Engineering a New Test Track

Engineering a New Test Track

By Thomas Stefanchik

For more than ten years now, Test Track has been one of the most popular attractions at Walt Disney World’s Epcot Center, and with good reason. The white knuckle, 65 mph lap around the Test Track course is the longest and fastest ride in all of Disney World. And with its emphasis on vehicle design, safety and testing, the attraction has always been of special interest to engineers. As good as this attraction was, however, the folks at Disney, perhaps motivated by the phenomenal success of Universal Studio’s Wizarding World of Harry Potter, felt the need to improve upon it.

Scheduled to re-open this fall (December 6, 2012), Chevrolet Design Center at Epcot will allow guests to become immersed in the world of automotive design, as they create their own custom vehicles, and then take them out for a spin.

The Chevrolet Design Center will actually be the third iteration of a GM-sponsored pavilion at Epcot. When the park opened in 1982, the attraction was entitled World of Motion. Incorporating Disney’s signature audio-animatronic figures, it featured a whimsical ride through the history of transportation, from the dawn of time to the present day (much the way “Spaceship Earth” tracks the history of communication). However, theme park competition grew ever more heated in Orlando once Universal Studios opened in 1989, and so by the mid-1990’s Disney decided to re-imagine World of Motion, as a thrill ride. And thus Test Track was born.

Estimated to cost more than $100 million, Test Track was in and of itself a wonder of engineering, one which encountered numerous road blocks on its way to opening. From 1997, its original opening date, to 1998, its actual opening, the attraction was subjected to numerous design changes, operational failures and “soft openings”.

Operational glitches aside, the technical specifications of Test Track are nothing short of remarkable:

- The ride vehicles each travel 140 miles per day, or 50,000 miles per year. That is approximately four times the average annual mileage a car is driven in the United States.

- The vehicles were designed to last for 1 million miles. That is equal to driving from the Earth to the moon more than four times.

- Making 100 million ride-system calculations per second, the vehicles’ three onboard computers have more processing power than the Space Shuttle.

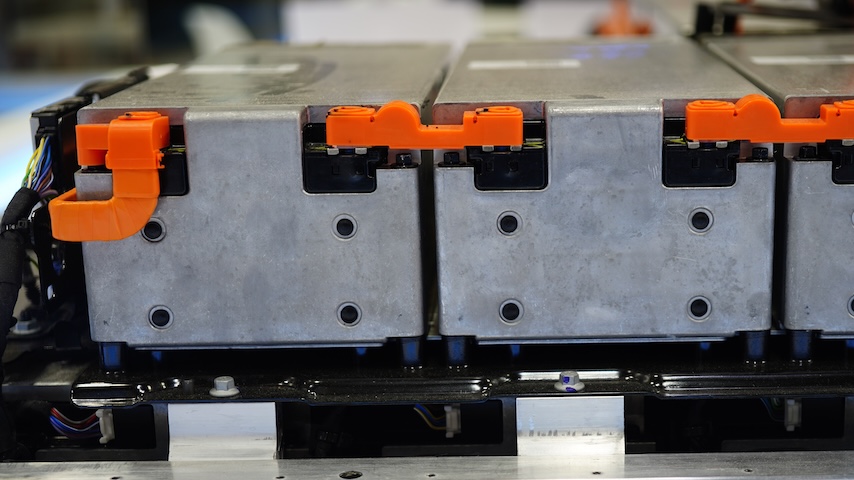

- The engine is a 250 horsepower electric motor, giving it more horsepower than a Chevy Blazer.

- The chassis is made completely of composite materials.

- Goodyear provides the tires for the Test Track vehicles. They are at 70psi (pounds per square inch) instead of the usual 35. This makes the bumps feel intentionally bumpier.

- Each vehicle is equipped with 6 braking systems, whereas today's cars have only one or two systems.

- The Heat Room in which the vehicles pass through features 192 heat lamps baking guests at a toasty 140° Fahrenheit; by comparison, the Cold Room is a moderate 40° Fahrenheit.

- The test vehicle goes through 34 turns, climbs a three-story hill and speeds around a track banked at an angle of 50°.

- It takes 8.8 seconds for the test vehicle to go from 0 to 65 mi/h.

As technically impressive and flat-out thrilling, as Test Track was, the attraction lacked one attribute: strong queuing area. The trend these days is for guests to be entertained and/or informed while enduring the inevitable, often interminable, lines for their favorite rides. (A perfect example of this is the interactive walk through Hogwarts which precedes Harry Potter and the Forbidden Journey at Universal’s Islands of Adventure.) At Test Track, guests would simply shuffle their way through a large open area filled with test track dummies and spare auto parts.

And so the attraction, as well as its queuing area, has been re-imagined once again. The new version will feature “upbeat music, engaging media, dramatic lighting and a collection of Chevrolet concept cars and model vehicles,” according to a Disney spokesperson. Guests will use interactive design and styling workstations to create custom concept vehicles, after which they will hop aboard a “SimCar” ride vehicle and put their designs to the test through the twists, turns, and bumps of the Test Track course. The actual ride itself may or may not change based on the guests’ input, considering that up to 6 passengers will each have their own designs when entering the vehicles. Disney recently (and briefly) tested this technology on Test Track by handing select guests cards to hold throughout the ride. It’s possible this technology will be incorporated into the new design stations, allowing guests to bring their concept car data onto the rides for “testing” along the way.

After the ride, a new post-show area will feature special effects and scores on how well their custom concepts did. And guests will have the opportunity to marvel at the latest Chevrolets in Test Track’s high-tech showroom, a post-ride viewing area which, although re-designed many times, has been part of the attraction since the World of Motion Days. In fact, in order to make the update happen, Disney and General Motors renewed their long-term business relationship with a new multi-year corporate alliance. And GM has been actively involved with Walt Disney Imagineering in the development of the design-centric Test Track experience.

All of which means they’ll be something for everyone, thrill-seekers, automotive fanatics, design engineers and theme park enthusiasts alike, when The Chevrolet Design Center at Epcot finally opens (December 6, 2012).