Stryker 3D Printing for Artificial Joints; From R&D to Production

Stryker 3D Printing for Artificial Joints; From R&D to Production

Stryker is now using metal 3D printing to manufacture artificial joints. But it took years of testing and iteration before company engineers could be certain additive manufacturing was “production ready.” In this video, ASME tells the story of that R&D journey.

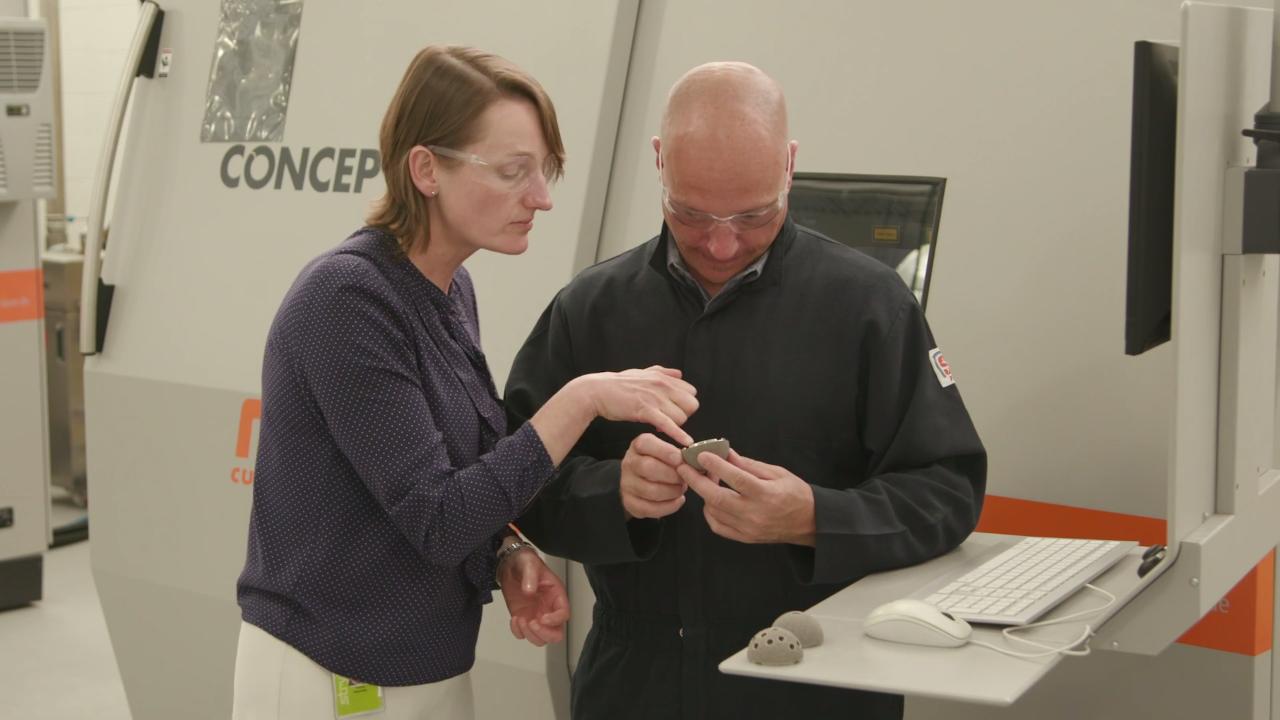

Stryker Joint Replacement is turning out components for artificial hips and knees using GE Additive’s Concept Laser printers at its new manufacturing plant in Cork, Ireland. The titanium alloy parts have surfaces with good porosity for bio-integration, an important property for adhesion in cementless artificial joints. The 3D technology also offers unprecedented design freedom.

But when the company first started exploring the merits of additive manufacturing, no one knew if the technology could meet benchmarks for quality, consistency and cost. So Stryker began a long series of tests and design iteration. That R&D journey is described in this video through interviews with Stryker’s Robert Cohen, VP for Global R&D and Chief Technology Officer, and Lewis Mullen, Senior Manager for Stryker’s Advanced Technology Group. Also featured is Naomi Murray, Director of Advanced Operations for Stryker Global Quality and Operations.

In this case study, the Stryker engineers also share lessons that may be valuable to other manufacturers who are evaluating the business and technical merits of additive manufacturing.

This video was produced by ASME’s Roger Torda.