Frugal Engineering Can Address Tomorrow’s Challenges

Frugal Engineering Can Address Tomorrow’s Challenges

As material constraints and supply chains become a larger focus for manufacturers, design cues from biology and social innovations may help engineers do more with less.

Ladakh is a plateau in the western Himalayas that averages nearly 10,000 feet in elevation. Snow falls during the bitterly cold winter, but during the brief summer when it is warm enough to grow crops, hardly any rain falls. Water from melting snow and glaciers feeds streams, but in recent years the glaciers have receded, and streams have gone dry just when they are needed for irrigation.

Around a decade ago, mechanical engineer Sonam Wangchuk noticed a block of ice that remained frozen even in warm May weather due to its permanently shaded spot under a bridge. While it would be impossible to keep a large mound of ice out of the sun, Wangchuk realized that if the ice were formed in the shape of a cone, it would have a low surface-to-volume ratio and would melt more slowly than ice and snow spread across the ground.

Because the conical shape is similar to that of traditional Buddhist shrines, Wangchuk called the artificial glaciers “ice stupas.”

Wangchuk began freezing 20-foot cones of ice, using gravity-fed water from higher elevations that would spray from the top of a standing pipe. Locally available thorny bushes acted as a branched scaffold to support the weight of ice and provide nucleation points for freezing.

The simplicity of Wangchuk’s ice stupas—no pumping was needed, only a modest amount of piping plus an arrangement of local bushes—is emblematic of a distinct “out of box” approach to designing effective engineering solutions. Rather than relying on external power and imported materials and focusing on efficiency, ice stupas are downright frugal, utilizing mostly readily available local resources and relying on thoughtful “simple” design rather than power to achieve “complex” design for engineering goals.

In recent decades, engineers have been studying examples from biology to inform industrial product designs. Biology has had millions of years to find elegant solutions under severe resource constraints, so it is prudent to examine natural systems to look for concepts to adapt for human purposes for resiliency. Familiar bio-inspired designs include surface treatments that repel water and dirt the way lotus leaves do and Velcro, which was inspired by burrs that catch on fur and clothing.

Such solutions, which often require fewer resources than alternatives, have been prized for their abilities to meet needs simply; but biology is not the only place to look for effective outcomes. Many community-based organizations have developed social innovations for providing goods and services to populations that otherwise would do without, due to societal and economic inequity. Lacking access to large sources of funding and supply chains, these social enterprises and entrepreneurs must “do more with less” and have organized themselves to be exceptionally effective.

Discover the Benefits of ASME Membership

The common thread for both bio-inspired design and social enterprises is frugality—maximizing the use of available capital resources while delivering effective outcomes. For engineers at work in the 21st century, an emphasis on frugal engineering could provide multiple advantages. Frugal engineering solutions could provide effective manufacturing product outcomes with low environmental impact but high social impact.

Because of the efficiency in management and the ability to scale these digital technologies promise, they have spread far beyond their original industrial settings. Basic human needs such as food, shelter, medical care, and education are dependent on digital means in industrialized as well as industrializing nations across the globe. However, since the majority of recent engineering advances are connected to digitization in one form or another, lack of or limited access to digital technology further exacerbates inequity. For example, most smart technologies require digital infrastructure such as internet access, which can be limited or expensive for low-resource communities. And almost all need a power supply of some sort, which means that energy inequity often maps to digital inequities.

That’s not to say that efficiency is a driver of inequity—quite the contrary. The ability to manufacture more by using less, for example by automation, is critically important in all circumstances. Resources are constrained due to the increase in population and a fast-expanding middle class of consumers, as well as the geographical limits on growth faced by megacities such as New York, Mumbai, Singapore, and Tokyo, which are bounded on at least one side by the ocean.

These constraints and their severities are similar to those faced by biological species in a living habitat. Plants must survive with the water and nutrients available in the soil and the energy provided by sunlight. Herbivores are limited by the plants they can graze, and predator populations cannot grow past the constraints set by the number of prey species. Within those resource constraints, natural systems have evolved to produce a plethora of frugal adaptations.

It would make sense, then, to expand the definition of smart technologies in the context of frugal engineering. Smartness in manufacturing in related systems should be reimagined to encompass delivering not only advanced functions but also sustainability and resilience, all while using fewer raw materials and other resources. In this conception, what must be embedded in industrial design goes beyond sensors and wireless connectivity to the lessons learned from biology.

Some additional examples of frugal engineering solutions may be useful.

Desert weather conditions present an extreme environment for plants and animals due to highly fluctuating temperatures and scarcity of resources necessary for survival and growth. In these conditions, plants need alternative strategies not only for capturing water but also to minimize the loss of captured water via evaporation.

In coastal desert regions, such as the Atacama Desert in Chile and Peru, the Namib Desert in southwestern Africa, and along the Baja Peninsula in Mexico, water is available via fogs produced by moist ocean air flowing over the land. Cacti native to the deserts of North and South America have evolved thorns that aid in capturing moisture from fog. The thorns feature hierarchical surface structures that increase surface area for collecting condensation coupled with grooved channels along the length, culminating in hairy trichomes at the base. The spines are oriented in multiple directions and the pointy tips initiate the condensation from the fog. Once a critical mass of the droplet is achieved on the surface of these tips, the axial grooves carry the droplet toward the base where it is captured via the trichomes. Similarly, certain species of desert beetles also rely on surface structures on their backs as well as their body positioning to condense and harvest water from the fog through “fog basking” behavior.

Some key design attributes of these natural systems are the sizes and shapes of structures, the hierarchy of scales and branched architectures, and the distribution of roles among connected structures. A frugal engineering solution has been developed that uses the inspiration of these natural water harvesting structures for human purposes.

In the Atacama Desert, for instance, local people have erected branched mesh structured nets over the hills to capture condensed water from the fog and collect it through a system of pipes. Depending on the site, this water can be used for either agricultural use or human consumption. This innovation targets the principle of water condensation by utilizing two important aspects of the frugal engineering framework: simplicity, and scalability for effectiveness.

A modern version of the fog net, the CloudFisher developed by the Moroccan non-governmental organization Dar Si Hmad and the German foundation WasserStiftung, can collect as much as 22 liters per square meter of netting a day. According to WasserStiftung, 31 CloudFishers built in the Anti-Atlas Mountains collect an average of more than 37,000 liters of water per day, supplying drinking water to 16 villages.

The simplicity of a fine and connected net design combined with the ability to erect scalable and multiple nets means that the usage is affordable and accessible to the local communities and does not rely on complex designs or failure-prone mechanisms of pumps and cross-mountain piping to target high efficiency of water delivery from remote sources.

Get Involved with Engineering for Change

Another natural system that can serve as inspiration for frugal engineering design is plant and animal skin. Skins of almost all biological species serve multiple functions as they represent an organism’s interface with the environment and first line of defense against environmental disturbances. One important function of skin is thermal management.

Human skin, for instance, contains layers of microscale structures, including millions of distributed pores, hair follicles, and sweat glands, as well as thermoreceptors and nerves to enable sensing and signaling functions. Thermoreceptors and neural signaling control the contraction and expansion of blood vessels to manage heat exchange through the skin layers with the environment. Sweat glands and pores are responsible for producing sweat under hot environmental conditions when the body temperature rises. The latent heat of evaporation of the sweat is widely reported to be 580 cal/g and excess body heat is utilized in the evaporation process.

Between the flow of blood and the production of perspiration, the heat energy balance is maintained between the external environment and the body. The frugal engineering approach would examine the success of this system for cooling the human body and adapting it for providing refrigeration without electricity.

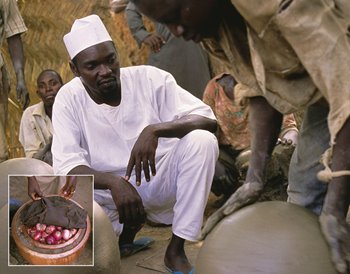

In arid and semi-arid regions of Africa where there is no reliable access to electricity, storing perishable food items is a significant challenge, especially in extremely hot weather conditions. Without proper storage methods, perishable food items such as fruits and vegetables deteriorate quickly rendering them unsuitable for consumption.

Nigerian innovator Mohammed Bah Abba created a refrigeration solution based on evaporative cooling. The pot-in-pot or zeer is a set of nested clay pots with wet sand filling the gap between them. The inner pot is usually glazed to keep the interior dry and hold fresh produce. As the water from the sand evaporates from the skin of the outer pot, which is porous, it creates a cooling effect. Fresh vegetables can be stored for up to 20 days in a zeer, as opposed to a few hours or days if left exposed to a hot environment.

One of the most attractive aspects of this system is the ability to tap into local expertise. Potters can manufacture clay plots using locally available clay, thus creating a thriving ecosystem and jobs in the community for social good. The use of locally sourced material and community involvement are two critical frugal engineering principles utilized by the pot-in-pot solution in addition to the simplicity of design and sustainability impact. And compared to the hundreds of dollars it costs to buy an electricity-powered refrigerator, a zeer can be manufactured for around one dollar per pair of pots.

Finally—and this may be the biggest break from the conventional engineering framework—the goal should be maximum effectiveness of the innovation as opposed to maximum efficiency.

The engineering methodology for developing a frugal solution has the same stages as conventional engineering: Identification of needs, followed by concept, prototyping, testing, and launch. But to find not just an optimal solution but a frugal one, much more emphasis must be placed on identifying both the environmental circumstances and available resources as well as the needs of and critical inequities for survival within the community.

The engineering methodology for developing a frugal solution has the same stages as conventional engineering: Identification of needs, followed by concept, prototyping, testing, and launch. But to find not just an optimal solution but a frugal one, much more emphasis must be placed on identifying both the environmental circumstances and available resources as well as the needs of and critical inequities for survival within the community.

On the one hand, it is important to know the exact boundary conditions that frame the frugal solution, and on the other hand, detailed information about the problem, inequity, or market pull will describe most of the product or service constructing elements and its process of operation. This is necessary for identifying the key functional product requirements at the concept design stage to create a frugally engineered “smart” product solution as a part of socially-conscious “smart” manufacturing.

The additional severe and higher resource constraints from inequity in basic human needs further lower the degrees of freedom available for designing an equitable solution and forming the correlation between the social and manufacturing boundary conditions. This is where bio-inspired design approaches enable frugal means to achieve multifunctionality, resilience, and sustainability desired for effectiveness.

ASME Offers Courses to Grow Your Skillset

It may be tempting to dismiss the frugal engineering approach as an academic exercise or something useful only in truly impoverished circumstances. But small- and mid-size enterprises (SMEs) in modern industries often face acute constraints as well. While the boundary conditions for survival are not the same as communities dealing with water or food shortages, a frugal engineering approach could provide unique solutions to help these SMEs thrive in an ultra-competitive and global market with little room to maneuver.

As the world is experiencing various changes—technological, social, economic, and climate, as well as the disruptions caused by the recent pandemic—there is an opening for alternatives to the resource-intensive model of Industry 4.0. Embedding innovations with lessons derived from both bio-based solutions and community experience and expertise can produce effective outcomes that have minimal environmental impact and maximum social impact.

Ajay P. Malshe is R. Eugene and Susie E. Goodson Distinguished Professor of Mechanical Engineering at Purdue University in West Lafayette, Ind. Salil Bapat is a research scientist at Purdue’s School of Mechanical Engineering. Lukas Fischer is a research scientist at Leibniz University Hannover and a project engineer for Mittelstand-Digital in Hannover, Germany.

This article is adapted from “Understanding Frugal Engineering for Equity: Exploring Convergence of Biological Designs and Social Innovations,” Journal of Manufacturing Science and Engineering, May 2023.

Around a decade ago, mechanical engineer Sonam Wangchuk noticed a block of ice that remained frozen even in warm May weather due to its permanently shaded spot under a bridge. While it would be impossible to keep a large mound of ice out of the sun, Wangchuk realized that if the ice were formed in the shape of a cone, it would have a low surface-to-volume ratio and would melt more slowly than ice and snow spread across the ground.

Because the conical shape is similar to that of traditional Buddhist shrines, Wangchuk called the artificial glaciers “ice stupas.”

Wangchuk began freezing 20-foot cones of ice, using gravity-fed water from higher elevations that would spray from the top of a standing pipe. Locally available thorny bushes acted as a branched scaffold to support the weight of ice and provide nucleation points for freezing.

The simplicity of Wangchuk’s ice stupas—no pumping was needed, only a modest amount of piping plus an arrangement of local bushes—is emblematic of a distinct “out of box” approach to designing effective engineering solutions. Rather than relying on external power and imported materials and focusing on efficiency, ice stupas are downright frugal, utilizing mostly readily available local resources and relying on thoughtful “simple” design rather than power to achieve “complex” design for engineering goals.

In recent decades, engineers have been studying examples from biology to inform industrial product designs. Biology has had millions of years to find elegant solutions under severe resource constraints, so it is prudent to examine natural systems to look for concepts to adapt for human purposes for resiliency. Familiar bio-inspired designs include surface treatments that repel water and dirt the way lotus leaves do and Velcro, which was inspired by burrs that catch on fur and clothing.

Such solutions, which often require fewer resources than alternatives, have been prized for their abilities to meet needs simply; but biology is not the only place to look for effective outcomes. Many community-based organizations have developed social innovations for providing goods and services to populations that otherwise would do without, due to societal and economic inequity. Lacking access to large sources of funding and supply chains, these social enterprises and entrepreneurs must “do more with less” and have organized themselves to be exceptionally effective.

Discover the Benefits of ASME Membership

The common thread for both bio-inspired design and social enterprises is frugality—maximizing the use of available capital resources while delivering effective outcomes. For engineers at work in the 21st century, an emphasis on frugal engineering could provide multiple advantages. Frugal engineering solutions could provide effective manufacturing product outcomes with low environmental impact but high social impact.

Effective Solutions

In many discussions of the future of manufacturing, the key driver is “smart” technology: The interweaving of physical systems with digital enhancements such as sensors, wireless communication, and access to cloud-based computing. Manufacturers call this melding of physical and digital systems “Industry 4.0,” and it is manifested in such technologies as robots, digital twins, autonomous cargo vehicles, Big Data, Internet-of-Things-enabled products, and digital connectivity in supply chains, transportation, and delivery.Because of the efficiency in management and the ability to scale these digital technologies promise, they have spread far beyond their original industrial settings. Basic human needs such as food, shelter, medical care, and education are dependent on digital means in industrialized as well as industrializing nations across the globe. However, since the majority of recent engineering advances are connected to digitization in one form or another, lack of or limited access to digital technology further exacerbates inequity. For example, most smart technologies require digital infrastructure such as internet access, which can be limited or expensive for low-resource communities. And almost all need a power supply of some sort, which means that energy inequity often maps to digital inequities.

That’s not to say that efficiency is a driver of inequity—quite the contrary. The ability to manufacture more by using less, for example by automation, is critically important in all circumstances. Resources are constrained due to the increase in population and a fast-expanding middle class of consumers, as well as the geographical limits on growth faced by megacities such as New York, Mumbai, Singapore, and Tokyo, which are bounded on at least one side by the ocean.

These constraints and their severities are similar to those faced by biological species in a living habitat. Plants must survive with the water and nutrients available in the soil and the energy provided by sunlight. Herbivores are limited by the plants they can graze, and predator populations cannot grow past the constraints set by the number of prey species. Within those resource constraints, natural systems have evolved to produce a plethora of frugal adaptations.

It would make sense, then, to expand the definition of smart technologies in the context of frugal engineering. Smartness in manufacturing in related systems should be reimagined to encompass delivering not only advanced functions but also sustainability and resilience, all while using fewer raw materials and other resources. In this conception, what must be embedded in industrial design goes beyond sensors and wireless connectivity to the lessons learned from biology.

Some additional examples of frugal engineering solutions may be useful.

Desert weather conditions present an extreme environment for plants and animals due to highly fluctuating temperatures and scarcity of resources necessary for survival and growth. In these conditions, plants need alternative strategies not only for capturing water but also to minimize the loss of captured water via evaporation.

In coastal desert regions, such as the Atacama Desert in Chile and Peru, the Namib Desert in southwestern Africa, and along the Baja Peninsula in Mexico, water is available via fogs produced by moist ocean air flowing over the land. Cacti native to the deserts of North and South America have evolved thorns that aid in capturing moisture from fog. The thorns feature hierarchical surface structures that increase surface area for collecting condensation coupled with grooved channels along the length, culminating in hairy trichomes at the base. The spines are oriented in multiple directions and the pointy tips initiate the condensation from the fog. Once a critical mass of the droplet is achieved on the surface of these tips, the axial grooves carry the droplet toward the base where it is captured via the trichomes. Similarly, certain species of desert beetles also rely on surface structures on their backs as well as their body positioning to condense and harvest water from the fog through “fog basking” behavior.

Some key design attributes of these natural systems are the sizes and shapes of structures, the hierarchy of scales and branched architectures, and the distribution of roles among connected structures. A frugal engineering solution has been developed that uses the inspiration of these natural water harvesting structures for human purposes.

In the Atacama Desert, for instance, local people have erected branched mesh structured nets over the hills to capture condensed water from the fog and collect it through a system of pipes. Depending on the site, this water can be used for either agricultural use or human consumption. This innovation targets the principle of water condensation by utilizing two important aspects of the frugal engineering framework: simplicity, and scalability for effectiveness.

A modern version of the fog net, the CloudFisher developed by the Moroccan non-governmental organization Dar Si Hmad and the German foundation WasserStiftung, can collect as much as 22 liters per square meter of netting a day. According to WasserStiftung, 31 CloudFishers built in the Anti-Atlas Mountains collect an average of more than 37,000 liters of water per day, supplying drinking water to 16 villages.

The simplicity of a fine and connected net design combined with the ability to erect scalable and multiple nets means that the usage is affordable and accessible to the local communities and does not rely on complex designs or failure-prone mechanisms of pumps and cross-mountain piping to target high efficiency of water delivery from remote sources.

Get Involved with Engineering for Change

Another natural system that can serve as inspiration for frugal engineering design is plant and animal skin. Skins of almost all biological species serve multiple functions as they represent an organism’s interface with the environment and first line of defense against environmental disturbances. One important function of skin is thermal management.

Human skin, for instance, contains layers of microscale structures, including millions of distributed pores, hair follicles, and sweat glands, as well as thermoreceptors and nerves to enable sensing and signaling functions. Thermoreceptors and neural signaling control the contraction and expansion of blood vessels to manage heat exchange through the skin layers with the environment. Sweat glands and pores are responsible for producing sweat under hot environmental conditions when the body temperature rises. The latent heat of evaporation of the sweat is widely reported to be 580 cal/g and excess body heat is utilized in the evaporation process.

Between the flow of blood and the production of perspiration, the heat energy balance is maintained between the external environment and the body. The frugal engineering approach would examine the success of this system for cooling the human body and adapting it for providing refrigeration without electricity.

In arid and semi-arid regions of Africa where there is no reliable access to electricity, storing perishable food items is a significant challenge, especially in extremely hot weather conditions. Without proper storage methods, perishable food items such as fruits and vegetables deteriorate quickly rendering them unsuitable for consumption.

Nigerian innovator Mohammed Bah Abba created a refrigeration solution based on evaporative cooling. The pot-in-pot or zeer is a set of nested clay pots with wet sand filling the gap between them. The inner pot is usually glazed to keep the interior dry and hold fresh produce. As the water from the sand evaporates from the skin of the outer pot, which is porous, it creates a cooling effect. Fresh vegetables can be stored for up to 20 days in a zeer, as opposed to a few hours or days if left exposed to a hot environment.

One of the most attractive aspects of this system is the ability to tap into local expertise. Potters can manufacture clay plots using locally available clay, thus creating a thriving ecosystem and jobs in the community for social good. The use of locally sourced material and community involvement are two critical frugal engineering principles utilized by the pot-in-pot solution in addition to the simplicity of design and sustainability impact. And compared to the hundreds of dollars it costs to buy an electricity-powered refrigerator, a zeer can be manufactured for around one dollar per pair of pots.

A New Approach

Those examples point to some common attributes in the frugal approach to engineering. To ensure ease of implementation, the science and engineering behind the solution should be as simple as possible. The solution also should rely on locally accessible materials and expertise to help ensure sustainability. The manufacturing should be assembly-driven and drawn from off-the-shelf components. Innovators should promote nonproprietary and open-source technology to reduce the barriers to dissemination. The development process should seek out participation from citizens in the community experiencing inequity.Finally—and this may be the biggest break from the conventional engineering framework—the goal should be maximum effectiveness of the innovation as opposed to maximum efficiency.

Explore Engineering Research

R&D Pulse provides members with reporting on cutting-edge findings from ASME journals.

On the one hand, it is important to know the exact boundary conditions that frame the frugal solution, and on the other hand, detailed information about the problem, inequity, or market pull will describe most of the product or service constructing elements and its process of operation. This is necessary for identifying the key functional product requirements at the concept design stage to create a frugally engineered “smart” product solution as a part of socially-conscious “smart” manufacturing.

The additional severe and higher resource constraints from inequity in basic human needs further lower the degrees of freedom available for designing an equitable solution and forming the correlation between the social and manufacturing boundary conditions. This is where bio-inspired design approaches enable frugal means to achieve multifunctionality, resilience, and sustainability desired for effectiveness.

ASME Offers Courses to Grow Your Skillset

It may be tempting to dismiss the frugal engineering approach as an academic exercise or something useful only in truly impoverished circumstances. But small- and mid-size enterprises (SMEs) in modern industries often face acute constraints as well. While the boundary conditions for survival are not the same as communities dealing with water or food shortages, a frugal engineering approach could provide unique solutions to help these SMEs thrive in an ultra-competitive and global market with little room to maneuver.

As the world is experiencing various changes—technological, social, economic, and climate, as well as the disruptions caused by the recent pandemic—there is an opening for alternatives to the resource-intensive model of Industry 4.0. Embedding innovations with lessons derived from both bio-based solutions and community experience and expertise can produce effective outcomes that have minimal environmental impact and maximum social impact.

Ajay P. Malshe is R. Eugene and Susie E. Goodson Distinguished Professor of Mechanical Engineering at Purdue University in West Lafayette, Ind. Salil Bapat is a research scientist at Purdue’s School of Mechanical Engineering. Lukas Fischer is a research scientist at Leibniz University Hannover and a project engineer for Mittelstand-Digital in Hannover, Germany.

This article is adapted from “Understanding Frugal Engineering for Equity: Exploring Convergence of Biological Designs and Social Innovations,” Journal of Manufacturing Science and Engineering, May 2023.

.png?width=854&height=480&ext=.png)