Flexible Finger Points to New Possibilities for Semiconducting Materials

Flexible Finger Points to New Possibilities for Semiconducting Materials

A team of researchers at the University of Melbourne and RMIT University have developed the next generation of wearables in the form of a flexible finger with enormous potential for sensing.

Wearable technologies that can monitor vital signs and perform other unique and powerful functions attract the attention of the healthcare industry, technology manufacturers, and others. Now, a team of researchers at the University of Melbourne and RMIT University have come together to develop the next generation of wearables in the form of a flexible finger with enormous potential for sensing.

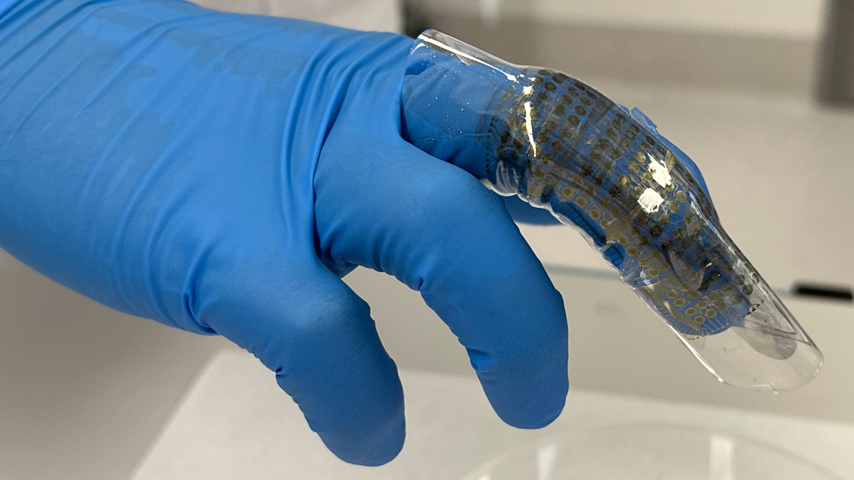

Nanomaterials layer the device, which looks like a clear casing meant to fit over the human finger. It is specially designed to perform multiple tasks including writing, erasing, and editing, and stores the memory of those tasks within a space that could fit 20 times within the width of a human hair.

Become a Member: How to Join ASME

“The goal is to continue to make things that are smaller and smarter,” said Dr. Ali Zavabeti, lecturer at the University of Melbourne, adjunct principal research fellow at RMIT, and lead corresponding author. “This memory effect is the key focus in neural networks.”

One of the difficulties of developing nanocomponents is that many metallic elements are not air-stable, making them very challenging and expensive to work with. The main material comes from the rust of a low-temperature liquid metal called bismuth.

The team—led by RMIT doctoral candidate Xiangyang Guo, under the supervision of Zavabeti and Professor Yongxiang Li (RMIT)—has conducted bismuth studies that show it is safe for humans and would cause less irritation than other popular materials. When layered using the team’s technique, the metal acts as a semiconductor, generating its power through natural forces. It can achieve a high voltage output of about 3 volts.

“The technology is ideal for continued health monitoring,” said Zavabeti. “It generates its own power, meaning that it can transfer mechanical movements like strain, stress, pressure, all of those forces, into potential energy and then that potential can store memory.”

In a liquid state, bismuth can be applied to many different surfaces like glass or film. This is one advantage the other is that this liquid state makes the applications very flexible, ultra-thin, and ideal for wearables of all varieties. It is also perfect for printing. Giving producers the ability to mass produce offerings.

More for you: Quiz: Wearable Technology

As far as how well they will hold up, the material creates less friction than silicone, which means there is less wear and tear over time. After running several cycles of open-air experiments for a month, the flexible devices demonstrated high stability, making them ideal for state-of-the-art devices.

Recognizing their importance in the future of wearable and portable technology, the team began working with and developing multifunctional nanoelectronic oxide components like bismuth back in 2017. The team had another breakthrough with the release of its paper on a gas-sensing oxide skin that can detect and alert to toxic particles in the air.

“These oxides are very, very valuable in multiple aspects,” Zavabeti said. “We are still working on how to integrate them with existing sensors and consumer products. It's a growing area of science, and it's accelerating very fast.”

One area where Zavabeti sees potential integration is with foldable electronics. As more companies like Samsung and Google release folding phones, it is likely that something like this bismuth film would be attractive to them. He also sees the technology being useful in areas where security is extra important, like encoding bank notes or authenticating art and other high-value items.

Through multiple sources, Australian Research Council and the Dyason Fellowship Program at the University of Melbourne funds the work. For now, the team will continue to develop these materials and hopes to gain additional funding to support manufacturing them on a larger scale.

Cassie Kelly is a science and technology writer in Columbus, Ohio.

Nanomaterials layer the device, which looks like a clear casing meant to fit over the human finger. It is specially designed to perform multiple tasks including writing, erasing, and editing, and stores the memory of those tasks within a space that could fit 20 times within the width of a human hair.

Become a Member: How to Join ASME

“The goal is to continue to make things that are smaller and smarter,” said Dr. Ali Zavabeti, lecturer at the University of Melbourne, adjunct principal research fellow at RMIT, and lead corresponding author. “This memory effect is the key focus in neural networks.”

Ideal for healthcare

One of the difficulties of developing nanocomponents is that many metallic elements are not air-stable, making them very challenging and expensive to work with. The main material comes from the rust of a low-temperature liquid metal called bismuth.

The team—led by RMIT doctoral candidate Xiangyang Guo, under the supervision of Zavabeti and Professor Yongxiang Li (RMIT)—has conducted bismuth studies that show it is safe for humans and would cause less irritation than other popular materials. When layered using the team’s technique, the metal acts as a semiconductor, generating its power through natural forces. It can achieve a high voltage output of about 3 volts.

“The technology is ideal for continued health monitoring,” said Zavabeti. “It generates its own power, meaning that it can transfer mechanical movements like strain, stress, pressure, all of those forces, into potential energy and then that potential can store memory.”

In a liquid state, bismuth can be applied to many different surfaces like glass or film. This is one advantage the other is that this liquid state makes the applications very flexible, ultra-thin, and ideal for wearables of all varieties. It is also perfect for printing. Giving producers the ability to mass produce offerings.

More for you: Quiz: Wearable Technology

As far as how well they will hold up, the material creates less friction than silicone, which means there is less wear and tear over time. After running several cycles of open-air experiments for a month, the flexible devices demonstrated high stability, making them ideal for state-of-the-art devices.

Potential for more

Recognizing their importance in the future of wearable and portable technology, the team began working with and developing multifunctional nanoelectronic oxide components like bismuth back in 2017. The team had another breakthrough with the release of its paper on a gas-sensing oxide skin that can detect and alert to toxic particles in the air.

“These oxides are very, very valuable in multiple aspects,” Zavabeti said. “We are still working on how to integrate them with existing sensors and consumer products. It's a growing area of science, and it's accelerating very fast.”

One area where Zavabeti sees potential integration is with foldable electronics. As more companies like Samsung and Google release folding phones, it is likely that something like this bismuth film would be attractive to them. He also sees the technology being useful in areas where security is extra important, like encoding bank notes or authenticating art and other high-value items.

Through multiple sources, Australian Research Council and the Dyason Fellowship Program at the University of Melbourne funds the work. For now, the team will continue to develop these materials and hopes to gain additional funding to support manufacturing them on a larger scale.

Cassie Kelly is a science and technology writer in Columbus, Ohio.