This Algorithm Generates Assembly Instructions

This Algorithm Generates Assembly Instructions

Researchers show that the algorithm is accurate and can be generalized to a range of complex assembles.

For all the talk about a robotic future, humans are still a big part of the manufacturing process. Assembly is one example. Robots can build the product, but engineers still need to draft the assembly plans that robots follow.

Engineers are needed because the 3D shapes that make up a part are inherently complex and assembling them into a complete product even more so. Parts have a limited range of motion, which only add to the complexity.

As such, assembly planning has resisted the automation that has long been part of the manufacturing world. While attempts have been made and algorithms do exist, they are “less than spectacular,” according to Yunsheng Tian, a Ph.D. student at the Computer Science and Artificial Intelligence Laboratory (CSAIL) at the Massachusetts Institute of Technology. He is lead author of the paper “Assemble Them All: Physics-Based Planning for Generalizable Assembly by Disassembly,” presented at SIGGRAPH Asia 2022.

Become a Member: How to Join ASME

Automating assembly instructions would slash costs. It would also allow manufacturers to quickly swap out assembly lines so they could build various products on one line rather than devoting a whole line to one product.

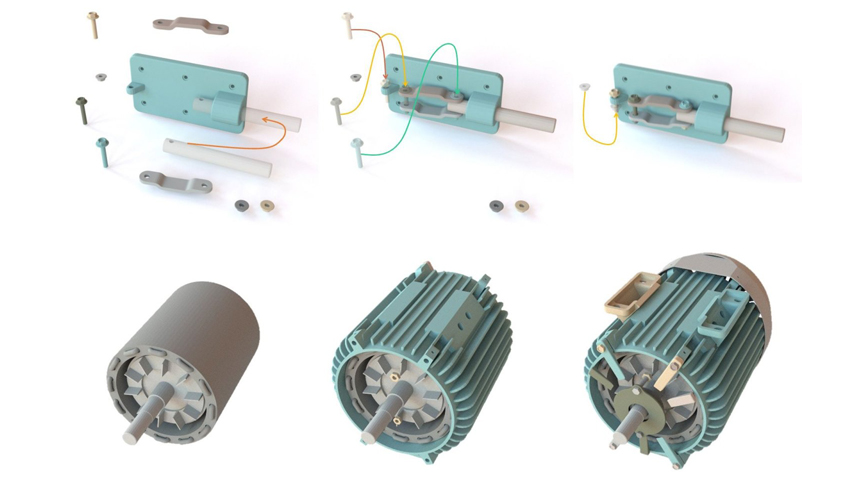

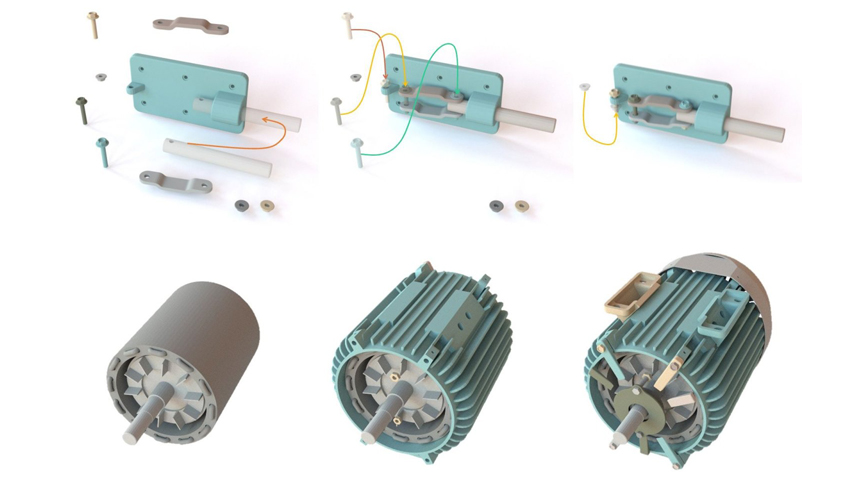

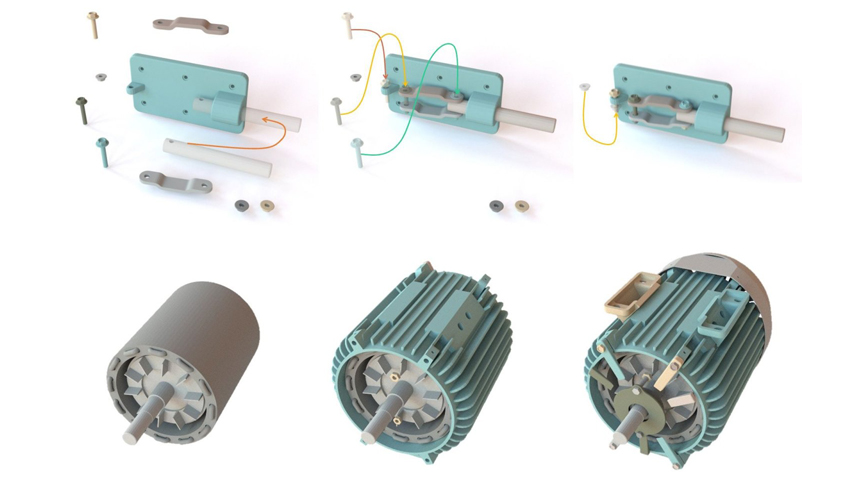

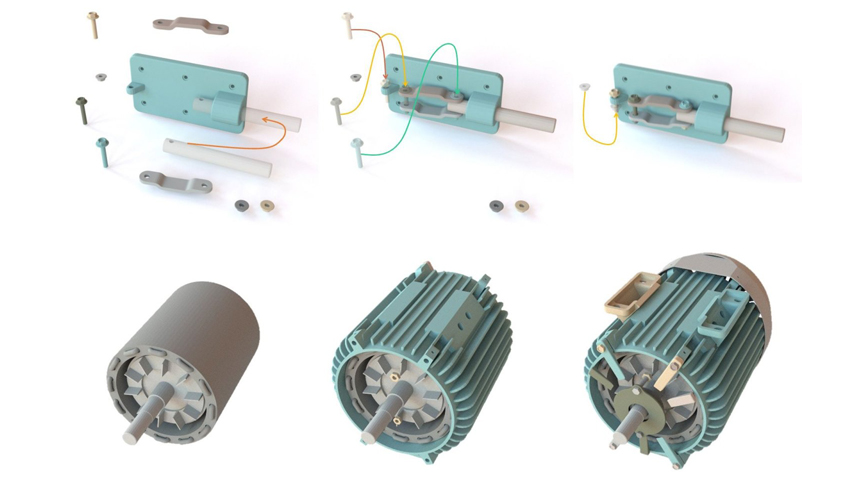

In a big step toward automating assembly planning, researchers have developed an algorithm that can automatically generate assembly plans for all types of products. The algorithm determines the order for multipart assembly, then searches for a motion path for each step to create an overall assembly plan. It can be generalized to a wide range of complex real-world assemblies, said Tian.

Researchers from Autodesk Research, CSAIL, and Texas A&M University collaborated on developing the algorithm as a way to automatically, accurately, and efficiently assemble products that cover a range of complex assemblies. It determines the order for multipart assembly, and searches for a realistic motion for each step, according to the researchers.

Using Section IX with other Construction Codes? We have a course on that.

The algorithm will help engineers as they work to find the best way to assembly a part, said Karl Willis, a senior research manager at Autodesk Research, in a statement. In the future it could automatically generate assembly instructions. It solves 80-part assemblies within several minutes, so multiple parts could be made on one assembly line that is quickly swapped out..

The method leverages the “assembly-by-disassembly principle” and physics-based simulation to explore a reduced search space, according to Tian. It solves 80-part assemblies within several minutes, and generalizes to rotational assemblies.

To test their algorithm, the researchers compiled data on thousands of industrial assemblies that required a range of motions, Tian said. Using physics-based simulation, the algorithm applies different forces to, for example, a screw that needs to be affixed to a rod. In the disassembly stage, the algorithm finds the screw’s motions that will best fit it to the rod. It then reverses the disassembly path to get an assembly solution from individual parts, he added.

Listen to Our Podcast: Six Sigma and Mechanical Engineers

The team has yet to determine how much automating assemblies could help a manufacturer’s bottom line, but they believe the number could be large. As an example, IKEA furniture has step-by-step instructions, manually authored by people. With this algorithm, it may be possible to automate those instructions.

The algorithm was tested only on rigid objects and performed well. Future work will deal with soft, deformable assemblies. The team next may explore devising a robotic setup to assemble items with the goal of making an assembly line that could assemble a part without humans.

Jean Thilmany is a science and technology writer in Saint Paul, Minn.

Engineers are needed because the 3D shapes that make up a part are inherently complex and assembling them into a complete product even more so. Parts have a limited range of motion, which only add to the complexity.

As such, assembly planning has resisted the automation that has long been part of the manufacturing world. While attempts have been made and algorithms do exist, they are “less than spectacular,” according to Yunsheng Tian, a Ph.D. student at the Computer Science and Artificial Intelligence Laboratory (CSAIL) at the Massachusetts Institute of Technology. He is lead author of the paper “Assemble Them All: Physics-Based Planning for Generalizable Assembly by Disassembly,” presented at SIGGRAPH Asia 2022.

Become a Member: How to Join ASME

Automating assembly instructions would slash costs. It would also allow manufacturers to quickly swap out assembly lines so they could build various products on one line rather than devoting a whole line to one product.

In a big step toward automating assembly planning, researchers have developed an algorithm that can automatically generate assembly plans for all types of products. The algorithm determines the order for multipart assembly, then searches for a motion path for each step to create an overall assembly plan. It can be generalized to a wide range of complex real-world assemblies, said Tian.

Researchers from Autodesk Research, CSAIL, and Texas A&M University collaborated on developing the algorithm as a way to automatically, accurately, and efficiently assemble products that cover a range of complex assemblies. It determines the order for multipart assembly, and searches for a realistic motion for each step, according to the researchers.

Using Section IX with other Construction Codes? We have a course on that.

The algorithm will help engineers as they work to find the best way to assembly a part, said Karl Willis, a senior research manager at Autodesk Research, in a statement. In the future it could automatically generate assembly instructions. It solves 80-part assemblies within several minutes, so multiple parts could be made on one assembly line that is quickly swapped out..

The method leverages the “assembly-by-disassembly principle” and physics-based simulation to explore a reduced search space, according to Tian. It solves 80-part assemblies within several minutes, and generalizes to rotational assemblies.

To test their algorithm, the researchers compiled data on thousands of industrial assemblies that required a range of motions, Tian said. Using physics-based simulation, the algorithm applies different forces to, for example, a screw that needs to be affixed to a rod. In the disassembly stage, the algorithm finds the screw’s motions that will best fit it to the rod. It then reverses the disassembly path to get an assembly solution from individual parts, he added.

Listen to Our Podcast: Six Sigma and Mechanical Engineers

The team has yet to determine how much automating assemblies could help a manufacturer’s bottom line, but they believe the number could be large. As an example, IKEA furniture has step-by-step instructions, manually authored by people. With this algorithm, it may be possible to automate those instructions.

The algorithm was tested only on rigid objects and performed well. Future work will deal with soft, deformable assemblies. The team next may explore devising a robotic setup to assemble items with the goal of making an assembly line that could assemble a part without humans.

Jean Thilmany is a science and technology writer in Saint Paul, Minn.

.png?width=854&height=480&ext=.png)