Hafnium Oxide Could Boost Semiconductor Performance

Hafnium Oxide Could Boost Semiconductor Performance

Engineers have found that oxygen vacancies in the structure of hafnium oxide are important for increasing and maintaining the ferroelectric qualities of this potential integrated circuit material.

In an effort to flatten this energy demand curve, Jon Ihlefeld, associate professor of materials science and engineering at the University of Virginia in Charlottesville, and his multifunctional thin film research group, are investigating ferroelectric hafnium oxide as a material system that could allow the co-location of computation and memory on a single chip, thereby saving energy.

Become a Member: How to Join ASME

Hafnium oxide holds promise for providing nonvolatile memory that can be integrated directly into the circuit. However, there is a key downside: In its natural state, hafnium oxide is not ferroelectric. Ihlefeld’s group is intent on discovering a process that will make hafnium wholly ferroelectric.

Manipulation through sputtering

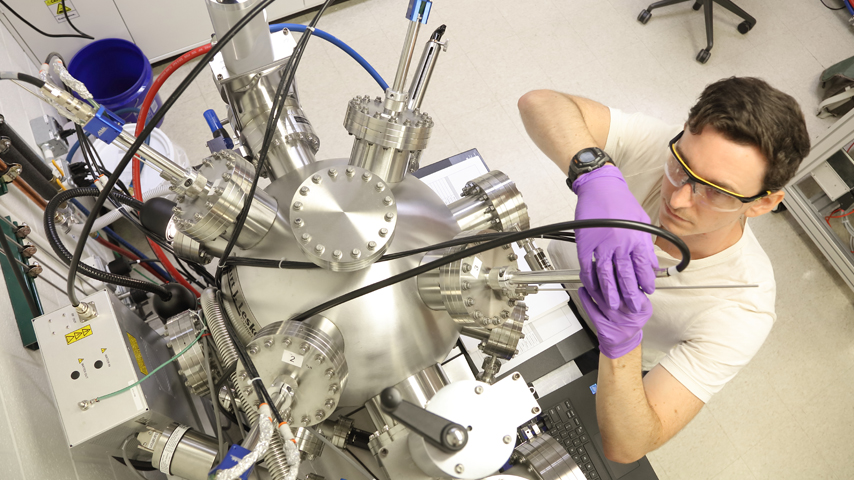

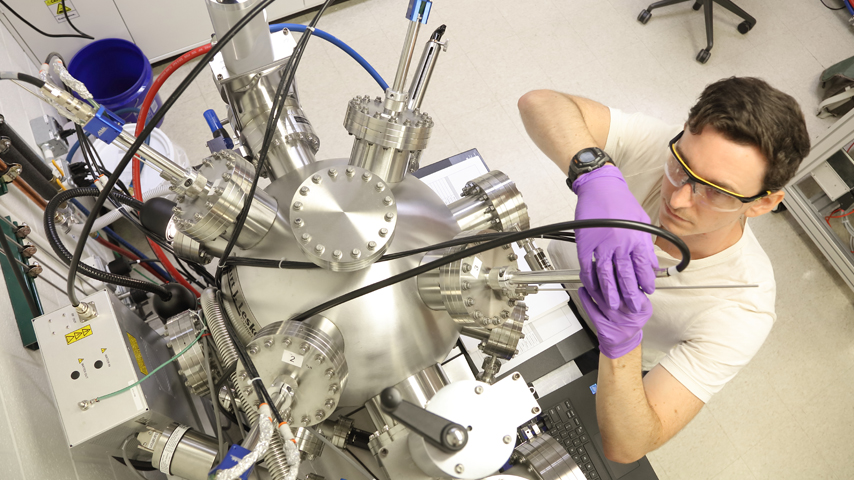

Hafnium oxide’s atoms can be manipulated to produce and hold a ferroelectric phase, or structure. When an electric field is applied and released, it remembers the orientation of applied field. However, obtaining this ferroelectric phase is extremely challenging. Based upon some computational predictions from a group in Germany that showed grain size was a critical parameter in stabilizing the ferroelectric phase, Ihlefeld decided to try to sputter-deposit hafnia with a relatively new technique called high power impulse magnetron sputtering (HiPIMS), which had previously been shown to enable preparation of extremely fine and uniform grain sizes in in refractory materials.

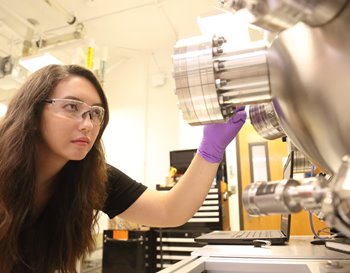

“We were sputtering from a metallic hafnium target and utilizing oxygen in the plasma gas to oxidize the deposit,” said Ihlefeld. “As Samantha prepared films under a small range of differing oxygen contents in the plasma, she observed that the phases present varied greatly. With extensive microstructural characterization, she found that the films had identical microstructures—that is, the grain sizes were all the same, but the phases were different.”

After rigorous chemical characterization, which included X-ray photoelectron spectroscopy, electron energy loss spectroscopy, and positron annihilation spectroscopy on her hafnia films, she discovered the oxygen content differed greatly for her films that had formed different phases. “Furthermore,” he continued, “she found that the oxygen vacancies present were mostly neutrally charged. This was a new observation for the field.”

More for You: How Gallium Nitride Enables Smaller, More Efficient Power Supplies

Having missing oxygen atoms in certain places can actually help stabilize the ferroelectric phase. The natural, non-ferroelectric state can tolerate a number of these oxygen vacancies, but not as many as needed to stabilize the ferroelectric phase. Jaszewski’s experiments show that oxygen vacancies may be one of the most important parameters to stabilize the ferroelectric phase of hafnium oxide.

“There are several unique aspects of our research,” said Ihlefeld. “We were the first to apply HiPIMS to the preparation of hafnia for electronic memory applications. Second, we were the first to show that grain size is not a primary factor controlling phase stability, but that oxygen vacancy concentration is vitally important. Third, we showed the oxygen vacancy concentrations needed to stabilize the ferroelectric phase are far greater than previously thought. This last observation was a result of us measuring not just ionized vacancies, but also charge neutral vacancies.”

Next steps

More research needs to be done to understand how oxygen vacancies exist and how they affect the ferroelectric properties of hafnium oxide. Also, now that the team understands how important oxygen vacancies are, it is ready to develop strategies to make sure that they do not move during use of the device.

“For example, if the vacancies ionize, then they can drift under the applied electric fields used to write and read the memory state,” said Ihlefeld. “This can lead to accumulation of vacancies near interfaces and even cause the ferroelectric phase to transition to a non-ferroelectric phase.”

It is also important to find ways to keep the vacancies from ionizing. If they remain charge-neutral, there will be no force on them that would result in their motion under an applied electric field and they should remain in their original position.

“This landmark study explains, in part, why ferroelectric hafnium oxide exists and how it stabilizes,” Ihlefeld said. “Based on these new findings, we can engineer hafnium oxide thin films to be even more stable and perform even better in an actual application. By doing this fundamental research we can help semiconductor firms understand the origin of problems and how to prevent them in future production lines.”

Mark Crawford is a technology writer in Corrales, N.M.