Supercritical CO₂ Enhances Oil Production Efficiency

Supercritical CO₂ Enhances Oil Production Efficiency

The University of Texas at Austin and Southwest Research Institute developed a foam-entrapped supercritical CO₂ method that boosts oil recovery and locks carbon safely underground.

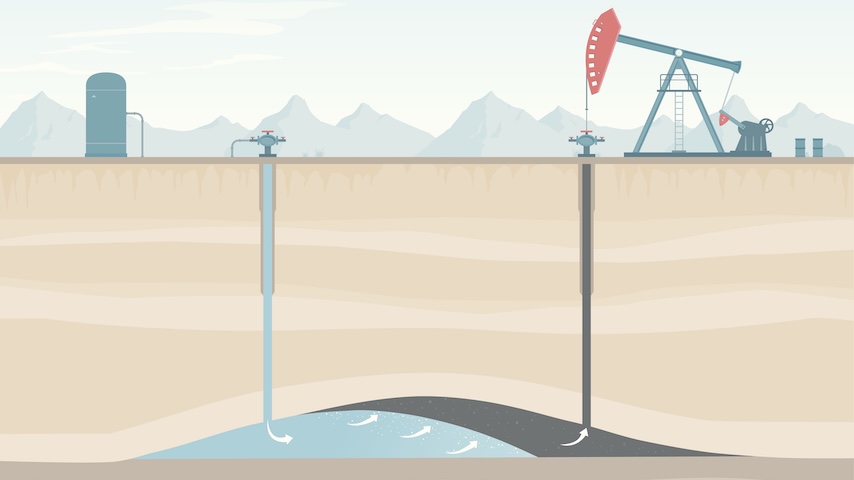

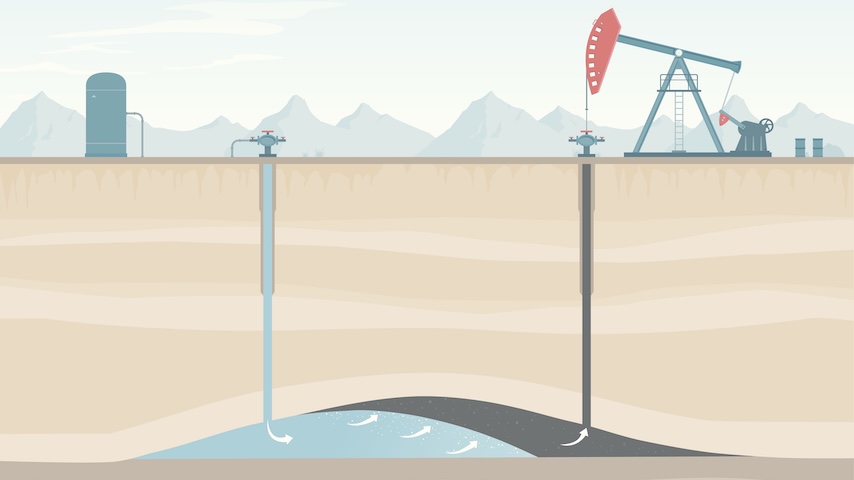

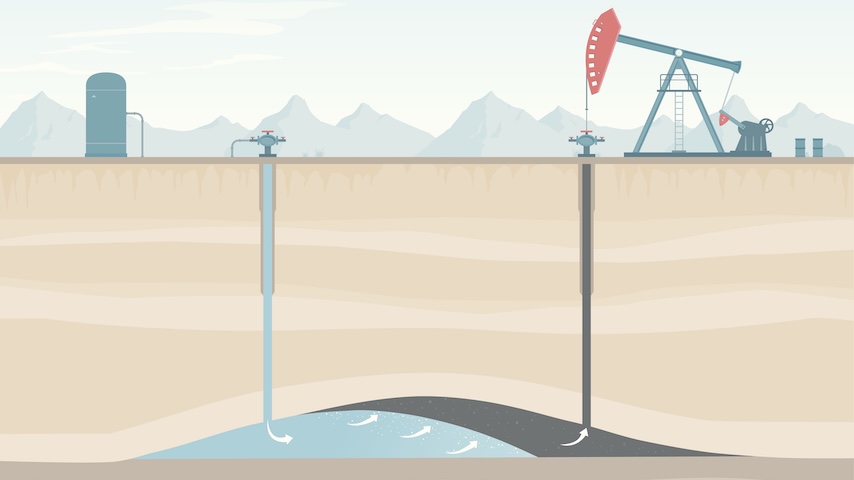

Carbon capture, utilization, and sequestration (CCUS) is a process that injects CO2 underground to enhance oil recovery (EOR) from depleted reservoirs. The CO2 has been recovered from older oil and gas operations to help extract additional oil, which will be stored within the reservoir. Although carbon storage is a standard approach for reducing atmospheric carbon, making sure the stored CO2 does not migrate back to the surface can be a challenge.

With the intention of finding a better way to ensure the stored CO2 stays in place, researchers at the University of Texas at Austin and the Southwest Research Institute (SwRI) have developed a new method for enhancing oil recovery and long-term carbon storage. This method relies on foam-entrapped supercritical carbon dioxide (sCO2) to prevent captured and stored carbon from migrating back to the surface in depleted oil and gas reservoirs.

Supercritical CO2 (sCO2) foam injection is a process that offers advantages over traditional EOR techniques, such as surfactant-alternating-gas (SAG) methods. Desirable sCO2 properties, especially low viscosity and high diffusivity, can optimize oil recovery and facilitate long-term carbon storage. These foams also exhibit a behavior known as shear thinning, which means viscosity decreases under higher shear rates, allowing them to flow more easily through high-porosity zones that have less flow through less permeable rocks, which enhances oil recovery and helps mitigate CO2 migration by restricting flow into fractured strata within the reservoir.

Due to these properties, the team decided to target foam-entrapped sCO2 as a way to extract more oil from existing wells and prevent captured CO2 from migrating upward. The researchers used traditional CO2 EOR methods to test the stability and behavior of foam-entrapped CO2 in high-temperature and high-pressure reservoir conditions. They subjected the sCO2 foams to high temperatures and pressures in a heterogeneous sand pack system that closely mimics the structure of complex reservoir environments.

“Conducted at a constant pressure of 1,200 psig and temperature of 150 °C, the experimental setup investigated the impact of varying foam flow rates from 90 ml/min to 180 ml/min and foam qualities between 65 and 97 percent,” said Angel Wileman, who also manages SwRI’s thermofluids section.

The study confirms that the viscosity of sCO2 foam peaks at a quality of 95 percent, a crucial point for enhancing sweep efficiency and structural integrity.

“Our data demonstrate the consistency of this viscosity peak under high flow rates and within a heterogeneous medium, reinforcing the potential of sCO2 foam for tailored applications in advanced oil recovery and CCUS strategies,” she continued. “These insights help optimize the operational parameters of CO2-based technologies, ensuring effective deployment in diverse geological settings.”

Results also show that increased flow rates enhance viscosity, potentially improving sweep efficiency in EOR operations, while lower temperatures correlate with greater foam stability under reduced thermal stress.

“Downflow conditions slightly elevate viscosity, likely aided by gravity, which is advantageous for vertical EOR injection strategies. These insights underscore the effectiveness of sCO2 foam in both EOR and CCUS, providing valuable data to refine foam injection techniques and optimize CO2 sequestration in varying reservoir conditions,” Wileman said.

The experimental setup also serves as a model for evaluating foam performance at pilot-project scales, enabling precise monitoring of viscosity, pressure, and temperature.

Wileman’s research shows that foams can remain stable at high pressure and temperatures. However, there are several barriers to commercializing her sCO2 process. The first is the cost of the equipment to generate foam; the second is the availability of CO2.

“If an operator were to use this equipment, it would need a ready supply of CO2,” she said.

Foam could also be generated downhole by utilizing the EOR process of alternating water and surfactant with gas. Wileman is interested in working with oil companies to develop applications for their specific wells, or to further test the sCO2 process in the field.

“I look forward to working with industry,” she said. “EOR is a hot topic, especially in the Permian Basin with its unconventional wells.”

These laboratory experiments are a crucial first step toward understanding the behavior of sCO2 foams under various conditions, before attempting field applications. By comparing different testing methods and scales, Wileman hopes to develop a comprehensive understanding of the utility of sCO2 foamsfoams, and the challenges associated with their use in the field.

Mark Crawford is a technology writer in Corrales, N.M

With the intention of finding a better way to ensure the stored CO2 stays in place, researchers at the University of Texas at Austin and the Southwest Research Institute (SwRI) have developed a new method for enhancing oil recovery and long-term carbon storage. This method relies on foam-entrapped supercritical carbon dioxide (sCO2) to prevent captured and stored carbon from migrating back to the surface in depleted oil and gas reservoirs.

Supercritical CO2

Supercritical CO2 (sCO2) foam injection is a process that offers advantages over traditional EOR techniques, such as surfactant-alternating-gas (SAG) methods. Desirable sCO2 properties, especially low viscosity and high diffusivity, can optimize oil recovery and facilitate long-term carbon storage. These foams also exhibit a behavior known as shear thinning, which means viscosity decreases under higher shear rates, allowing them to flow more easily through high-porosity zones that have less flow through less permeable rocks, which enhances oil recovery and helps mitigate CO2 migration by restricting flow into fractured strata within the reservoir.

Due to these properties, the team decided to target foam-entrapped sCO2 as a way to extract more oil from existing wells and prevent captured CO2 from migrating upward. The researchers used traditional CO2 EOR methods to test the stability and behavior of foam-entrapped CO2 in high-temperature and high-pressure reservoir conditions. They subjected the sCO2 foams to high temperatures and pressures in a heterogeneous sand pack system that closely mimics the structure of complex reservoir environments.

“Conducted at a constant pressure of 1,200 psig and temperature of 150 °C, the experimental setup investigated the impact of varying foam flow rates from 90 ml/min to 180 ml/min and foam qualities between 65 and 97 percent,” said Angel Wileman, who also manages SwRI’s thermofluids section.

The study confirms that the viscosity of sCO2 foam peaks at a quality of 95 percent, a crucial point for enhancing sweep efficiency and structural integrity.

“Our data demonstrate the consistency of this viscosity peak under high flow rates and within a heterogeneous medium, reinforcing the potential of sCO2 foam for tailored applications in advanced oil recovery and CCUS strategies,” she continued. “These insights help optimize the operational parameters of CO2-based technologies, ensuring effective deployment in diverse geological settings.”

Results also show that increased flow rates enhance viscosity, potentially improving sweep efficiency in EOR operations, while lower temperatures correlate with greater foam stability under reduced thermal stress.

“Downflow conditions slightly elevate viscosity, likely aided by gravity, which is advantageous for vertical EOR injection strategies. These insights underscore the effectiveness of sCO2 foam in both EOR and CCUS, providing valuable data to refine foam injection techniques and optimize CO2 sequestration in varying reservoir conditions,” Wileman said.

The experimental setup also serves as a model for evaluating foam performance at pilot-project scales, enabling precise monitoring of viscosity, pressure, and temperature.

Future plans

Wileman’s research shows that foams can remain stable at high pressure and temperatures. However, there are several barriers to commercializing her sCO2 process. The first is the cost of the equipment to generate foam; the second is the availability of CO2.

“If an operator were to use this equipment, it would need a ready supply of CO2,” she said.

Foam could also be generated downhole by utilizing the EOR process of alternating water and surfactant with gas. Wileman is interested in working with oil companies to develop applications for their specific wells, or to further test the sCO2 process in the field.

“I look forward to working with industry,” she said. “EOR is a hot topic, especially in the Permian Basin with its unconventional wells.”

These laboratory experiments are a crucial first step toward understanding the behavior of sCO2 foams under various conditions, before attempting field applications. By comparing different testing methods and scales, Wileman hopes to develop a comprehensive understanding of the utility of sCO2 foamsfoams, and the challenges associated with their use in the field.

Mark Crawford is a technology writer in Corrales, N.M