Tiny Holes Improve Boiling Performance

Tiny Holes Improve Boiling Performance

Engineers compelled bubbles to jump from a heated plate during boiling to enhance heat transfer. Their research suggests microstructures could increase power plant efficiency.

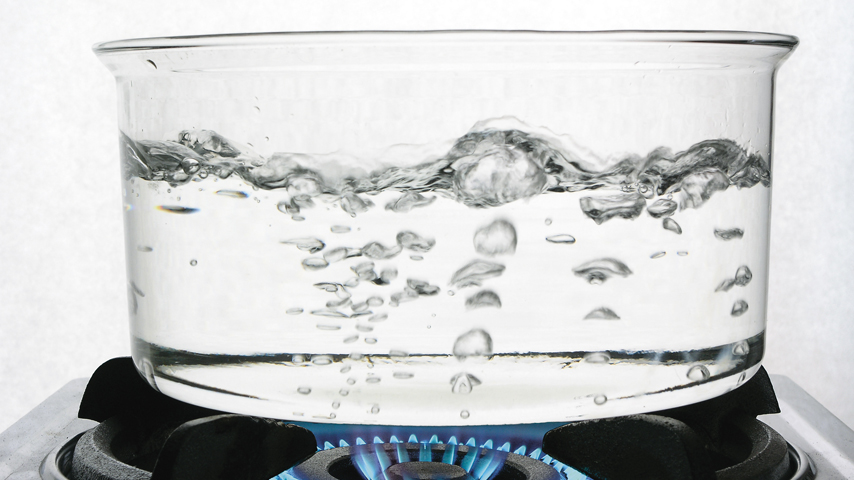

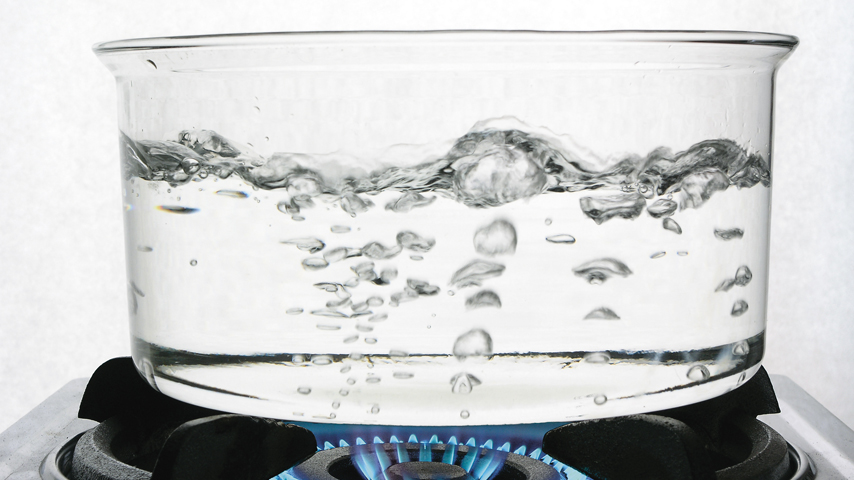

In boiling water on a stovetop, energy from the flame or heating element converts the water in the pot to tiny bubbles, promoting continual heat transfer. If the stovetop is turned up too high, however, excess thermal energy overwhelms the water and forms one continuous bubble, or vapor blanket, at the bottom of the pot, creating a barrier between the heat source and the water.

“When aggressively boiling at a really high temperature, the bubbles form a continuous blanket of vapor and once that happens the boiling is ruined because the water is not touching the heated surface anymore,” said Jonathan Boreyko, an associate professor, and John R Jones III Faculty Fellow in mechanical engineering at Virginia Tech.

Boreyko’s interest in boiling water has nothing to do with making pasta, however. He and a team of fellow researchers at Virginia Tech have been looking at ways to improve the transfer of heat into water, which has important applications in power plants and other facilities. A vapor blanket, for instance, obstructs heat transfer and significantly reduces plant efficiency. Consequently, the steam appliances must operate within a specific fluid temperature range to prevent a vapor blanket from forming.

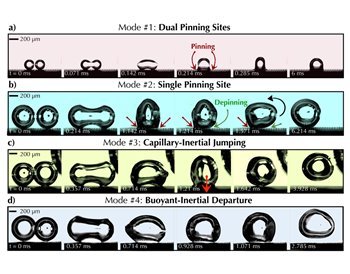

The team has discovered that adding microstructures to the boiling surface prompts bubbles to merge and detach at microscopic sizes, 10 to 100 times smaller than traditional bubbles. This phenomenon, referred to as jumping bubbles, more efficiently moves thermal energy away to make room for more heat transfer.

Boreyko has been working on the merging of different types of water structures for some time. Early in his career, Boreyko discovered jumping dew droplets. Using a high-speed camera, he observed dew droplets grow and “convert the surface tension force, released as two droplets merge together very quickly,” he said, “to catapult the droplets off the surface in a jumping motion.”

A few years later, Boreyko’s graduate student Farzad Ahmadi discovered jumping ice crystals. Unlike jumping dew droplets or bubbles, driven by surface tension forces, jumping ice crystals result from electric attraction to a polarizable material, such as a water droplet above the frost. Completing the trilogy of jumping water in all three states, Boreyko and graduate student Hyunggon Park delved into the potential of jumping water vapor.

The researchers optimized the boiling surface to regulate bubble formation and proximity, achieving an optimized bubble size that moved away from the surface at a micrometer diameter scale.

“Drilling tiny holes into a metal plate and heating it will cause bubbles to grow inside the hole, because the hole’s a little bit hotter and the bubbles prefer the sharp corners of the hole,” Boreyko said. By closely spacing the holes, bubbles expanded and merged with neighboring bubbles rapidly and at a reduced size compared to bubbles generated on a flat, unmodified plate.

“Drilling tiny holes into a metal plate and heating it will cause bubbles to grow inside the hole, because the hole’s a little bit hotter and the bubbles prefer the sharp corners of the hole,” Boreyko said. By closely spacing the holes, bubbles expanded and merged with neighboring bubbles rapidly and at a reduced size compared to bubbles generated on a flat, unmodified plate.

The discovery of jumping bubbles revealed enhanced boiling effectiveness, not only through the facilitation of increased thermal energy transfer but also by extending the boiler’s operating range to higher temperatures. Moving bubbles away from the boiling plate meant that the upper limit temperature could surpass that of traditional boiling, as the risk of forming a vapor blanket diminished significantly.

“There is a wider temperature range where the boiling should still work, because bubbles are jumping off before they can make a vapor blanket. This could expand the range of conditions for boiling to get to a new performance ceiling,” Boreyko said.

The Virginia Tech team is now tasked with trying to quantify the increase in heat transfer and the enhancement of system performance between a standard plate and the optimized plate with tiny close-spaced holes.

The research team is looking to work with industry experts to understand how scaling deposits form over time and design a boiling plate to facilitate jumping bubbles and curb scaling to increase the longevity of the appliance.

“Nanoscale or even small micro holes in the boiling plate aren’t going to be reliable long term because the scaling will fill in the holes,” Boreyko said. “With a very large micro pattern, the hypothesis is that it could be durable for a long time.”

Virginia Tech’s research on jumping bubbles could revolutionize heat transfer dynamics. By strategically manipulating the boiling plate, bubbles are forced to merge and jump away faster and smaller than traditional bubbles, optimizing thermal energy transfer. This discovery extends beyond efficiency; it broadens the operating temperature range by mitigating the risk of vapor blankets at the boiling plate. The research team now hopes to measure the improved heat transfer performance and examine real-world applications, hinting at a transformative leap in boiling technology.

Nicole Imeson is a writer in Calgary, Alberta.

“When aggressively boiling at a really high temperature, the bubbles form a continuous blanket of vapor and once that happens the boiling is ruined because the water is not touching the heated surface anymore,” said Jonathan Boreyko, an associate professor, and John R Jones III Faculty Fellow in mechanical engineering at Virginia Tech.

Boreyko’s interest in boiling water has nothing to do with making pasta, however. He and a team of fellow researchers at Virginia Tech have been looking at ways to improve the transfer of heat into water, which has important applications in power plants and other facilities. A vapor blanket, for instance, obstructs heat transfer and significantly reduces plant efficiency. Consequently, the steam appliances must operate within a specific fluid temperature range to prevent a vapor blanket from forming.

The team has discovered that adding microstructures to the boiling surface prompts bubbles to merge and detach at microscopic sizes, 10 to 100 times smaller than traditional bubbles. This phenomenon, referred to as jumping bubbles, more efficiently moves thermal energy away to make room for more heat transfer.

Boreyko has been working on the merging of different types of water structures for some time. Early in his career, Boreyko discovered jumping dew droplets. Using a high-speed camera, he observed dew droplets grow and “convert the surface tension force, released as two droplets merge together very quickly,” he said, “to catapult the droplets off the surface in a jumping motion.”

A few years later, Boreyko’s graduate student Farzad Ahmadi discovered jumping ice crystals. Unlike jumping dew droplets or bubbles, driven by surface tension forces, jumping ice crystals result from electric attraction to a polarizable material, such as a water droplet above the frost. Completing the trilogy of jumping water in all three states, Boreyko and graduate student Hyunggon Park delved into the potential of jumping water vapor.

Getting carried away

Surface bubbles typically grow to a millimeter diameter before detaching through buoyancy. Bubbles moving away from the boiling surface carry thermal energy with them, creating space for the formation of more bubbles and additional energy transfer.The researchers optimized the boiling surface to regulate bubble formation and proximity, achieving an optimized bubble size that moved away from the surface at a micrometer diameter scale.

ASME Learning & Development

Learn practical, job-relevant skills for sustained career-long success with ASME’s flexible training for engineers and technical professionals.

The discovery of jumping bubbles revealed enhanced boiling effectiveness, not only through the facilitation of increased thermal energy transfer but also by extending the boiler’s operating range to higher temperatures. Moving bubbles away from the boiling plate meant that the upper limit temperature could surpass that of traditional boiling, as the risk of forming a vapor blanket diminished significantly.

“There is a wider temperature range where the boiling should still work, because bubbles are jumping off before they can make a vapor blanket. This could expand the range of conditions for boiling to get to a new performance ceiling,” Boreyko said.

The Virginia Tech team is now tasked with trying to quantify the increase in heat transfer and the enhancement of system performance between a standard plate and the optimized plate with tiny close-spaced holes.

Scale matters

A practical challenge encountered in boiling water to generate steam is scaling. Impurities in the water are left behind during the evaporation process and accumulate on the boiling plate. This scaling acts as an insulator, impeding thermal energy transfer to the fluid. With an optimized boiling plate and elevated operating temperatures, scaling mimics the effect of the vapor blanket, restricting heat transfer below its original performance.The research team is looking to work with industry experts to understand how scaling deposits form over time and design a boiling plate to facilitate jumping bubbles and curb scaling to increase the longevity of the appliance.

“Nanoscale or even small micro holes in the boiling plate aren’t going to be reliable long term because the scaling will fill in the holes,” Boreyko said. “With a very large micro pattern, the hypothesis is that it could be durable for a long time.”

Virginia Tech’s research on jumping bubbles could revolutionize heat transfer dynamics. By strategically manipulating the boiling plate, bubbles are forced to merge and jump away faster and smaller than traditional bubbles, optimizing thermal energy transfer. This discovery extends beyond efficiency; it broadens the operating temperature range by mitigating the risk of vapor blankets at the boiling plate. The research team now hopes to measure the improved heat transfer performance and examine real-world applications, hinting at a transformative leap in boiling technology.

Nicole Imeson is a writer in Calgary, Alberta.