that, Zhang said.

Researchers from MIT, the University of Wisconsin at Madison, and Rensselaer Polytechnic Institute in New York teamed up to publish a research paper that appeared in Nature.

The MIT researchers belonged to Kim’s Research Group, which has developed electronic skin for many applications. In 2022, the group developed a battery-free material that can be attached to the body and transfer health readings to smartphones.

For the latest research, the researchers developed the membrane with pyroelectric properties–which helps sense the changes in heat–using a new fabrication technique. The researchers used a technique called “atomic lift-off” to create an ultrathin film at the 10-nm size. They went on to do epitaxial growth of the film on a single crystal substrate.

Atoms were arranged in a specific pattern to build the film on the substrate. The film was grown to the size of 10 nanometers at high temperatures using radiofrequency magnetron techniques.

Mechanical Engineering Has Gone Digital

A nickel stressor layer was then attached to apply mechanical stress and exfoliate the membrane from the substrate, which just took one second. The film was then transferred to the target substrate used to make the device.

The pyroelectric material generates electricity from heat radiation. The researchers used those electric signals to measure the heat signatures and changes in temperature.

“We just attach two electrodes on it–at the top and the bottom–and measure the electric signal generated from this film,” Zhang said.

The researchers chose single-crystal materials over polycrystal or amorphous materials to get high-performance and bendability from films.

“Getting a bendable single-crystal material is extremely challenging because it needs a bulky, rigid template to grow. That’s why we’re looking for freestanding or flexible single-crystal materials,” Zhang said.

MIT’s Kim Research Group is providing several possibilities or techniques to achieve this. “Hopefully, we should get more progress in the future,” Zhang said.

The researchers took on one research challenge by creating a completely new exfoliation technique to remove the membrane from the substrate. “This lift-off method is completely new. We hope to try to exfoliate other kinds of materials by our method so that we can realize other applications, not limited just to infrared imagery,” Zhang said.

Previously, the researchers needed a chemical or some kind of two-dimensional buffer layer to peel the film off the substrate.

“In our method, we don’t need this kind of buffer layer. We just do the epitaxial growth as the regular process, and we can directly exfoliate with atomic precision,” Zhang said.

The MIT research team optimized the exfoliation method, developed the application, and created a measurement system for the pyroelectric properties. The University of Wisconsin team prepared the membrane material, and RPI provided the simulation.

The technique is patent pending, but the research isn’t complete. “To make a real IR imaging system, we need other parts like power supply and optics to focus the input light, and integrated circuits to accumulate the electric signals. We are still in the process of developing these parts,” Zhang said.

Agam Shah is a business and technology writer in Phoenix and an adjunct faculty member at the Walter Cronkite School of Journalism at Arizona State University.

The film is thin and bendable, can be integrated into night vision goggles, and performs as well as state-of-the-art systems, which are much larger and bulkier, said Xinyuan Zhang, a researcher at MIT.

“It can get rid of all the cooling systems so that it can be very light in future wearables,” Zhang said.

The “electronic skin” could also be used in imaging systems for autonomous vehicle applications to spot items in poor weather conditions. For instance, automobiles will be able to do a better job imaging objects, cars, or pedestrians in heavy fog or during bad weather when it is dark.

“There’s very high demand in the industry because infrared imaging is very important in a lot of different applications, like vehicles or gas sensing and other things,” Zhang said.

The research provides a better and more power-efficient solution for that, Zhang said.

Researchers from MIT, the University of Wisconsin at Madison, and Rensselaer Polytechnic Institute in New York teamed up to publish a research paper that appeared in Nature.

The MIT researchers belonged to Kim’s Research Group, which has developed electronic skin for many applications. In 2022, the group developed a battery-free material that can be attached to the body and transfer health readings to smartphones.

For the latest research, the researchers developed the membrane with pyroelectric properties–which helps sense the changes in heat–using a new fabrication technique. The researchers used a technique called “atomic lift-off” to create an ultrathin film at the 10-nm size. They went on to do epitaxial growth of the film on a single crystal substrate.

Atoms were arranged in a specific pattern to build the film on the substrate. The film was grown to the size of 10 nanometers at high temperatures using radiofrequency magnetron techniques.

Mechanical Engineering Has Gone Digital

A nickel stressor layer was then attached to apply mechanical stress and exfoliate the membrane from the substrate, which just took one second. The film was then transferred to the target substrate used to make the device.

The pyroelectric material generates electricity from heat radiation. The researchers used those electric signals to measure the heat signatures and changes in temperature.

“We just attach two electrodes on it–at the top and the bottom–and measure the electric signal generated from this film,” Zhang said.

The researchers chose single-crystal materials over polycrystal or amorphous materials to get high-performance and bendability from films.

“Getting a bendable single-crystal material is extremely challenging because it needs a bulky, rigid template to grow. That’s why we’re looking for freestanding or flexible single-crystal materials,” Zhang said.

MIT’s Kim Research Group is providing several possibilities or techniques to achieve this. “Hopefully, we should get more progress in the future,” Zhang said.

The researchers took on one research challenge by creating a completely new exfoliation technique to remove the membrane from the substrate. “This lift-off method is completely new. We hope to try to exfoliate other kinds of materials by our method so that we can realize other applications, not limited just to infrared imagery,” Zhang said.

Previously, the researchers needed a chemical or some kind of two-dimensional buffer layer to peel the film off the substrate.

“In our method, we don’t need this kind of buffer layer. We just do the epitaxial growth as the regular process, and we can directly exfoliate with atomic precision,” Zhang said.

The MIT research team optimized the exfoliation method, developed the application, and created a measurement system for the pyroelectric properties. The University of Wisconsin team prepared the membrane material, and RPI provided the simulation.

The technique is patent pending, but the research isn’t complete. “To make a real IR imaging system, we need other parts like power supply and optics to focus the input light, and integrated circuits to accumulate the electric signals. We are still in the process of developing these parts,” Zhang said.

Agam Shah is a business and technology writer in Phoenix and an adjunct faculty member at the Walter Cronkite School of Journalism at Arizona State University.