Strength from the Deep Sea

Strength from the Deep Sea

The skeletal structure of a deep-sea sponge inspired researchers to develop a new material with remarkable compressive strength and stiffness.

Deep in the Pacific Ocean lives a species of sea sponge famous for its intricate latticelike skeleton, called Venus’s flower basket. This creature’s internal structure has inspired a new material, developed by a team of engineers at Australia’s RMIT University.

“Nature has optimized material structures over millions of years,” said Jiaming Ma, a structural engineer and post-doctoral researcher at RMIT. “This natural design enables the sponge to maintain structural integrity under extreme ocean pressures while remaining lightweight.”

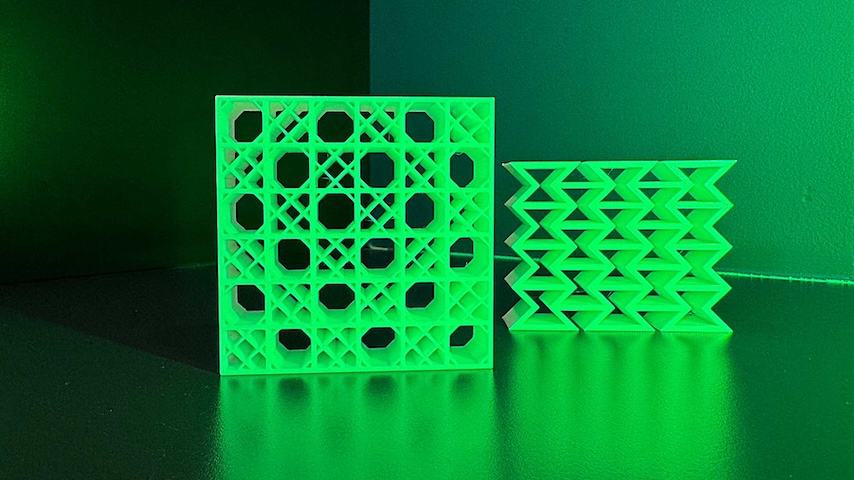

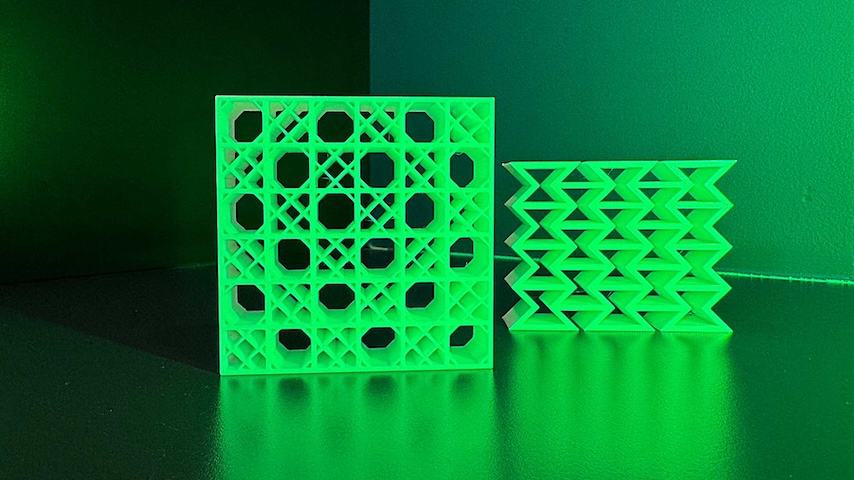

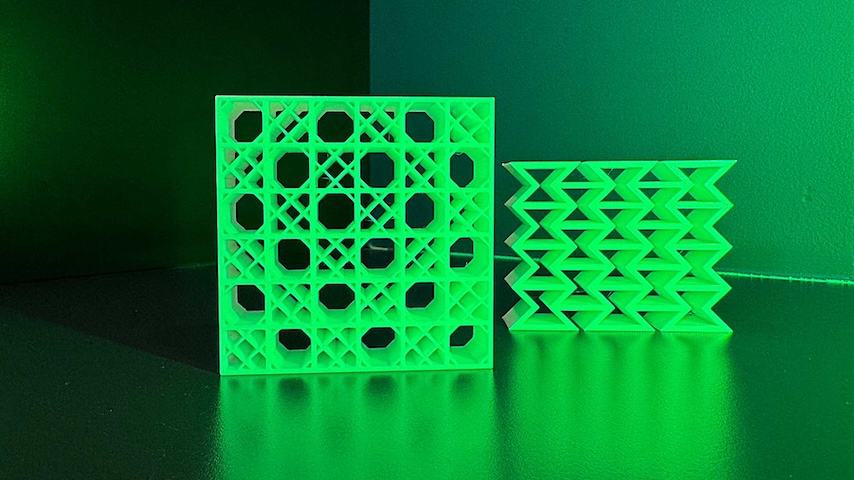

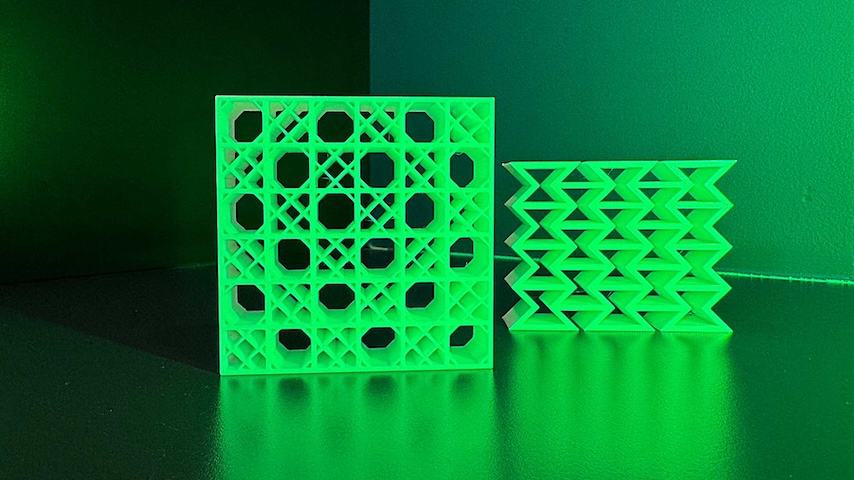

The team decided to mimic and optimize this structure to see what would happen through a series of experiments and simulations to test various concepts. The result is a double-lattice material with exceptional stiffness, superior energy absorption, and the ability to contract when compressed—otherwise known as auxetic behavior.

“The outstanding auxetic property of our lattice material was a big surprise,” Ma said, adding that these properties “make this lattice material a real game changer.”

Unique behavior

Although most materials get thinner when they are stretched and thicker when they are compressed, auxetic materials exhibit the opposite behavior. Their mechanical properties allow them to distribute impact energy more effectively, making them extremely useful for a variety of impact-resistant applications. Existing auxetic materials are also used to make heart and vascular stents that expand and contract as needed.

What can be accomplished using auxetic materials, however, is limited by their low stiffness and limited energy absorption capabilities. But the RMIT team’s nature-inspired double lattice design overcomes these limitations.

Each lattice on its own has traditional deformation behavior, but when combined as they are in the deep-sea sponge, they become self-regulating and maintain form and function, compared to other auxetic materials.

Discover the Benefits of ASME Membership

Experimental results show that with the same amount of material, the lattice is 13 times stiffer than existing auxetic materials, which are based on standard re-entrant honeycomb patterns. “Our material can also absorb 10 percent more energy while maintaining its auxetic behavior with a 60 percent greater strain range, compared to existing designs,” Ma added.

The team’s research is detailed in “Auxetic behavior and energy absorption characteristics of a lattice structure inspired by deep-sea sponge,” recently published in ScienceDirect.

Broad applications

When it comes to manufacturing, this new material can be rapidly prototyped using 3D printing methods. It could also have broad applications across multiple industries, such as improving the stiffness and adaptability of vascular stents, reducing the risk of failure inside the human body, or even enhancing the performance of protective sports gear.

“The structure’s high stiffness and porosity also make it ideal for sustainable building materials,” Ma explained. “It can help reduce steel and concrete usage, which is critical for reducing carbon footprints and addressing the rising material costs for construction.”

Also Sea Sponge-Inspired: Seeing Sponges Through a New Lens

The team has tested the design at RMIT’s Center for Innovative Structures and Materials using computer simulations and a 3D-printed sample made from thermoplastic polyurethane. Ma’s current focus is using the lattice structure to develop a more sustainable building material. The auxetic and energy-absorbing features of the new material could also help dampen vibrations during earthquakes. The researchers plan to produce steel versions of the design as well.

Further research will explore different material compositions for the diagonal beams and lattice frames to further enhance the material’s performance.

“We will also employ artificial intelligence and machine learning to make the material programmable. This way, engineers and designers can customize the mechanical performance based on what they need,” Ma said.

Mark Crawford is a technology writer in Corrales, N.M.