3D Printing the Heart of the Matter

3D Printing the Heart of the Matter

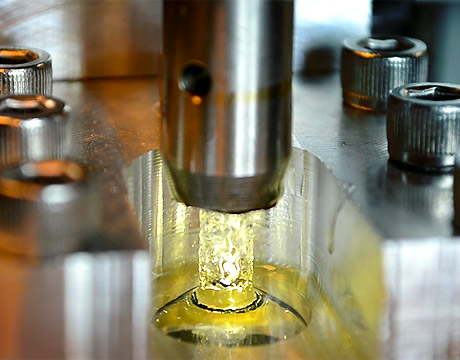

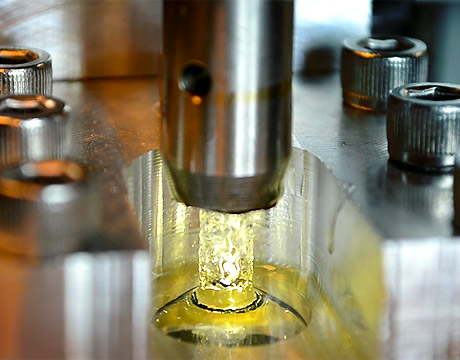

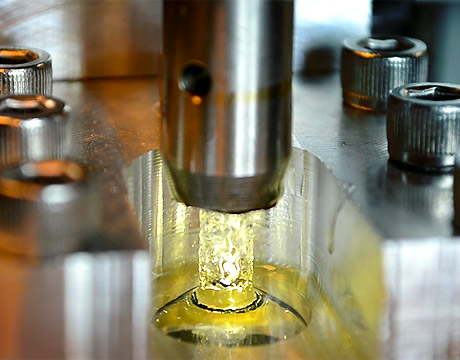

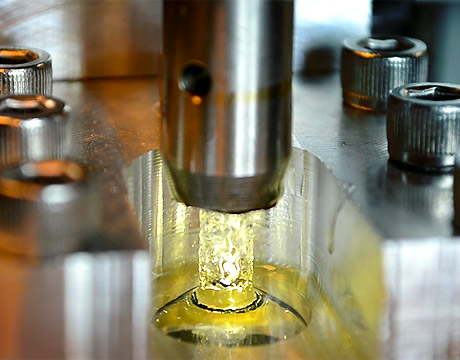

3D printing a flexible biodegradable stent customized for a specific patient’s body. Image: Northwestern University

You can appear to be in the best shape of your life—eating well, exercising, keeping your weight in check—and then you get a symptom, maybe even a painful experience and then the news. You have a heart issue. Stents are commonly used to treat blocked arteries. Now a 3D printing process might just take stents to a different level.

As Cheng Sun, associate professor of mechanical engineering at Northwestern University, explains, blood vessels get clogged and create a narrowing of the blood vessel and, furthermore, that can create a problem with blood circulation. “The stent comes in to expand the clogged region, not unlike a plumber,” he says.

Sun says his collaborator Guillermo Ameer, a professor of biomedical engineering and a professor of surgery at the school, actually designed the materials that can degrade in the body. “I was working on 3D printing and with 3D printers you have the freedom to control the shape and the rigidity of the stent,” he says.

Sun aimed to create customized stents for individual patients. “We talked to pediatricians and they said that the normal metal stent doesn’t accommodate for growth. With people being so different physically, being able to print for the individual could offer a huge advantage,” he says.

They decided to use the 3D printing technique of projection micro-stereolithography.

“For the 3D printing process, it starts with what I call a photopolymer—it’s in liquid form—and the unique aspect is you shine light on to that litmus and it’s similar to photolithography,” Sun explains. “Whenever the liquid exposes to the light, it will be converted into the solid. Think projecting an image like in a movie theater—now we project image onto this liquid in this case. Whatever the shape of light will define the shape of the solid. If you repeat the process, layer by layer, you create a three dimensional structure,” he adds.

According to him, for the 3D printing process, they start with the design as a 3D model in a computer. “As we generate the model, then it’s just a side step to make many layers and send the individual layer to the printing process,” he says.

Since the metal typically used for stents can be treated as a foreign object by the body, the hope is the polymer, which is also biodegradable, could be more compatible when it comes to the blood vessel. Presently, they’re looking at studies to see how the blood will behave. The printed stent is currently around 5 mm in diameter and the lens is currently up to 4 cm long, he says.

“The project started about three years ago and we’re out to provide functionality, resolution, accuracy, and reasonably good mechanical strength,” says Sun. “A main problem is viscosity for the printer, where we need to modify the process to make it more friendly to a photopolymer that offers high viscosity. This project is a challenge that continues and hopefully has a great ending for people who need stents.”

Eric Butterman is an independent writer.

As we generate the model, then it’s just a side step to make many layers and send the individual layer to the printing process.Prof. Cheng Sun, Northwestern University