Researcher Focus: Advanced Materials

Researcher Focus: Advanced Materials

Professor Shiren Wang, Director of the Nanomanufacturing and Nanomaterials Laboratory at Texas Tech

Researcher Focus: Advanced Materials Interview conducted by Paul Glanville

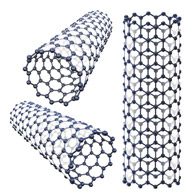

In a nutshell tell us about your research... focused on nanomaterial processing to apply nanomaterials for the energy applications.

How does your results compare with standard supercapacitors right now? Generally the supercapacitors has a high-powered density. That’s pretty good. This is an issue in the market, so we try to use the nano wire as an electrode. As a result, we found out what this kind of nanomaterial can do to significantly improve the high-powered density.

Help me imagine what kinds of technologies would use a super capacitor? The most prominent one we hope to use it in the future is the electric powered car.

What sorts of issues do you run into with the fabrication of these nanomaterials? Using nanomanufacturing techniques we assemble the nanostructures individually and then to scale.

Is that a pretty difficult process to achieve in the lab? It’s currently pretty simple.

What are some of the ways that you verify that, visually or otherwise? We use microscopes to look at the hierarchical structure. We can see that there is a one dimension in a wire, and a two dimension nanomaterial structure.

You probably have quite a few students working with you on this research. How did they come to learn about your research, and I imagine they’re very excited about it? Yes. In the beginning, they are motivated by the application, because the supercapacitor has really big potential application. Like a cell phone. Cheaper iPhones that they use I think maybe have about two and a half days of life, that’s a problem. So they are motivated by the potential application, and then they come to learn the fabrication process.

Now your research is inherently tied between the fields of mechanical engineering and electronics engineering. How do you and your students cross both disciplines? I think it’s just going to be such a hybrid. I’m calling that industrial engineering, but mostly a form of manufacturing. Our students, including myself, represent manufacturing engineering, mechanical engineering, and sometimes material engineering. For my students that want to work here on this topic I suggest they take a class in different departments, in a different area. The purpose is to try to learn specific knowledge for this kind of nanomanufacturing for energy applications.

When you were a younger researcher back in your graduate school days how did you find out about this area of research, and how did you know you were interested in energy applications? I checked the job market to see how many job openings were in this kind of field. I understood, the energy issue is pretty important. When you read the newspapers or watch TV, energy is a big challenge around the world. So I think, maybe if you work in this area you’ll get more opportunities for your career, because this is kind of an important question to everybody. We have to drive cars, so how can we reduce the oil at the point of consumption, how do you reduce the dependence and the fuel. Maybe potentially we do can develop a good solution.

What you’re saying is that looking at societal problems first. Then you see job opportunities, then you focus your research in that area. Yes. Because everybody is looking for a job, so we look at society issues. In the ASME magazine, look at the job ads, you’ll see how many opportunities go in this direction. So that’s most important motivation for us to work on.

How do you think your students can be better prepared for the advanced manufacturing industry? They need to learn some basic material processes and how to combine that knowledge in ways that targets an application.

Do you give them opportunities to be creative, working in teams? Yes. They’ve created work plans, provided ideas, and executed their projects. I provide some suggestions, to give us a better solution maybe. We work together as a team.

One of the other things that ASME focuses on in addition to energy is the global workforce. Are there ways with you and your research, have you worked across countries, or worked across other sorts of boundaries using electronic tools? Currently we have not explored this. We’re trying to collaborate with the international peers, however, we have some kind of IP issues with the University.

Do you find that your students/researchers have to become fluent in IP terms and learning intellectual property law? Yes. Before they can join a project they get training from the University and the foundation, to understand the IP property issues, and not to distribute the information without permission. We have to be careful with IP issues because it’s related to some kind of economic benefit.

What are some ways, you think, your students that are completing their programs, could be ready to be engineers in industry? They have to gain the manufacturing knowledge, learn how to find the problem, and how to solve the problem in the real world.

In your current research are you working with industry at all? We have some collaboration with the 3M Company. They bring the problem to us and say we’ll see how it can happen, how they can solve the problem. That’s directly very useful for research.

Your students are getting early exposure to industrial R&D. Yes, exactly. They understand the research is useful. It’s not just a published paper.

What are some differences for engineers to learn of academic R&D versus industry R&D? In Academia, generally people are following some very basic fundamental issues. There is a lot of false applications. For the industry, the work is driven by a specific application issue. What’s the challenge of the application in the real world? And then we try to combined the academic and the industry together, because that means, how do you say, is mostly is an application inspired researcher, so if there’s any problem with the application then we go back to the fundamental issues. And then with the fundamental understanding the issue was the solution for the application. This is what we call a useful application inspired researcher.

Tell me about how you began to get involved with ASME? What things have you initially got out of being an ASME member? The ASME is very good as a society, because I work in manufacturing and I get more experience and more networking with other peers in the industry.

Beyond laptops and electric cars and smart phones, are there other areas where these nanomaterials can go? They can also be applied to the medical industry and tissue engineering. This is a medical manufacturing.

And is your lab capable of covering all those areas? So far, not yet. We tried to collaborate with the medical center, and some experts in that field. We’ll see how we can apply our knowledge to sort of problems in the medical issues. We are looking for inspiration.

Is there anything else you’d like to say to early career engineers? Work harder for the course study, and then try to think independently and bridge the course learning with the future career opportunities. Then maybe they’re more excited for learning.

Professor Shiren Wang has published papers on The ASME Digital Collection, including the following from the 2013 ASME Congress Proceedings (IMECE2013): Fabrication of Graphene Reinforced Aluminum Composite by Semi-Solid Processing

.png?width=854&height=480&ext=.png)