Capturing VOCs in a Container

Capturing VOCs in a Container

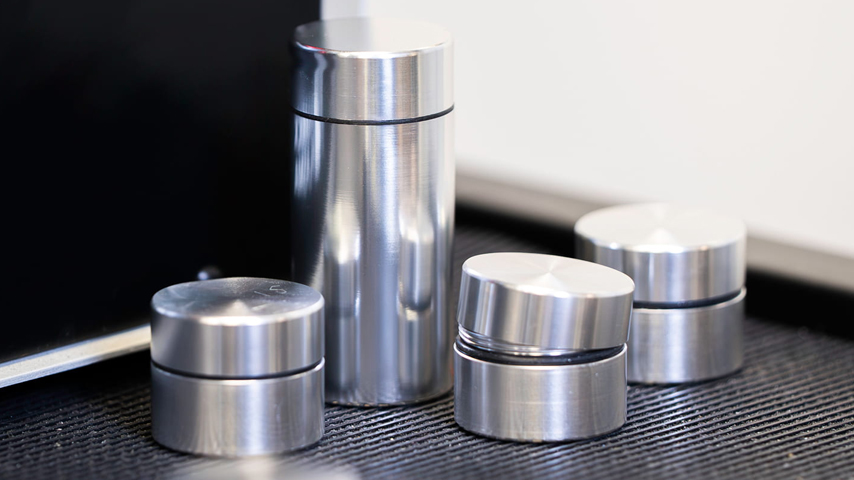

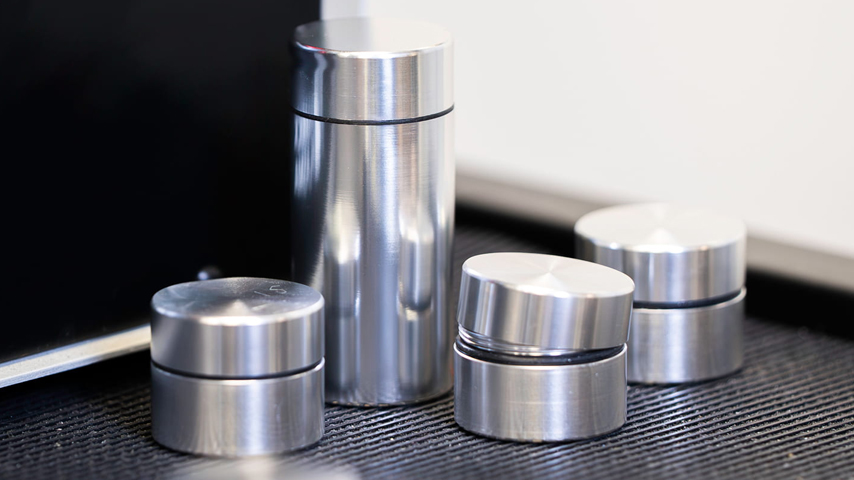

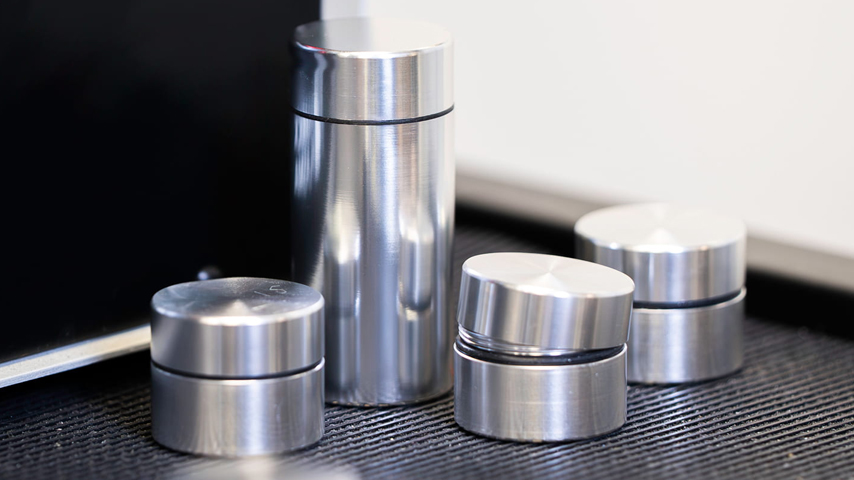

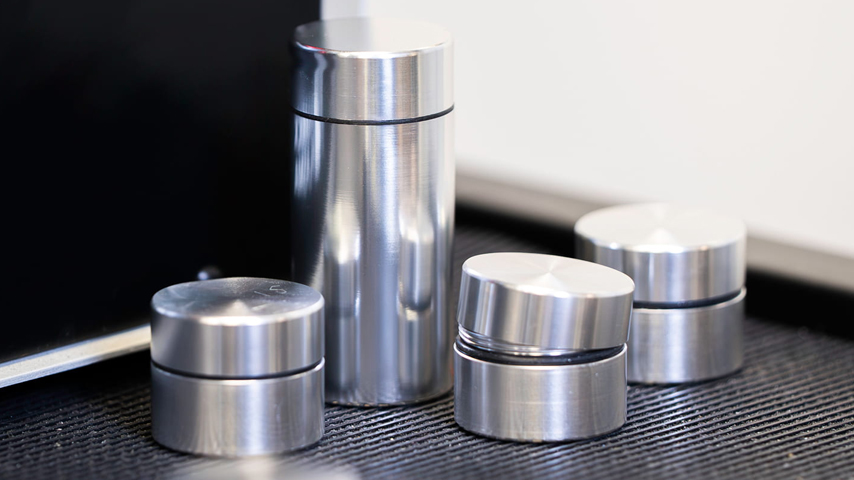

Mechanical engineers in Rice University’s Preston Innovation Laboratory have created containers that can keep volatile organic compounds from accumulating on the surfaces of stored nanomaterials.

A half century ago, M.L. White, a researcher at Bell Telephone Laboratories, Inc., in Allentown, Pa., proposed a unique clean storage strategy to deal with contamination build-up on quartz crystal surfaces, a material that at the time was used in a variety of electronic applications. Daniel Preston, an assistant professor at Rice University’s Department of Mechanical Engineering said the approach, based on using a large pre-cleaned surface to capture carbon contaminants, was ahead of its time.

“This researcher put a lot of aluminum shot inside of a container,” Preston explained. “The shot had been pre-cleaned and placed inside the container to enable a large internal surface area of clean material. It basically acted as a sacrificial surface, grabbing contaminants out of the air, keeping the materials stored inside the container clean.”

Despite White’s success, his method for cleaning was largely ignored for decades. Now, Preston and colleagues, including doctoral student Zhen Liu, have built upon White’s work, using modern nanotechnology and cleaning techniques to create innovative aluminum containers to keep volatile organic compounds (VOCs) from accumulating upon stored nanomaterials.

VOCs are remarkably common. These carbon-based pollutants come from a variety of products commonly used in households and the laboratory: paints, office supplies, crafting materials, and cleaning products. Liu said these contaminants form a carbon layer on nanomaterials, potentially interfering with their performance.

“Traditionally, people have tried to store materials in a container. They might use a Petri dish to try and capture VOCs or they might use a desiccator that can pump the air out of a container to keep it in low-vacuum conditions. But those traditional methods are not very effective,” she said. “Usually, the interior surface of the container wall is covered with the VOC contaminants, which can dissolve away from the wall and make the sample materials inside the containers dirty again.”

Become a Member: How to Join ASME

This is of critical concern, added Preston as so many researchers who are working to develop new nanomaterials don’t measure the impact of contaminants on different applications.

“People have to pay more attention to the sources of contamination and how that influences the results of the fundamental research they are doing or the systems or devices they are developing,” he said. “VOC contamination is a pretty ubiquitous problem across nanomanufacturing. People, overall, need to be more cognizant of what that might be doing in their work, and they also need effective solutions to deal with it.”

“This high surface area is created by an inexpensive and scalable method, using a hot water treatment on the aluminum to create these micro- and nano-hierarchical structures,” said Liu. “We then use advanced cleaning methods like plasma cleaning to create a clean high surface area that sacrifices itself to hold contaminants so the other materials inside will be kept clean.”

In initial tests, the group demonstrated that this approach works well, and the containers can be recleaned and reused as needed. The research team also developed a theoretical model to help them better understand what was happening inside the containers. That model will help them optimize the contaminant capture and storage capabilities of the system in the future.

More for You: 5 Ways Nanotechnology Affects Everyday Life

“We could extend our work to try other materials inside the container that might be more effective than aluminum to capture contaminants,” said Liu. “We can also explore storage methods that may be more helpful in mitigating contaminants beyond VOCs.”

For now Preston said he hopes that researchers in material science as well as industries using nanomanufacturing take a good look at how contaminants may be influencing their results and consider new ways to manage VOCs. He said one of the best things about his team’s approach to VOC capture is that it should be easy to scale containers for a variety of different applications.

“The exciting thing about this approach is that it’s truly scalable and size and geometric agnostic,” he explained. “For example, if a researcher is working with small samples of new materials in the laboratory setting, they can use containers similar to the ones we’ve already tested in detail. If this approach is going to be used in an industrial application, you can imagine a container that is the size of a room that can capture VOCs. The techniques that we use to make these ultra-clean storage containers really are independent of the scale at which you make them.”

Kayt Sukel is a science and technology writer in Houston.

“This researcher put a lot of aluminum shot inside of a container,” Preston explained. “The shot had been pre-cleaned and placed inside the container to enable a large internal surface area of clean material. It basically acted as a sacrificial surface, grabbing contaminants out of the air, keeping the materials stored inside the container clean.”

Despite White’s success, his method for cleaning was largely ignored for decades. Now, Preston and colleagues, including doctoral student Zhen Liu, have built upon White’s work, using modern nanotechnology and cleaning techniques to create innovative aluminum containers to keep volatile organic compounds (VOCs) from accumulating upon stored nanomaterials.

VOCs are remarkably common. These carbon-based pollutants come from a variety of products commonly used in households and the laboratory: paints, office supplies, crafting materials, and cleaning products. Liu said these contaminants form a carbon layer on nanomaterials, potentially interfering with their performance.

“Traditionally, people have tried to store materials in a container. They might use a Petri dish to try and capture VOCs or they might use a desiccator that can pump the air out of a container to keep it in low-vacuum conditions. But those traditional methods are not very effective,” she said. “Usually, the interior surface of the container wall is covered with the VOC contaminants, which can dissolve away from the wall and make the sample materials inside the containers dirty again.”

Become a Member: How to Join ASME

This is of critical concern, added Preston as so many researchers who are working to develop new nanomaterials don’t measure the impact of contaminants on different applications.

“People have to pay more attention to the sources of contamination and how that influences the results of the fundamental research they are doing or the systems or devices they are developing,” he said. “VOC contamination is a pretty ubiquitous problem across nanomanufacturing. People, overall, need to be more cognizant of what that might be doing in their work, and they also need effective solutions to deal with it.”

Increasing the surface area

Building off White’s proposed approach, Preston, Liu, and colleagues developed new ultraclean containers. The group expanded the surface area of the container’s interior aluminum wall through the creation of microscopic and nanoscopic peaks and valleys, making it easier for VOCs to attach to the metal atoms inside when the container is sealed.“This high surface area is created by an inexpensive and scalable method, using a hot water treatment on the aluminum to create these micro- and nano-hierarchical structures,” said Liu. “We then use advanced cleaning methods like plasma cleaning to create a clean high surface area that sacrifices itself to hold contaminants so the other materials inside will be kept clean.”

In initial tests, the group demonstrated that this approach works well, and the containers can be recleaned and reused as needed. The research team also developed a theoretical model to help them better understand what was happening inside the containers. That model will help them optimize the contaminant capture and storage capabilities of the system in the future.

More for You: 5 Ways Nanotechnology Affects Everyday Life

“We could extend our work to try other materials inside the container that might be more effective than aluminum to capture contaminants,” said Liu. “We can also explore storage methods that may be more helpful in mitigating contaminants beyond VOCs.”

For now Preston said he hopes that researchers in material science as well as industries using nanomanufacturing take a good look at how contaminants may be influencing their results and consider new ways to manage VOCs. He said one of the best things about his team’s approach to VOC capture is that it should be easy to scale containers for a variety of different applications.

“The exciting thing about this approach is that it’s truly scalable and size and geometric agnostic,” he explained. “For example, if a researcher is working with small samples of new materials in the laboratory setting, they can use containers similar to the ones we’ve already tested in detail. If this approach is going to be used in an industrial application, you can imagine a container that is the size of a room that can capture VOCs. The techniques that we use to make these ultra-clean storage containers really are independent of the scale at which you make them.”

Kayt Sukel is a science and technology writer in Houston.

Pulse of the Profession: Career-Ready Soft Skills

The supremacy of technical knowledge is softening, with a growing emphasis on multi-faceted skills.