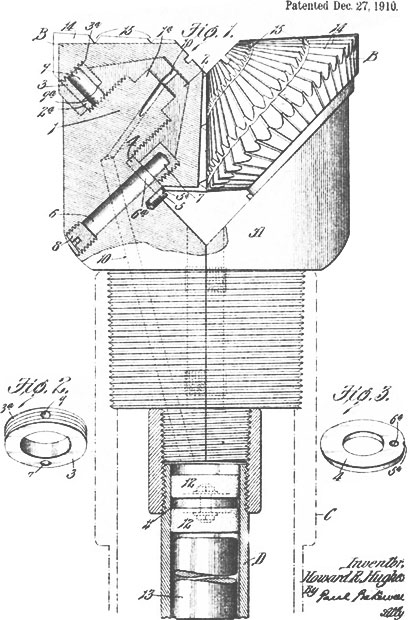

#246 Hughes Two-Cone Drill Bit

1909

Key technology that allowed drilling through medium and hard rock, tapped vast oil reservoirs much deeper below the surface than previously possible, and significantly improved the efficiency and cost of drilling

Unlike the fishtail bit, the Hughes two-cone bit rolled in a true circle, crushing and grinding the rock. This rolling motion allowed the cutting edges to chip the rock, one edge after another. Significantly, the cutting edges were designed so they would avoid falling into previous cuts, preventing what is known as tracking. This enabled each edge to continuously crush a new portion of the rock. The absence of pure scraping of the fishtail bit allowed the Hughes Two-Cone Drill Bit to drill faster and further before sharpening. The detachable cutters could be removed for sharpening or replacement when dull. Two-Cone Bit Accepting Plaque

The bottom of the drill hole, as formed by the operation of the bit, was a perfect seat for a water-tight joint, preventing leakage after the casing had been set. The Hughes Two-Cone Drill Bit ushered in a new era of abundant, inexpensive fuel and laid the foundation for the automobile age.

Landmark Location

Baker Hughes/Hughes Christensen

Two-Cone Bit Cowboys

9110 Grogan's Mill Road

The Woodlands, TX

Visiting Info

An early production Two-Cone Drill Bit and the ASME Landmark Plaque are on permanent display in the entrance lobby of Baker Hughes Drill Bit Technology Facility, 9110 Grogan's Mill Road, The Woodlands, Texas. For information or directions, call (281)363-6771.

Ceremony Notes

August 10, 2009

Ceremony Notes

Ceremony took place at Baker Hughes' Drill Bit Technology Facility, in The Woodlands, Texas, on August 10, 2009. Attended by Baker Hughes/Hughes Christensen employees and executives, ASME Members and staff, including those of IPTI and the South Texas Section. The guests were addressed by the following speakers: Scott Schmidt, President, Hughes Christensen Product Line, extended a warm welcome to the attendees; Bobby Grimes, ASME Vice President, IPTI, and Manager, Technology Services, Baker Hughes, Technology / Hughes Christensen, introduced and MC'd the ceremony; Keith Thayer, ASME Past President, introduced certain ASME members and awarded the bronze Historic Mechanical Engineering Landmark plaque; Glenn MacDonald, ASME-South Texas Section's History & Heritage Chair, represented the Committee on History & Heritage and described its program; Bob Cunningham, Retired Researcher, Hughes Tool Company, described his experience of working with Howard Hughes, Sr. and Walter Sharp and the development of the improved drilling devices; and Derek Mathieson, President, Products & Technology, Baker Hughes, accepted the plaque award from Keith Thayer.