Inservice Inspection of Nuclear Power Plant Components

Inservice Inspection of Nuclear Power Plant Components

There are 55 locations with commercially licensed operating nuclear power plants with 93 nuclear reactors in 28 U.S. states (the Indian Point Energy Center in New York has two nuclear reactors that the U.S. Energy Information Administration counts as two separate nuclear plants). Of these nuclear plants, 36 have two or more reactors. The Palo Verde nuclear power plant in Arizona is the largest nuclear plant, and it has three reactors with a combined net summer electricity generating capacity of 3,937 megawatts (MW). The R. E. Ginna Nuclear Power Plant in New York is the smallest nuclear plant, and it has one reactor with a net summer electricity generating capacity of 508 MW.

The newest nuclear reactor to enter service, Vogtle Unit 3 with 3400 MW thermal, began commercial operation in August 2022.

Vogtle Unit 4 in Georgia is still under construction.

Besides the operating nuclear power plants in the U.S., the following countries throughout the world have operating plants:

Argentina, Armenia, Belarus, Belgium, Brazil, Bulgaria, Canada, China, Czech Republic, Finland, France, Germany, Hungary, India, Iran, Japan, Korea,(Republic), Mexico, Netherlands, Pakistan, Romania, Russian Federation, Slovakia, Slovenia, South Africa, South Korea, Spain, Sweden, Switzerland, Taiwan (China), Ukraine, United Arab Emirates, and the United Kingdom.

These plants must function in a manner that protects the public safety. The American Society of Mechanical Engineers (ASME) plays a key role in ensuring that they do.

Most U.S. nuclear power plants were built in the late 1960s and went online in the early to late 1970s. Initially, industry experts and government regulators thought the inspection practices used for fossil-fueled power plants could also be used for nuclear power plants, but they quickly discovered the need for inspection procedures specific to nuclear power plant designs. Section XI of the ASME Boiler and Pressure Vessel Code (BPVC), Rules for Inservice Inspection of Nuclear Power Plant Components, was the response to that need. It represented the joint efforts of the U.S. Atomic Energy Commission’s regulatory organization [now called the Nuclear Regulatory Commission (NRC)] and the nuclear industry.

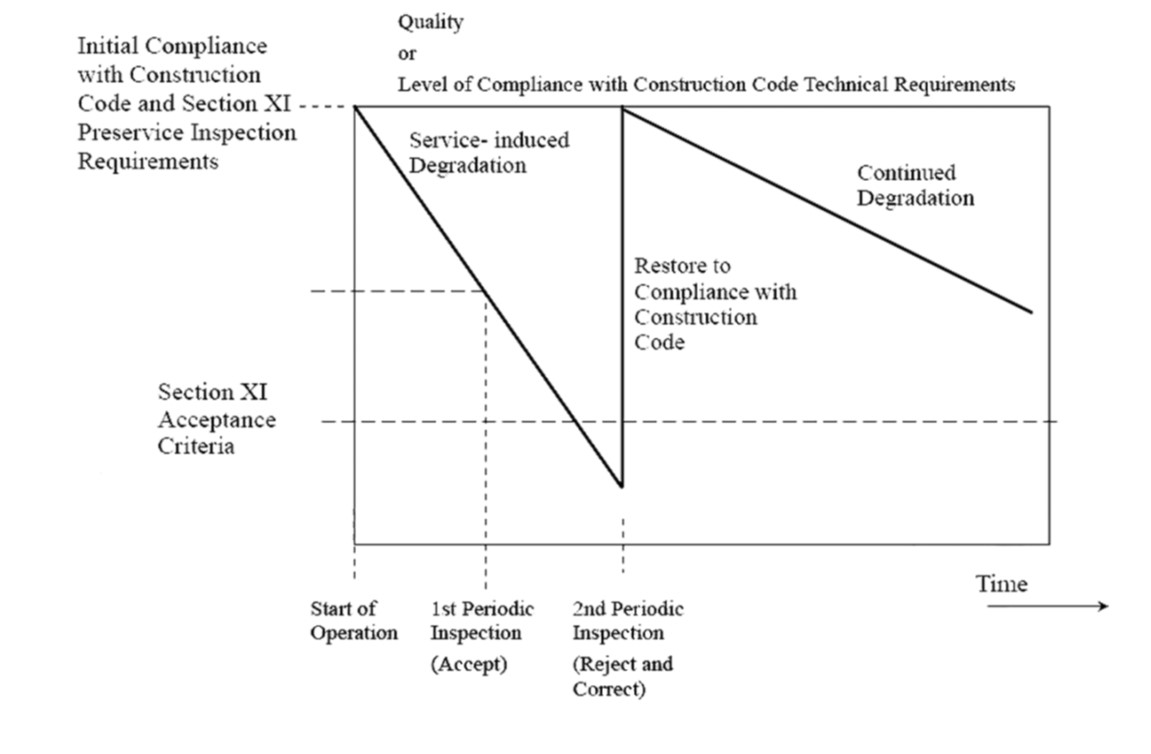

Periodic inspection of components is a fundamental part of maintaining a safely operating nuclear power plant. During construction of a plant, components are examined prior to installation to determine whether they are acceptable. Once the plant goes online, the components begin to age and degrade, and may eventually require repair or replacement. This degradation is detected by performing periodic examinations, as illustrated in the following figure:

In 1967, ASME initiated efforts to codify procedures for inspecting nuclear power plants components; those efforts culminated in a Section XI of the ASME BPVC, first published in 1970. Significant features of this Code include:

(1) the concept of designing the system to permit inspection and possible repairs

(2) the requirements of a complete examination prior to start-up to serve as a baseline for future examinations

(3) the acceptance of new inspection systems or techniques more amenable to remote application, provided such systems can be validated, and

(4) the establishment of inspection periods and levels of inspection for given components or sections of components based on the concepts of relative probability of degradation of the various portions of the systems and the significance of such degradation to the safety of the reactor system

Since the first issue of ASME BPVC Section XI, technological advancements have led to improved inspection methods. There are three methods of examination — visual, surface, and volumetric — and the type used depends on the safety significance of the component. Determining where in the plant to perform these examinations is also a key part of the inspection process. This can be done using risk evaluation techniques. Risk-informed techniques use a probabilistic risk assessment (PRA) to understand how the plant operations affect the safety of the nuclear power plant. PRA is defined as a qualitative and quantitative assessment of the risk associated with plant operation and maintenance that is measured in terms of frequency of occurrence of risk metrics, such as core damage or radioactive material release and its effects on the health of the public1. Using PRA can focus the examinations on the areas of the plant most critical to safety.

The recent resurgence of the nuclear industry has brought new challenges. For example, the development of small modular reactors has created a demand for new processes to manage and maintain them. Reliability Integrity Management (RIM), published in Division II of BPV XI, is one such process. The reliability of the nuclear plant and its systems and components is determined by the design, fabrication, inspection, surveillance, operation, and maintenance procedures used to build and operate that plant and its systems and components. In order for a nuclear plant to have a level of reliability that will satisfy both safety and economic goals, an appropriate combination of these contributors to reliability must be identified and implemented. The objective of the RIM program is to define, evaluate, and implement strategies to ensure that reliability targets for passive metallic components are defined, achieved, and maintained throughout the plant lifetime.

The NRC has incorporated ASME BPVC Section XI into the Code of Federal Regulations (CFR) Title 10, Part 50, which requires all U. S. operating nuclear power plants to develop inspection programs that meet the requirements contained therein.

The standards developed by the ASME BPV XI Committee reach well beyond the United States. They are being used throughout the world to maintain safety at operating nuclear power plants. This makes these standards unique: the examination, repair/replacement, and fracture mechanics evaluation techniques in Section XI can be applied to any reactor design.

As the nuclear industry moves forward, the ASME BPV XI Committee will continue to develop innovative ways of maintaining the safe operations of the current fleet of plants and those coming online in the future.

1ASME Boiler and Pressure Vessel Code, Section XI, Nonmandatory Appendix R, Article R-9000, Glossary.