A Safe, Cold-Sintered, Solid-State Battery

A Safe, Cold-Sintered, Solid-State Battery

Imagine a battery that charges faster, lasts longer, and can’t catch fire. That’s the promise of solid-state technology, and researchers have been racing to make it practical.

Energy storage is the key to our increasingly portable and electric world. We can drive more cleanly, store renewable energy, and charge our gadgets at the coffee shop, all thanks to lithium-ion batteries. It’s this liquid electrolyte, ubiquitous in our batteries, which makes all our electric vehicles, laptops, and cell phones possible.

Wondrous world-turning stuff, no doubt. However, the liquid electrolyte has several issues. It’s toxic and famously flammable, subject to dendrite growth, which can short-circuit the batteries, and not as energy dense as it could be.

All those problems go away if a solid electrolyte is used instead of liquid. But making such a thing has its problems. The solid particles—usually ceramics—are not as easily interconnected as a liquid. Hard, brittle particles with hard, brittle edges do not conjoin simply. The space between particles, known as grain boundaries, prevents the free flow of electrons from the anode to the cathode. This interface resistance hampers the ability of solid-state batteries to compete with today's lithium-ion batteries. Pennsylvania State University's solution: A cool, cost-effective process that could unlock its full potential.

And it might be closer to market than you think.

“The solid battery has a high theoretical capacity or high theoretical energy density,” said Hongtao Sun, a professor of industrial and manufacturing engineering at Penn State, and co-author of the paper “Probing cold sintering-regulated interfaces and integration of polymer-in-ceramic solid-state electrolytes,” which appeared in the journal Materials Today Energy this spring.

“But if scientists cannot address the interface resistance issue, the practical performance is even lower than the liquid battery system. So that’s the major challenge,” Sun said.

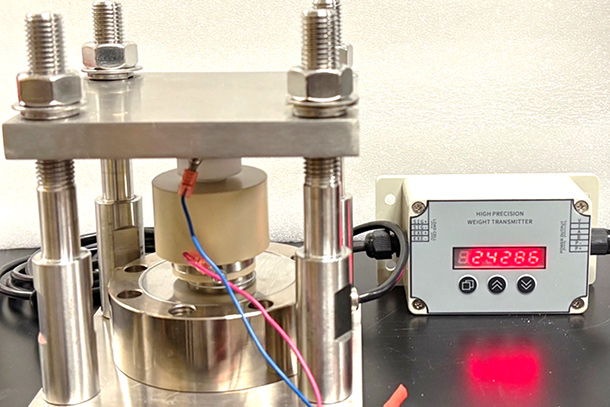

Interface resistance can be overcome through high-pressure, high-temperature sintering. However, the temperatures are so high (1,500 to 1,800 °F, roughly 80 percent of the melting point of the materials being sintered) that the process becomes prohibitively expensive. However, Sun has now developed a cold sintering method that is likely to bring solid-state batteries to vehicles and gadgets everywhere.

Like others who have attempted to create a solid-state battery, Sun utilizes a ceramic base. To that, he has added a conductive polymer, which constitutes less than 5 percent of the total material. The polymer is soft, while the ceramic is brittle. But together they become one.

“This polymer can play the role of a binder or glue that can easily integrate everything together,” Sun said.

He continued, “With it, there’s a dramatic decrease in interface resistance. Otherwise, we cannot achieve even one or two charge/discharge cycles.”

The composite is made possible thanks to a transient liquid added to the process, which evaporates when heat and pressure are applied. The polymer enables the mixing of materials to be sintered at a significantly lower temperature—as low as 300 °F—and compressed into a highly dense form.

“It’s definitely can replace current batteries using liquid electrolytes, and it has higher performance,” said Sun. “So we’re calling it the next generation rechargeable battery.”

Their lab-built battery is currently of the tiny variety—57 mm by 44 mm, to be exact—essentially a coin cell. However, the proof of concept means it can be easily adapted to almost any situation.

“It’s all about the balance between performance and cost,” Sun said. “Generally speaking, the solid battery can target many different applications, like consumer electronics, electrical vehicles, as well as large scale energy storage. So there’s no limitation for applications.”

Sun and his colleagues have applied for a provisional patent. They are also working on further improving the energy density, as well as optimizing the manufacturing process, and hope to eventually scale up to a continuous sintering process, such as a hot roller press.

“That’s the goal,” Sun said. “If we want to move forward to commercialization.”

Michael Abrams is a technology writer in Westfield, N.J.

Wondrous world-turning stuff, no doubt. However, the liquid electrolyte has several issues. It’s toxic and famously flammable, subject to dendrite growth, which can short-circuit the batteries, and not as energy dense as it could be.

All those problems go away if a solid electrolyte is used instead of liquid. But making such a thing has its problems. The solid particles—usually ceramics—are not as easily interconnected as a liquid. Hard, brittle particles with hard, brittle edges do not conjoin simply. The space between particles, known as grain boundaries, prevents the free flow of electrons from the anode to the cathode. This interface resistance hampers the ability of solid-state batteries to compete with today's lithium-ion batteries. Pennsylvania State University's solution: A cool, cost-effective process that could unlock its full potential.

And it might be closer to market than you think.

The limits of lithium-ion

“The solid battery has a high theoretical capacity or high theoretical energy density,” said Hongtao Sun, a professor of industrial and manufacturing engineering at Penn State, and co-author of the paper “Probing cold sintering-regulated interfaces and integration of polymer-in-ceramic solid-state electrolytes,” which appeared in the journal Materials Today Energy this spring.

“But if scientists cannot address the interface resistance issue, the practical performance is even lower than the liquid battery system. So that’s the major challenge,” Sun said.

Interface resistance can be overcome through high-pressure, high-temperature sintering. However, the temperatures are so high (1,500 to 1,800 °F, roughly 80 percent of the melting point of the materials being sintered) that the process becomes prohibitively expensive. However, Sun has now developed a cold sintering method that is likely to bring solid-state batteries to vehicles and gadgets everywhere.

Like others who have attempted to create a solid-state battery, Sun utilizes a ceramic base. To that, he has added a conductive polymer, which constitutes less than 5 percent of the total material. The polymer is soft, while the ceramic is brittle. But together they become one.

“This polymer can play the role of a binder or glue that can easily integrate everything together,” Sun said.

He continued, “With it, there’s a dramatic decrease in interface resistance. Otherwise, we cannot achieve even one or two charge/discharge cycles.”

The composite is made possible thanks to a transient liquid added to the process, which evaporates when heat and pressure are applied. The polymer enables the mixing of materials to be sintered at a significantly lower temperature—as low as 300 °F—and compressed into a highly dense form.

“It’s definitely can replace current batteries using liquid electrolytes, and it has higher performance,” said Sun. “So we’re calling it the next generation rechargeable battery.”

Scaling up for real-world use

Their lab-built battery is currently of the tiny variety—57 mm by 44 mm, to be exact—essentially a coin cell. However, the proof of concept means it can be easily adapted to almost any situation.

“It’s all about the balance between performance and cost,” Sun said. “Generally speaking, the solid battery can target many different applications, like consumer electronics, electrical vehicles, as well as large scale energy storage. So there’s no limitation for applications.”

Sun and his colleagues have applied for a provisional patent. They are also working on further improving the energy density, as well as optimizing the manufacturing process, and hope to eventually scale up to a continuous sintering process, such as a hot roller press.

“That’s the goal,” Sun said. “If we want to move forward to commercialization.”

Michael Abrams is a technology writer in Westfield, N.J.

.png?width=854&height=480&ext=.png)