Energy Blog: Capturing Carbon More Efficiently

Energy Blog: Capturing Carbon More Efficiently

Direct air capture of carbon dioxide is expensive. A recent discovery could make the process more efficient and cost effective, eventually.

Efforts to decarbonize the global economy hinge on a number of interrelated actions, from reducing electricity produced by fossil fuels to altering industrial processes. The name of the game is reducing the amount of carbon dioxide emissions, and almost every industry chips in a sizeable amount of those emissions annually. That wide range means there is really no simple or single solution to reducing greenhouse gas emissions.

Energy, for instance, accounts for a bit more than 73 percent of emissions. Individually, cement and concrete are the most consumed products globally. and its production emits over 4 billion metric tons of carbon dioxide annually. Many of the largest cement producers are implementing carbon-reduction projects, with the largest, Lafargeholcim, already committing to net-zero emissions.

There will be many alterations to production processes to meet goals, but the big-ticket technologies are going to be those that capture, utilize, or store emissions gathered from large point sources. If it isn’t used onsite, the captured emissions can be compressed and stored underground or transported to be used in industrial applications. According to the International Energy Agency, there now are about 35 commercial facilities using carbon capture technologies for industrial processes, power generation, or fuel transformation, capturing some 45 million tons of CO2 annually.

Direct air capture promises to be a workhorse technology. The technology is relatively simple. Machines fitted with giant fans suck air from the atmosphere, forcing it through filters and sorbents to separate the carbon dioxide. The filters are heated to release the material, and it can then be stored or used in products.

Climeworks, a Swiss company, has perhaps the most market penetration so far with its ORCA plant in Iceland that is capturing up to 4,000 tons of CO2 per year. Powered by a local geothermal generating station, the carbon dioxide is sent underground where it mineralizes.

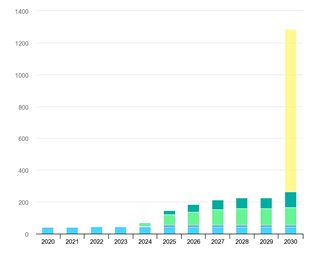

There are now 18 DAC plants operating in Canada, Europe, and the U.S., reports IEA, but governments have committed $4 billion since 2020 for development and deployment. The technology, however, is expensive, because it takes more energy to capture the carbon dioxide diluted in the atmosphere. IEA estimates that costs could fall below $100 per ton of carbon dioxide with innovation and deployment.

Become a Member: How to Join ASME

Researchers at Lehigh University recently developed a sorbent that may help meet that goal. The new copper-based sorbent could filter out carbon dioxide three times as well as those currently in use, improving performance and efficiency.

Arup Sengupta is the P.C. Rossin professor in the Department of Civil and Environmental Engineering, and co-author of the “Direct Air Capture (DAC) and Sequestration of CO2”, published recently in Science Advances. He and his team added copper to an amine-based sorbent commonly used for capture capture. Copper and nitrogen, the main component of the amine sorbent, combined to remove more carbon dioxide from the atmosphere, even if the gas is highly diluted.

It may offer another possibility for carbon disposal. In the lab, the hybrid material was brought into contact with seawater, and converted the captured carbon dioxide into baking soda. Theoretically, the alkaline material could be put in the ocean. Existing carbon capture plants must be sited where there is adequate and available underground storage. Putting the captured CO2/baking soda into ocean opens up a wealth of potential new sites for the capture plants.

Listen to Our Podcast: Carbon Capture Is Poised for Fast Growth

There’s a lot of work to be done before that can even be considered, including what might happen to oceans if large quantities of baking soda are dumped into them. The nest step is testing at a larger scale.

Discovery of the hybrid sorbent may be one of the innovations IEA is calling for to make the technology more attractive. For now it lists six priorities to ramp up direct air capture and deployment.

John Kosowatz is senior editor.

Energy, for instance, accounts for a bit more than 73 percent of emissions. Individually, cement and concrete are the most consumed products globally. and its production emits over 4 billion metric tons of carbon dioxide annually. Many of the largest cement producers are implementing carbon-reduction projects, with the largest, Lafargeholcim, already committing to net-zero emissions.

There will be many alterations to production processes to meet goals, but the big-ticket technologies are going to be those that capture, utilize, or store emissions gathered from large point sources. If it isn’t used onsite, the captured emissions can be compressed and stored underground or transported to be used in industrial applications. According to the International Energy Agency, there now are about 35 commercial facilities using carbon capture technologies for industrial processes, power generation, or fuel transformation, capturing some 45 million tons of CO2 annually.

Direct air capture promises to be a workhorse technology. The technology is relatively simple. Machines fitted with giant fans suck air from the atmosphere, forcing it through filters and sorbents to separate the carbon dioxide. The filters are heated to release the material, and it can then be stored or used in products.

Climeworks, a Swiss company, has perhaps the most market penetration so far with its ORCA plant in Iceland that is capturing up to 4,000 tons of CO2 per year. Powered by a local geothermal generating station, the carbon dioxide is sent underground where it mineralizes.

There are now 18 DAC plants operating in Canada, Europe, and the U.S., reports IEA, but governments have committed $4 billion since 2020 for development and deployment. The technology, however, is expensive, because it takes more energy to capture the carbon dioxide diluted in the atmosphere. IEA estimates that costs could fall below $100 per ton of carbon dioxide with innovation and deployment.

Become a Member: How to Join ASME

Researchers at Lehigh University recently developed a sorbent that may help meet that goal. The new copper-based sorbent could filter out carbon dioxide three times as well as those currently in use, improving performance and efficiency.

Arup Sengupta is the P.C. Rossin professor in the Department of Civil and Environmental Engineering, and co-author of the “Direct Air Capture (DAC) and Sequestration of CO2”, published recently in Science Advances. He and his team added copper to an amine-based sorbent commonly used for capture capture. Copper and nitrogen, the main component of the amine sorbent, combined to remove more carbon dioxide from the atmosphere, even if the gas is highly diluted.

It may offer another possibility for carbon disposal. In the lab, the hybrid material was brought into contact with seawater, and converted the captured carbon dioxide into baking soda. Theoretically, the alkaline material could be put in the ocean. Existing carbon capture plants must be sited where there is adequate and available underground storage. Putting the captured CO2/baking soda into ocean opens up a wealth of potential new sites for the capture plants.

Listen to Our Podcast: Carbon Capture Is Poised for Fast Growth

There’s a lot of work to be done before that can even be considered, including what might happen to oceans if large quantities of baking soda are dumped into them. The nest step is testing at a larger scale.

Discovery of the hybrid sorbent may be one of the innovations IEA is calling for to make the technology more attractive. For now it lists six priorities to ramp up direct air capture and deployment.

- Demonstrate DAC at scale as a priority.

- Foster innovation across the value chain.

- Identify and develop carbon dioxide storage.

- Develop internationally agreed approaches to DAC certification and accounting.

- Build international cooperation for accelerated deployment.

John Kosowatz is senior editor.

.png?width=854&height=480&ext=.png)