Future-Ready: An Exosuit Designed to Grow with Children

Future-Ready: An Exosuit Designed to Grow with Children

.jpg?width=850&height=566&ext=.jpg)

.jpg?width=850&height=566&ext=.jpg)

A next-generation pediatric exosuit designed to grow with children, supporting movement, play, and development at every stage, while adapting to their changing needs and promoting long-term mobility.

The National Science Foundation’s (NSF) BRAIN Center at the University of Houston is spearheading a groundbreaking initiative: the development of a soft pediatric exosuit. This project addresses the unique challenges of designing for children with conditions such as cerebral palsy.

But creating technology that can grow with a child is not as simple as scaling down existing technology; it’s about a fundamental reimagining of exosuit design. For this reason, it has not gotten the same funding and attention as other adult-focused exosuit projects.

“Technology for pediatrics is lagging,” said Jose Luis Contreras-Vidal, the BRAIN Center’s director. “But a child’s brain and body are very plastic—they can adapt and learn at any age and stage in their development, so it is never too early to start working with them.”

He continued, “The MyoStep is a garment-based design that can be adjusted to the changing bodies and needs of its wearers. At the core of what makes MyoStep so versatile is the innovative application of soft robotics, specifically electroactive polymer (EAP)-based artificial muscles.”

“The soft actuating material, which is dielectric elastomer, has almost the same energy density as human muscle,” Zheng Chen said, professor of mechanical and aerospace engineering and a key researcher on the team.

Unlike rigid motors, these EAPs also provide a compliant force that more closely mimics natural human muscle contractions. These crucial properties mean the artificial muscles can generate significant force without adding excessive weight to the device, making it easier for a child to wear it.

One of the biggest challenges overcome by the team was learning how to safely apply high voltage for the actuation of the EAPs. After many iterations, they landed on a layered “sandwich” structure, which insulates the EAPs and protects the wearer from harm, making the technology ‘kid friendly,’ Chen stated.

They also had to learn how to place the material at the right spot so it would generate sufficient force while still keeping the fabric taut. To achieve this effectively, Contreras-Vidal enlisted the assistance of Paige A. Willson, a fashion designer with expertise in costume design and technology.

Relevant Reads: Robot Aims to Help Children with Cerebral Palsy

“She has a very unique understanding of the body and how it moves and of the types of fabric children would actually be comfortable in,” Contreras-Vidal said.

The MyoStep uses technical fabrics that are stretchable in two or more dimensions, providing dynamic compression and support. This is particularly important for children with cerebral palsy and could possibly reduce the rate of structural abnormalities over time, potentially improving long-term health outcomes.

The power source for the exosuit is another area of novel engineering. Francisco C. Robles Hernandez, professor of mechanical engineering technology, explained the goal of the device is to be battery free. Through thermo-responsive smart materials, they aim for continuous, passive actuation simply from the child’s body heat. While some components may require external power, the team is committed to portability.

“Our goal is for it to power very naturally and offer consistent and gentle force over long sustained periods of time, much like braces work on teeth,” Robles said.

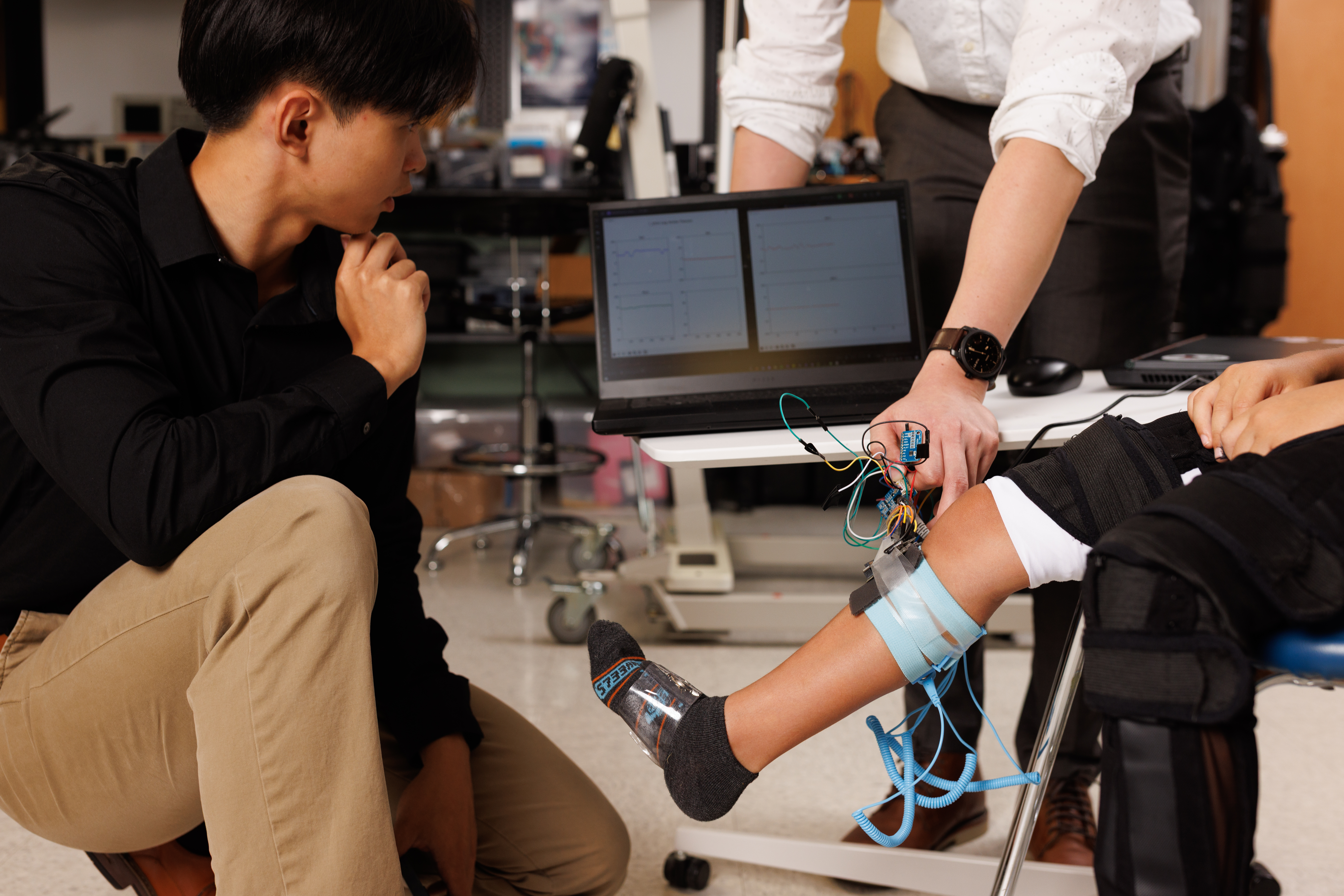

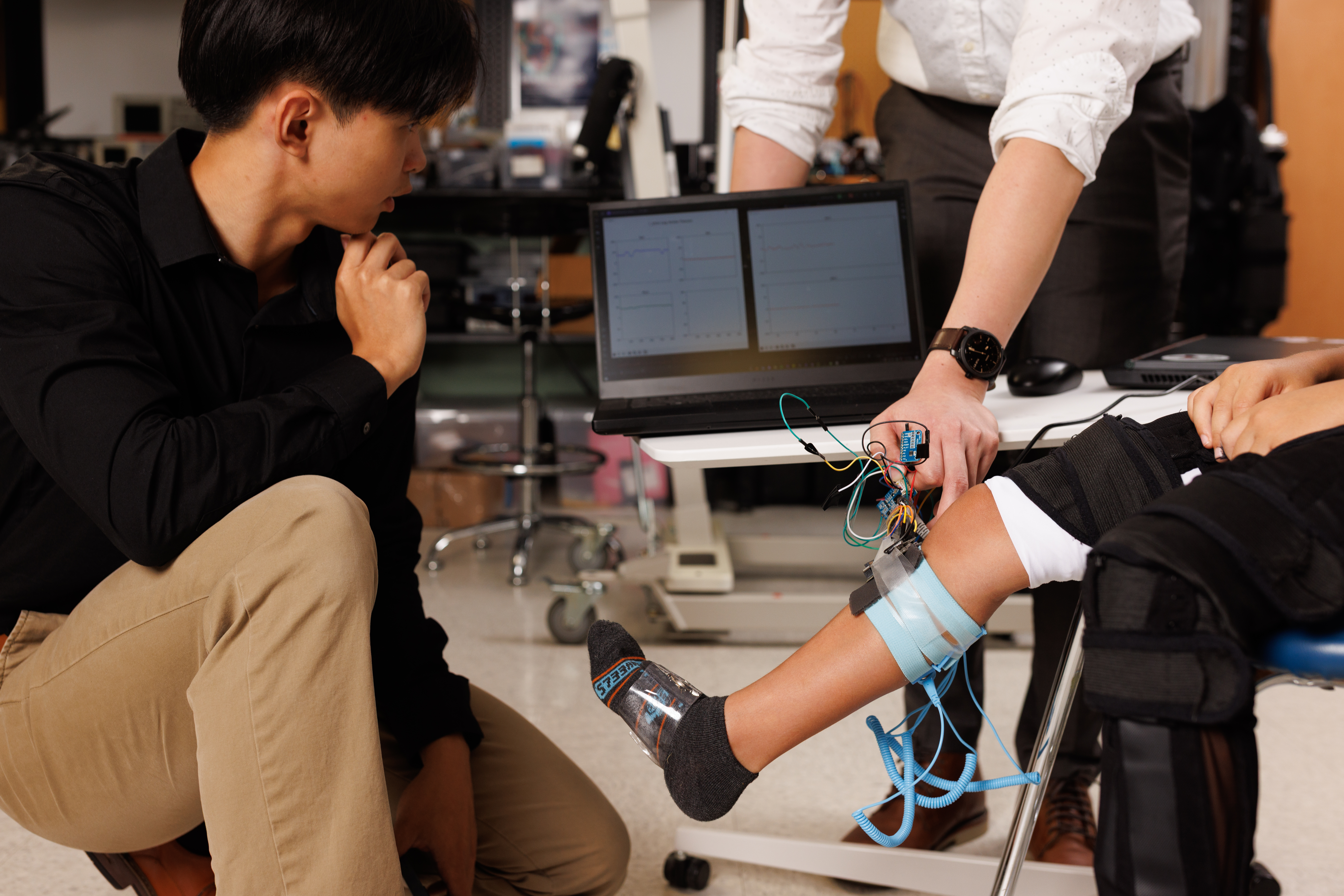

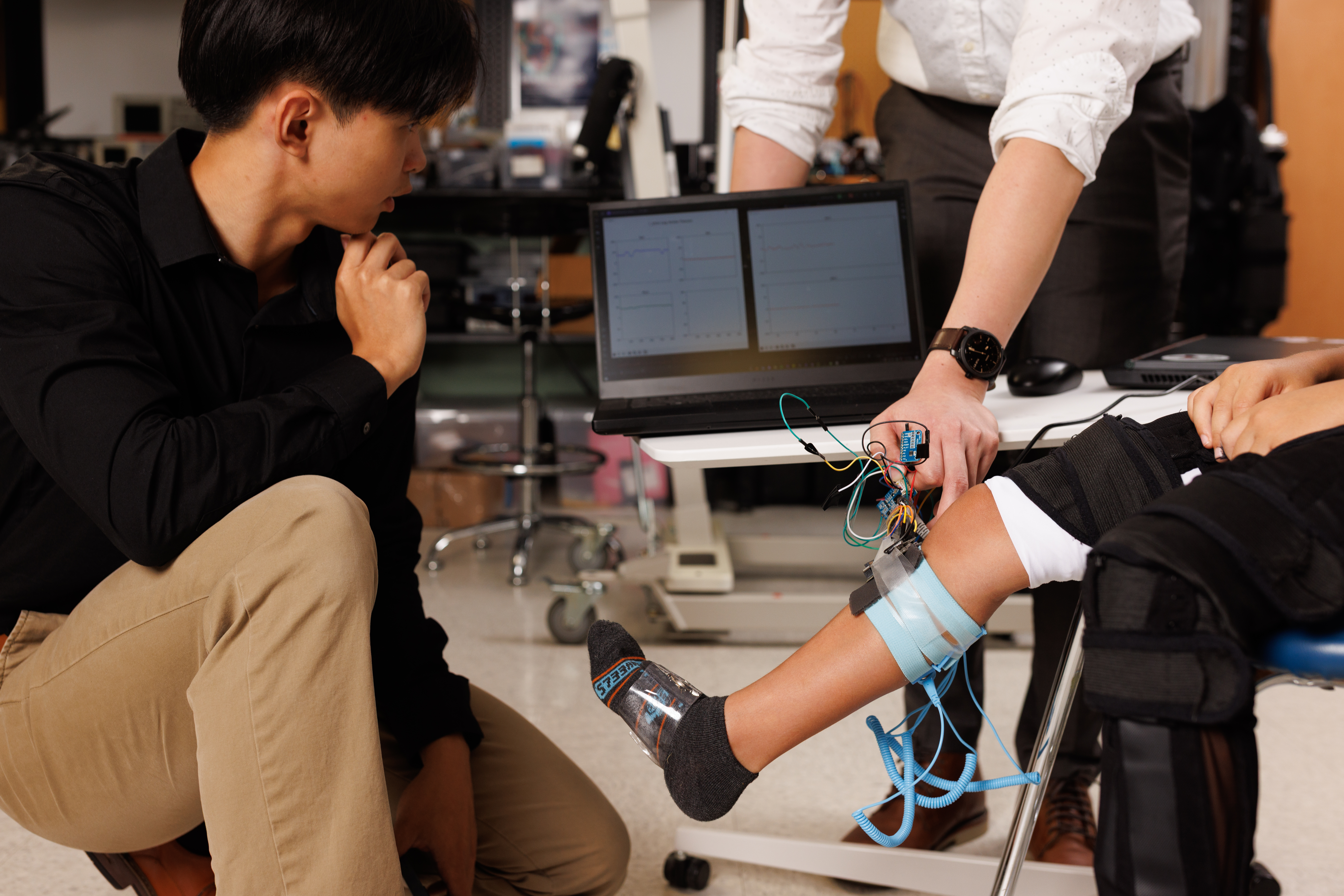

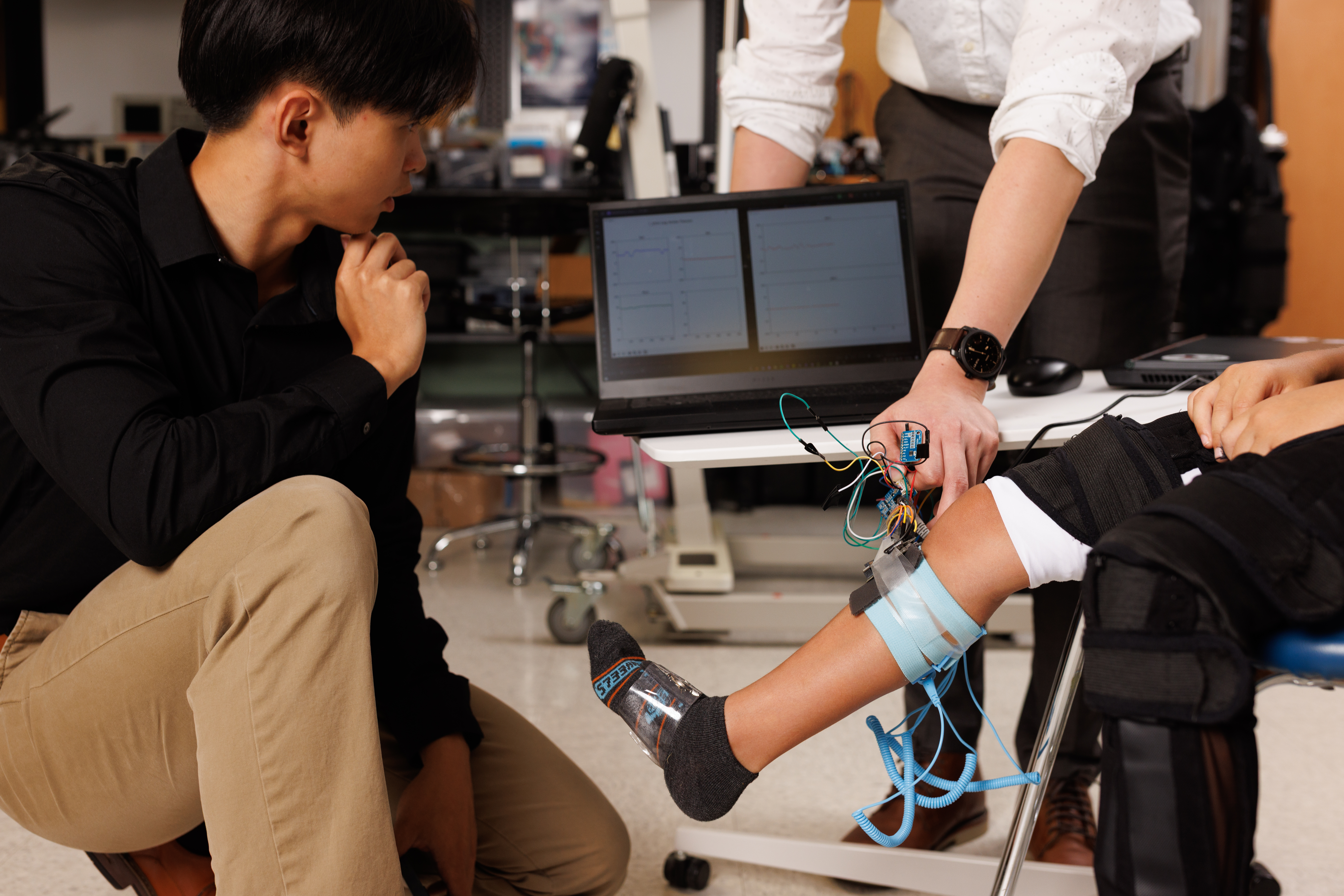

The project remains in active development, with several exciting next steps, including developing standardized methodology for designing with EAPs. The integration of advanced data collection and analytics is another future direction.

ASME Membership Benefits

Contreras-Vidal added, “We are measuring kinematics and kinetics, and producing data sets that are new to our current understanding of conditions like cerebral palsy. The outputs from this sensor network may lead to new types of diagnostics.”

This rich data will inform and validate the machine learning approaches being developed by the team to simulate and customize designs for individual children, reducing the need for extensive physical testing.

As a Class II medical device, the MyoStep will likely require special controls and rigorous evaluation by the FDA. With this in mind, the team plans to expand recruitment to gather more diverse data across age, gender, and backgrounds, further refining the device’s usability and effectiveness.

Looking even further ahead, Contreras-Vidal envisions the integration of brain-computer interfaces that would detect the wearer’s intent and use those signals to control the device. This would improve the feeling of autonomy the wearer has and reinforce the brain’s top-down control signals with real-time feedback.

Driven by cutting-edge materials science, biomechanical insight, and a profound commitment to user-centric design, the MyoStep is laying the foundation for a new era of rehabilitation robotics.

Cassandra Kelly is a technology writer in Columbus, Ohio.

But creating technology that can grow with a child is not as simple as scaling down existing technology; it’s about a fundamental reimagining of exosuit design. For this reason, it has not gotten the same funding and attention as other adult-focused exosuit projects.

“Technology for pediatrics is lagging,” said Jose Luis Contreras-Vidal, the BRAIN Center’s director. “But a child’s brain and body are very plastic—they can adapt and learn at any age and stage in their development, so it is never too early to start working with them.”

He continued, “The MyoStep is a garment-based design that can be adjusted to the changing bodies and needs of its wearers. At the core of what makes MyoStep so versatile is the innovative application of soft robotics, specifically electroactive polymer (EAP)-based artificial muscles.”

“The soft actuating material, which is dielectric elastomer, has almost the same energy density as human muscle,” Zheng Chen said, professor of mechanical and aerospace engineering and a key researcher on the team.

Artificial muscles that move like the real thing

Unlike rigid motors, these EAPs also provide a compliant force that more closely mimics natural human muscle contractions. These crucial properties mean the artificial muscles can generate significant force without adding excessive weight to the device, making it easier for a child to wear it.

One of the biggest challenges overcome by the team was learning how to safely apply high voltage for the actuation of the EAPs. After many iterations, they landed on a layered “sandwich” structure, which insulates the EAPs and protects the wearer from harm, making the technology ‘kid friendly,’ Chen stated.

They also had to learn how to place the material at the right spot so it would generate sufficient force while still keeping the fabric taut. To achieve this effectively, Contreras-Vidal enlisted the assistance of Paige A. Willson, a fashion designer with expertise in costume design and technology.

Relevant Reads: Robot Aims to Help Children with Cerebral Palsy

“She has a very unique understanding of the body and how it moves and of the types of fabric children would actually be comfortable in,” Contreras-Vidal said.

The MyoStep uses technical fabrics that are stretchable in two or more dimensions, providing dynamic compression and support. This is particularly important for children with cerebral palsy and could possibly reduce the rate of structural abnormalities over time, potentially improving long-term health outcomes.

The power source for the exosuit is another area of novel engineering. Francisco C. Robles Hernandez, professor of mechanical engineering technology, explained the goal of the device is to be battery free. Through thermo-responsive smart materials, they aim for continuous, passive actuation simply from the child’s body heat. While some components may require external power, the team is committed to portability.

“Our goal is for it to power very naturally and offer consistent and gentle force over long sustained periods of time, much like braces work on teeth,” Robles said.

The project remains in active development, with several exciting next steps, including developing standardized methodology for designing with EAPs. The integration of advanced data collection and analytics is another future direction.

ASME Membership Benefits

Contreras-Vidal added, “We are measuring kinematics and kinetics, and producing data sets that are new to our current understanding of conditions like cerebral palsy. The outputs from this sensor network may lead to new types of diagnostics.”

This rich data will inform and validate the machine learning approaches being developed by the team to simulate and customize designs for individual children, reducing the need for extensive physical testing.

Shaping the future of pediatric rehabilitation robotics

As a Class II medical device, the MyoStep will likely require special controls and rigorous evaluation by the FDA. With this in mind, the team plans to expand recruitment to gather more diverse data across age, gender, and backgrounds, further refining the device’s usability and effectiveness.

Looking even further ahead, Contreras-Vidal envisions the integration of brain-computer interfaces that would detect the wearer’s intent and use those signals to control the device. This would improve the feeling of autonomy the wearer has and reinforce the brain’s top-down control signals with real-time feedback.

Driven by cutting-edge materials science, biomechanical insight, and a profound commitment to user-centric design, the MyoStep is laying the foundation for a new era of rehabilitation robotics.

Cassandra Kelly is a technology writer in Columbus, Ohio.

.jpg?width=850&height=566&ext=.jpg)

.jpg?width=850&height=566&ext=.jpg)