Concrete Key to Taller Wind Turbines

Concrete Key to Taller Wind Turbines

Images: Iowa State University

Standard wind turbine towers are routinely designed to be 80 meters tall because that is about the maximum height that can be achieved with the limits of the highway system for transporting and delivering major parts.

Of course, taller towers would allow the capture of faster, more sustainable wind energy. To this end, wind energy companies are exploring other design options that would enable hub heights of 100 meters or higher. Steel would not be the material of choice because the increased base dimensions for taller steel towers would require the bottom section to be transported in multiples pieces and assembled onsite, adding considerable time and cost to the operation.

To overcome this challenge, researchers at Iowa State University have developed a new tower design that uses concrete, not steel, as the construction material. Concrete towers could reach heights of 100 meters and utilize the current transportation system for delivery of parts.

Three High-Strength Materials

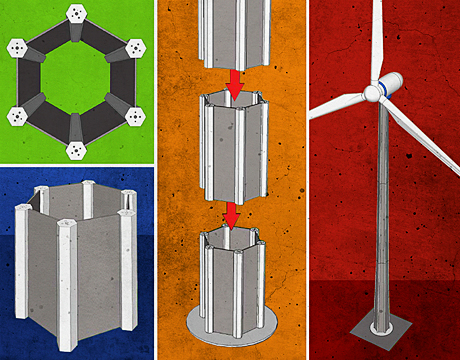

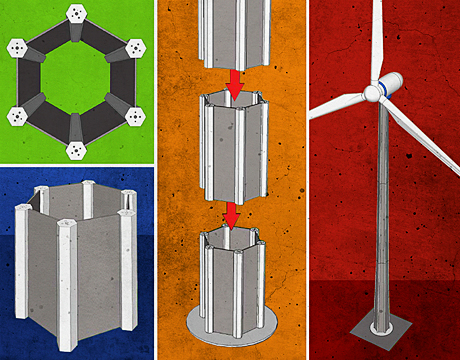

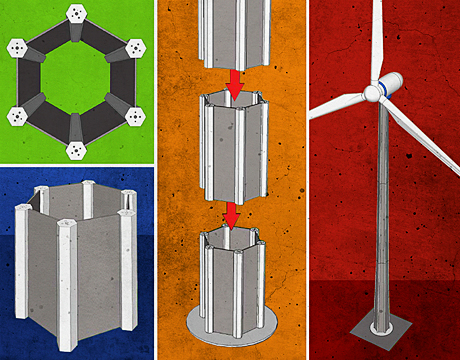

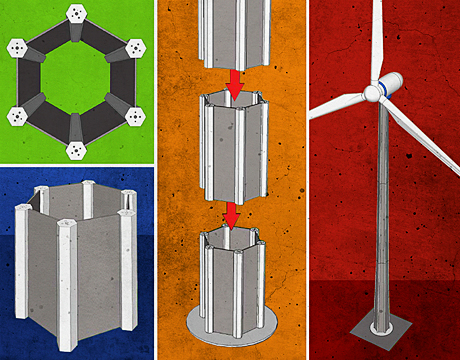

Sri Sritharan, professor of civil, construction, and environmental engineering at Iowa State University in Ames, has proposed a new tower concept that utilizes precast ultra-high-performance concrete (UHPC), high-strength concrete (HC) segments, and high-strength prestressing strands. Sritharan has provided three tower designs that have different connection systems (high-strength bolts, post-tensioning, and in-situ UHPC) between the precast segments:

• High-strength (HC) columns, UHPC panels, and bolted connections—bolted connections are dry and require no curing.

• High-strength (HC) columns, UHPC panels, post-tensioned connections—post-tensioning connections can easily eliminate or control cracks on the panels and have more tolerance compared to bolted connections.

• High-strength (HC) columns, HC panels, UHPC in-situ joints—these joints provide even more tolerance and could be more cost-effective.

"The design of steel towers is governed by fatigue load, which is tied to duration of life chosen for the towers, typically about 20 to 25 years," says Sritharan. "Concrete towers are not controlled by fatigue; UHPC provides excellent durability properties. Targeting a concrete tower for a lifespan of 40 to 50 years is not unreasonable."

Each tower design consists of six exterior columns. Concrete panels completely enclose the tower interior and allow the tower to act as a composite structure during loading, without the need to be rigidly connected to the foundation. The columns and panels are segmented into manageable sizes for easy transportation and assembly on site. Each design reaches a hub height of 100 meters and is ready for potential field implementation.

Future Possibilities

"I believe the steel-shell concept for towers has reached its height limits," says Sritharan. "While we can push the height limit incrementally, tower design needs some transformative changes to go much higher. Our concept does just this: We are basically starting at 100 meters and can easily go higher. We are also eliminating transportation challenges and high costs associated with transportation of steel towers."

Sritharan stresses that many mechanical engineers don't consider concrete when it comes to solving structural problems. This is in partly due to the lower strength of concrete compared to steel and their inexperience with concrete. "With the introduction of UHPC with 200-MPa strength, we have a material that has the best of both concrete and steel, but needs newer design concepts to be fully utilized," he says.

Part of this inspiration can be gained by looking at other industries and learning from their experiences with innovative, cost-effective solutions. For example, the building industry uses plenty of prefabricated components today to reduce construction costs and improve quality. "An 80-meter tower compares to a 21-story building, but special transportation is not needed when the building is constructed using prefabricated modules," says Sritharan.

The next step is installing a prototype tower in the field. Sritharan is confident that his new design will prove to be better than today's technology for taller towers.

"Our system will save costs on transportation, raw materials, and construction," he says. "Construction costs will also come down as more towers are built. Our tower design is more durable than steel and can be easily tailored to meet any turbine size and tower height."

Mark Crawford is an independent writer.

With the introduction of ultra-high performance concrete (UHPC) with 200 MPa strength, we have a material that has the best of both concrete and steel, but needs newer design concepts to be fully utilized.Prof. Sri Sritharan, Iowa State University

.png?width=854&height=480&ext=.png)